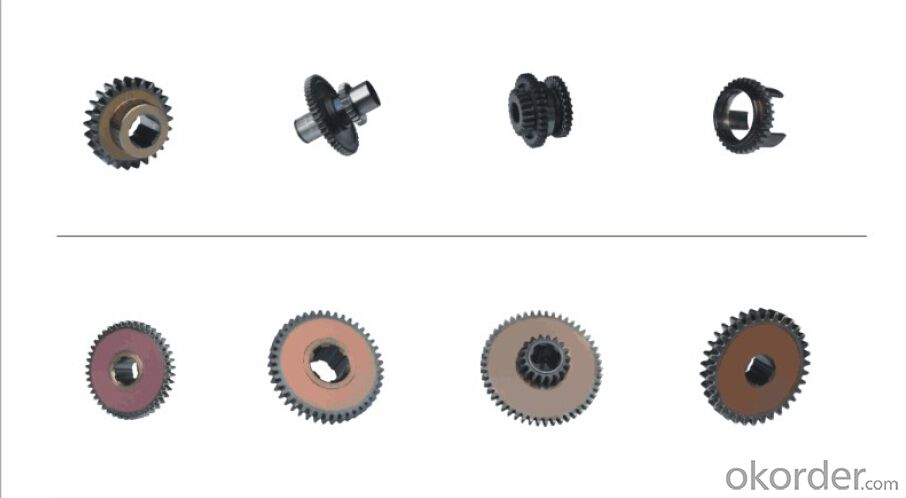

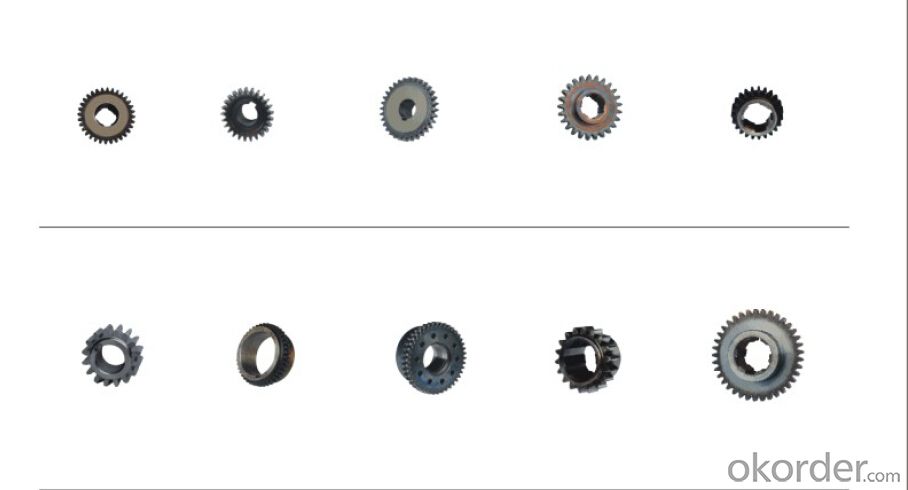

Gear planetary gear OEM hobbing,shaving,grinding for machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Material: | Steel,as requirements | Processing: | Forging | Pressure Angle: | 20 |

| Place of Origin: | Zhejiang China (Mainland) | technology of material: | forging | technology of machining: | hobbing,shaving,grinding |

| heatreatment: | nitriding,carburization | OEM: | is acceptable |

Packaging & Delivery

| Packaging Detail: | packed in carton |

| Delivery Detail: | 70days |

Specifications

1.produce as drawings

2.material will be as requirements

3.strictly quality control

4.OEM is acceptable

Products information:

1. suitable for many sorts of transmission system, such as agriculture tractor, wind power, truck and other industry zone.

2. material and precision can be as requirements.

3. we have complete gear machining equipments: gear hobbing machine, shaving machine, gear shaper, gear grinding machine, and our own heat treatment center. all of the production procedure are strictly controlled by ourselves, no cooperation procession, so we can sure the final products to meet your requirements.

4.each processing, strictly quality control

5.certificate: ISO9001, ISO/TS16949

- Q: For planetary gears, the fixed ring gear connects the sun wheel and the planet carrier, but does it still move?

- (4) before and after the star frame ring gear assembly; according to the different number of forward stalls, the Simpson type planetary gear box is divided into Simpson type 3 speed planetary gearbox and Simpson Thompson type 4 gear planetary gear box two.

- Q: Are gears and gear rings a kind of thing?

- A cylindrical or conical gear is obtained when the teeth are machined on the outer surface of a cylinder or cone;The teeth are machined on the inner surface of the hole to obtain the gear ring;When the teeth are machined on the plane, the rack is obtained;

- Q: How does the gear radial runout tolerance affect the gear drive?

- The radial runout of the gear ring is caused by the misalignment between the center of the gear circle center and the center of the gear hole (or shaft) when the gear is machined (this is the main reason and the main influencing factor).

- Q: How to find the damage of automobile flywheel ring

- First, when the engine is started, the gear crash is heard, because the gear on the flywheel is worn and deformed, and the pinion of the starter gear can not be engaged in place, and the teeth are struck.

- Q: How to deal with the bite gear of starter drive gear and flywheel ring gear?

- Suggest replacing gears!2, the starter gear and flywheel teeth are loose, gear fixed position due to force displacement, resulting in tooth biting!It is recommended to be tested and fixed in detail!

- Q: In the processing of gear ring down end angle is cumbersome, requires a lot of hard work, Master Wang, senior, Ariadne, how fast, mass production? What kind of chamfer do you use? What knife do you use? We take out sun drying, learn from each other, study together, improve efficiency ~ ~ ~!

- Chamfering can be made in Tianjin by chamfering machines, which can be adjusted according to different products. Chamfering is the burr of the chamfering surface. Corrected to a small edge

- Q: The clearance between the slewing ring gear and the drive pinion

- And gear accuracy, installation center spacing is related to ~! See the manual ~!

- Q: The number of planet gear is 20, the drive ratio is 7.5. The number of teeth of solar wheel and ring gear is required

- You drive ratio is really strange, I figure out the sun gear number of 6 points Oh.

- Q: Can the planetary gear reducer require no gear ring? The solar wheel is active and the planet carrier outputs

- (1) Simpson Simpson type planetary gear box, planetary gear box is composed of a Simpson type planetary gear mechanism and relative shift operation components, most automatic transmissions are using this planetary gearbox; Simpson type planetary gear mechanism is a planetary gear mechanism is very famous, it is composed of two internal meshing planetary gear mechanism combination, its structure is characterized by (1) before and after the two planetary sun gear is connected into a whole, called the sun before and after the wheel assembly (2) before a planetary planetary frame and a planetary gear ring connected to the other as a whole, called on star frame and a rear ring gear assembly (3) and the output shaft is usually the former planet carrier and the ring gear assembly (Figure 7-4). So, the agency became the 4 independent components (1) before the ring gear (2) before and after the sun wheel assembly (3) after the star frame (4) before and after the star frame ring gear assembly; according to the different number of forward stalls, the Simpson type planetary gear box is divided into 3 Simpson gear planetary gear transmission and Simpson Thompson type 4 gear planetary gear box two.

- Q: What's the relationship between the number of teeth on the flywheel ring of the engine and the election? I know that it is engaged with the starter. Is it possible to choose a small starter to start fast? How can I choose this?

- This can not be arbitrarily selected, choose a few teeth seriously affect the motor use, may be burned, as stipulated in the diesel engine has a specified number of the diesel engine gear, such as Yulin 6105QC is -110 gear

Send your message to us

Gear planetary gear OEM hobbing,shaving,grinding for machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords