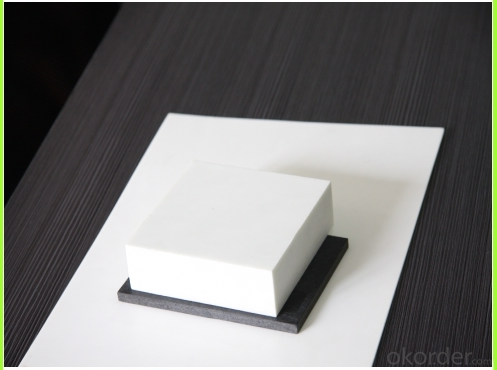

SMC Sheet with Glass Fiber Roving 2400 Tex

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SMC is the short form of sheet mounding compound. This is a raw material for mold pressing. The core is chopped strand and unsaturated polyester resins paste that are covered by LDPE & HDPE sheet. It is 3mm-6mm thick , 600mm-1200mm wide and packing in rolls or boxes. When using , be sure to cut , weigh , uncover film, and join in the heat up mould, after adding high pressure and preserve a time, then you can take off membrane to get the product.

Feature

Higher mechanical strength

Excellent leak-proof electrical

Excellent thermal stability, chemical corrosion resistance

Low water absorption, good dimensional stability, war page small

Reliable arc resistance and voltage withstand, high dielectric strength

Specification

Product name | Fiberglass Reinforced Polyester Corrugated Sheet |

Material | High-performance protective film, unsaturated polyester resin, fiberglass |

Layer | 1 layer |

Width | 900mm,930mm,1100mm |

Thickness | 0.8mm,1.0mm,1.2mm,1.5mm,2.0mm,3.0mm |

Length | 5800mm,11800mm or customized according to requirement of customers |

Color: | Clear, Red, Yellow, Green and opal |

Guarantee: | 10 years |

Certification: | ISO9001 SGS ROSH |

Delivery time | 5-7days(general) depend on the style and quantity |

detail features | 1.The light transmission It is between 60-85%. Light through FRP lighting sheet scatters and is mild. It will not form a light band so as to make the indoor brighter. |

Advantage

Solution of wood steel plastic meter box easy to aging, easy corrosion, poor insulation, poor cold resistance, poor flame retardant, the short life of the shortcomings

Absolute seal waterproof performance, corrosion resistance

Beautiful appearance, long service life

Application

1. Application in automobile industry

(1) Suspension parts, front and rear bumpers, instrument panels and the like

(2)The engine cover under parts such as air conditioner shell: wind shield, the intake manifold cover, Fan vanes ring, heater cover, tank parts, brake system components, and the Battery bracket, engine noise barriers and so on

2. Application in electric industry and communication engineering

3. Application in rail vehicle

SMC railway vehicles, window frames, bathroom components, seat, coffee table tops, SMC compartment wall and SMC roof

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

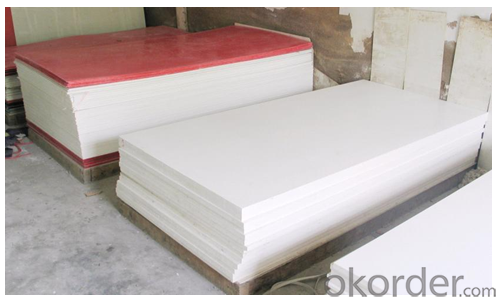

FACTORY

PACAKGE

- Q: What material is the resin composite manhole cover made of?

- Glass fiber yarn, filler, resin, curing agent, accelerator, mold, etc.

- Q: Where are the differences between the products made of stone and resin?

- The real stone is natural and is generally used for outdoor decoration. The products made of resin materials are synthetic, such as artificial marble, kitchen countertops, toilet toilets, washbasin and bedplate.

- Q: Is the quality of the resin wall the same?

- From the material, divided into SMC sheet processing background wall and BMC group processing background wall, in which the SMC background wall high strength, board size can do relatively big, and BMC background wall can only do small size board.

- Q: What are the raw materials for composite manhole covers?

- Because the SMC polymer resin composite covers are made of resin and SMC polymer sheet pressing, without reinforcement than usual covers light weight 2/3, but this kind of SMC polymer resin composite covers and not because of its weight and reduce its carrying capacity, SMC polymer resin composite well cover bearing is three times that of ordinary resin composite manhole cover bearing, up to 90 tons

- Q: What is polymer composite cable trench cover plate?

- But on the actual sales market, the BMC material plus steel pressed into the cover plate, glass fiber reinforced plastic grille also become high polymer composite material cover plate.

- Q: Seeking better SMC manufacturers in the industry, it is best to write more, thank you!

- I don't quite understand your question. SMC has only one manufacturer. I'm the agent of SMC. You don't know much about it

- Q: What is a sheet of material? Is it plastic? What is it used for?

- The sheet refers to the resin (or in the process of using monomer polymerization) as the main ingredient, such as plasticizers, fillers, lubricants, additives such as colorants as auxiliary components, can flow in the process of forming materials. In the material industry, SMC is commonly known as sheet material, and the full name of Chinese is: sheet molding plastics. The utility model relates to a premix for molding. In the glass fiber reinforced plastic industry, SMC is widely used. The large areas of sheet materials, such as automobile shell, water tank, seat and so on, are generally molded by SMC compression and heating.

- Q: How do you measure the excess of the compound in the house?

- In the case of color SMC, the roving shall be impregnated with resin in a high pigment resin paste. Generally, SMC roving is usually 2400tex, and 4800tex is also useful in a few cases.

- Q: What is the use of resin fiber powder extracted from the circuit board without breaking the law?

- The general concept of glass is hard and brittle objects, not suitable as structural material, but as the thread, the strength is greatly increased and is flexible, with resin to give it shape can finally become excellent timber structure. Glass fibers increase in strength as their diameter decreases. As reinforcing materials, glass fiber has the following characteristics, which make glass fiber use much wider than other kinds of fiber

- Q: Are SMC tablets harmful to the body? Our factory produces SMC. I have contact every day. Is there any odor that is harmful to my health?

- The state is recognized and safe.

Send your message to us

SMC Sheet with Glass Fiber Roving 2400 Tex

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords