Gear planetary sun gear OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Material: | Steel,as requirements | Processing: | Forging | Pressure Angle: | 20 |

| Place of Origin: | Zhejiang China (Mainland) | technology of material: | forging | technology of machining: | hobbing,shaving,grinding |

| heatreatment: | nitriding,carburization | OEM: | is acceptable |

Packaging & Delivery

| Packaging Detail: | packed in carton |

| Delivery Detail: | 70days |

Specifications

1.produce as drawings

2.material will be as requirements

3.strictly quality control

4.OEM is acceptable

Products information:

1. suitable for many sorts of transmission system, such as agriculture tractor, wind power, truck and other industry zone.

2. material and precision can be as requirements.

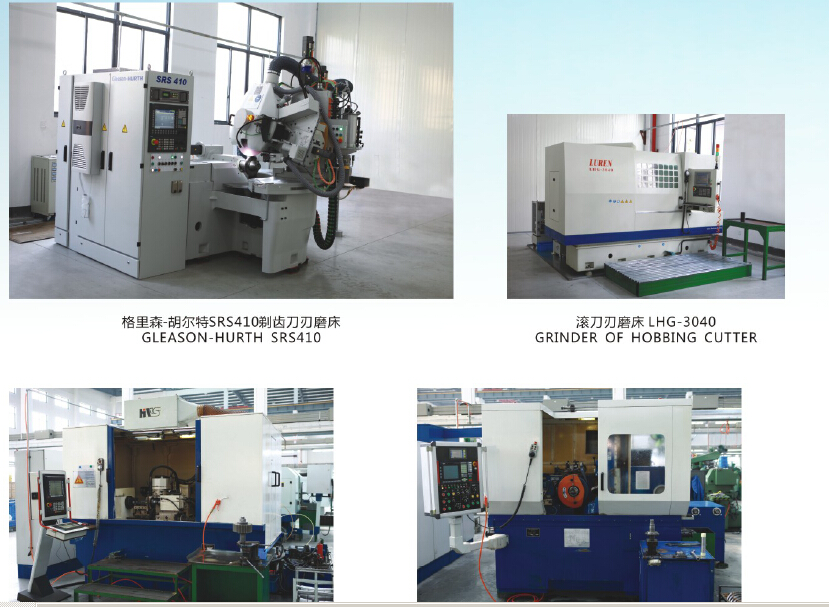

3. we have complete gear machining equipments: gear hobbing machine, shaving machine, gear shaper, gear grinding machine, and our own heat treatment center. all of the production procedure are strictly controlled by ourselves, no cooperation procession, so we can sure the final products to meet your requirements.

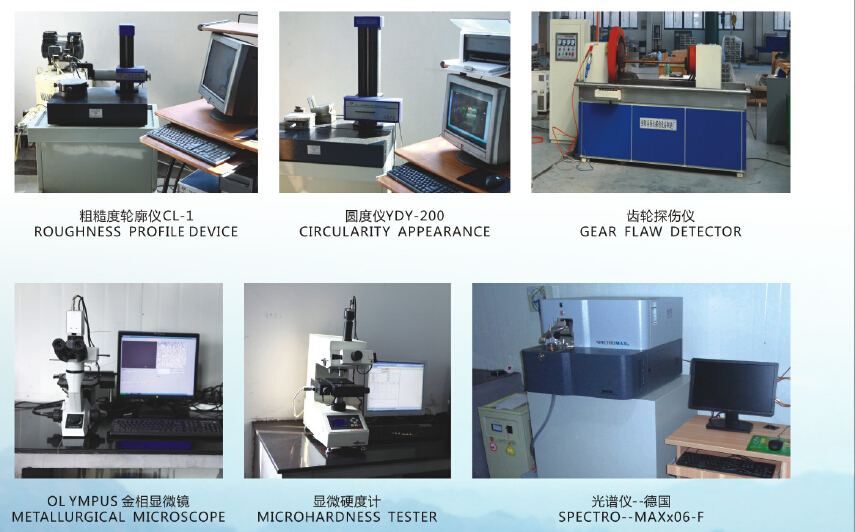

4.each processing, strictly quality control

5.certificate: ISO9001, ISO/TS16949

- Q: Planetary gear reduction problem. The outer gear ring is fixed with 80 teeth, the planet tooth is 30 teeth, the center tooth is 20 teeth.1, can the meshing drive.2, the planet carrier input power, the sun tooth output power. What is the speed ratio?

- The number of teeth of the star wheel and the transmission ratio never mind

- Q: I was wrong during the exam. I hope you can tell me, thank you.

- Several hammers called it inHeat up, contract cold, burn for about 10 minutes

- Q: A few days ago to a car POLO, accidentally remove the engine after the ring gear crankshaft behind the crank position sensor to get down, now the engine installed wouldn't burn, a question that is not the ring gear according to the previous position of the good, the master has repaired this a car I ha, very urgent!!!!!!!! Tell me in detail where it is there, the most important is the installation of the ring gear, the engine is 1.4 double cam shaft, 16 valve.

- Crankshaft position sensor: one of the most important sensors in the electronic control system of an engine. It provides ignition time (ignition advance angle) and signals confirming the position of the crankshaft, which is used to detect the upper dead center of the piston

- Q: 305 modern excavator slewing ring to install

- Just watch out for safety. Wish you a smooth change! A vice factory slewing support price of 6000-7000 yuan between.

- Q: How is the thickness of the outer ring (outer diameter and internal diameter) determined?

- According to the torque transmission size is different, it needs outside diameter and internal difference, the thickness is not the same

- Q: Engine model CLS, crankshaft sensor timing ring with crankshaft alignment

- According to certain rules, it can be transformed into electrical signals or other forms of information output to meet the requirements of information transmission, processing, storage, display, recording and control.

- Q: The ring gear of planetary gear structure, planetary gear, and planetary gear, the steering of the sun wheel

- The ring gear and the planetary gear are always the same direction,

- Q: How many teeth ring for 11 teeth starter?

- 1, 11 teeth starter with 110 teeth or so gear ring.2, because the starter gear and engine flywheel gear ring transmission ratio is generally about 1 to 10, so the 11 teeth starter with 110 teeth or so gear ring.3, gear ring meaning: flywheel gear ring is heated after inserted on the outer edge of the flywheel, cooled after fastening on the outer edge of the flywheel, used to engage with the starter gear, drive crankshaft rotation, start the engine.

- Q: Where is the axle ring in the car?

- You say the ring gear is ABS induction ring bar, on the inside of the wheel, half axle

- Q: Is the flywheel ring prone to failure?

- Breakdown wear of starter1, when the motor internal transmission parts appear Songkuang such as fork or the middle pin hole for long-term use and wear the fork on both sides of cylinder wear serious deformation, fork top pin Songkuang if the individual or simultaneously will cause the driving torque is consumed and invisible closed time operation and one-way clutch switch contacts the synchronous starter has started to rotate and one-way clutch and gear engagement ring is not yet in place resulting in milling.

Send your message to us

Gear planetary sun gear OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords