Gear shaft OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Material: | Steel,as requirements | Processing: | Forging | Pressure Angle: | 20 |

| Place of Origin: | Zhejiang China (Mainland) | technology of material: | forging | technology of machining: | hobbing,shaving,grinding |

| heatreatment: | nitriding,carburization | OEM: | is acceptable |

Packaging & Delivery

| Packaging Detail: | packed in carton |

| Delivery Detail: | 70days |

Specifications

1.produce as drawings

2.material will be as requirements

3.strictly quality control

4.OEM is acceptable

Products information:

1. suitable for many sorts of transmission system, such as agriculture tractor, wind power, truck and other industry zone.

2. material and precision can be as requirements.

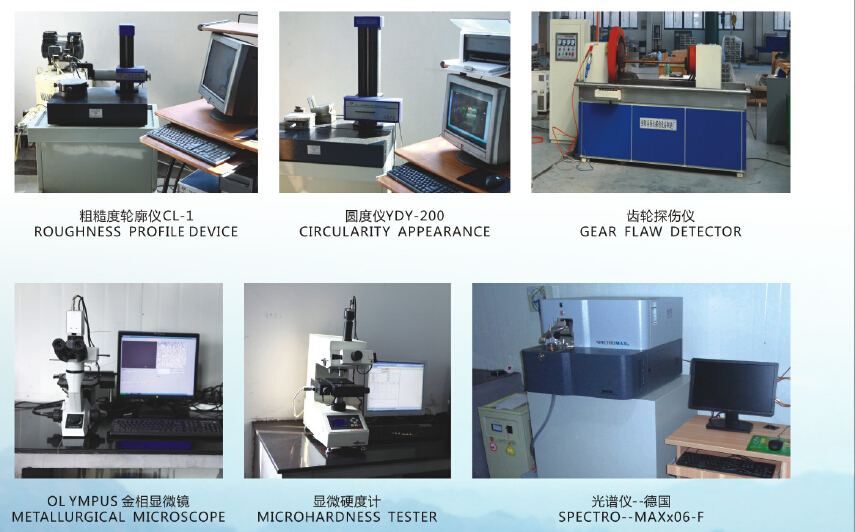

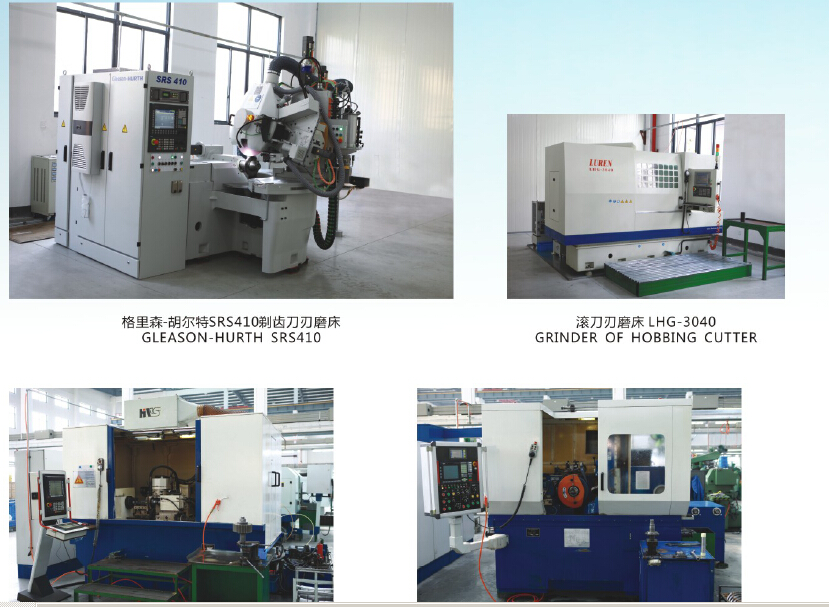

3. we have complete gear machining equipments: gear hobbing machine, shaving machine, gear shaper, gear grinding machine, and our own heat treatment center. all of the production procedure are strictly controlled by ourselves, no cooperation procession, so we can sure the final products to meet your requirements.

4.each processing, strictly quality control

5.certificate: ISO9001, ISO/TS16949

- Q: 1115 how many teeth are used when the diesel engine is switched on?

- Disassemble and inspect the suction and hold coils of the motor starter and their contacts

- Q: In synchronous transmission, often combine the ring gear and the normally meshed helical gear made of two bodies (two connected by a spline), this is why? With the ring gear by the torque constant meshed helical gear to pass combining sets, but the combination of gear tooth width and tooth width. Normally meshed helical gear is bigger, this is what reason?

- In the synchronizer gearbox, often combine the ring gear and the normally meshed helical gear made of two bodies (two connected by a spline), this is why? because in gear machining, gear hobbing efficiency is relatively high (compared with the gear, and combined with the existing gear) ""

- Q: Why does the radial runout of the gear ring reveal only the geometric eccentricity of the gear?

- Because the geometric eccentricity (mainly caused by fit clearance) has the greatest impact on the gear ring runout. And the error caused by motion eccentricity should be measured in tangent direction and revealed". For example, the common law line, the variable error, the tooth distance error, etc..

- Q: How does the gear radial runout tolerance affect the gear drive?

- Because the elements that make up the gears are very complicated, a single error of the gear is actually "involved" with other errors

- Q: The number of teeth in my inner ring gear is 80, the modulus is 6, the addendum factor is 0.8, and the root coefficient is 0.25

- I don't care what your ring is, isn't it an array of 44 units on a circle?. It looks like you don't even have a basic array of axes. Select the center axis, the array number of 44, there are two items, one is 90 degrees, one is 360 degrees, do not worry about that 90 degrees, 360 degrees ahead of the angle icon, so that 360 degrees become optional angle. Spot return. Complete the right point. There must be no clearance.

- Q: What is the main reason for the radial runout tolerance of gear ring?

- There are many reasons for the radial runout error of gear ring. The main cause of the radial runout error of gear ring is the geometric eccentricity, that is the gap between the hole of the gear blank and the mandrel of the fixture. If the production of small batch, with as little as possible gap fit (gear hole and mandrel); if large quantities, as far as possible to use expansion type centering method, to eliminate the gap, to reduce the gear jump has a certain role.

- Q: The number of planet gear is 20, the drive ratio is 7.5. The number of teeth of solar wheel and ring gear is required

- That is in direct contact with the center of the planetary gear wheel or tied as the driving link drives a planetary gear, a planetary wheel around its axis of rotation O1-O1, on the other hand, with the development of component H (or tied) around a fixed axis (O-O axis rotary wheel center)

- Q: How many teeth ring for 11 teeth starter?

- 1, 11 teeth starter with 110 teeth or so gear ring.2, because the starter gear and engine flywheel gear ring transmission ratio is generally about 1 to 10, so the 11 teeth starter with 110 teeth or so gear ring.3, gear ring meaning: flywheel gear ring is heated after inserted on the outer edge of the flywheel, cooled after fastening on the outer edge of the flywheel, used to engage with the starter gear, drive crankshaft rotation, start the engine.

- Q: In differential planetary gears, the sun wheel and gear ring are used as the driving wheels. The input speed is ns and NR respectively, and the input power is Ps and Pr respectively. How about the force of the planet carrier as the output?

- The torque of each shaft can be calculated by the formula above, the transmission ratio can also be calculated: MN2=MN1 * I *. ETA: efficiency of 1 axis and 2 axis;

- Q: What is the cause of the serious wear of the flywheel ring gear of the engine?

- The processing quality does not meet the requirements of the drawings, the balance of bad performance, the end of the flywheel axial or circumferential radial runout is too large, so that the two plane cannot smooth joint friction is not uniform, so that the flywheel wavy.When the flywheel rotates, because the clutch is in the separation and the combination instantaneous and the flywheel plane has the rotational speed difference, causes these two relative sliding, causes the flywheel work surface to produce the attrition. The plane of the flywheel will be partially ablated and hardened due to the high temperature generated by the high velocity friction.

Send your message to us

Gear shaft OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords