SMC Sheet Faced Glass Rock Wool Pipe/White Pipe Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Insulation Blanket:

Glass Wool Blanket Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping. Also complete glass wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1.Light weight and easy to fabricate on job site

2.Excellent thermal, acoustical properties

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

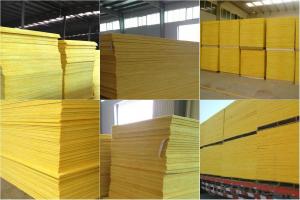

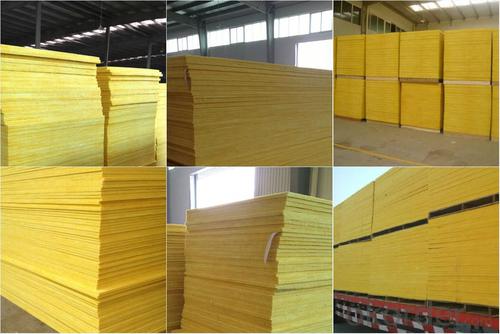

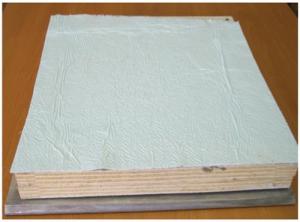

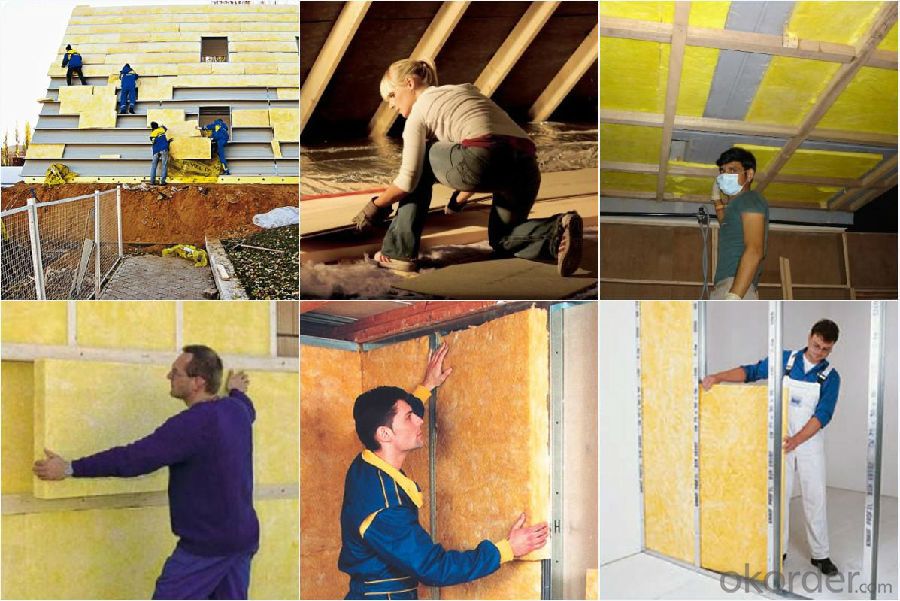

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Performance: high / low temperature resistance, oil resistance, fuel resistance,

Weather resistance, tolerance, etc.

There are a lot of practical use - rockwool products; the following are some of the major areas:

In - rockwool thermoacoustic field used for various types of buildings and the use of thermal insulation, such as housing, Department store,

Office buildings, stadiums, airports, etc..

In the insulation of industrial plants and machinery systems, etc.:

Cool store.

Refinery.

Chemical and petrochemical plant.

Central air-conditioning

Hot water and chilled water system.

For industrial purposes, - rockwool used in many industries:

Industrial furnaces and ovens.

It is widely used in heat preservation and industrial plants, prefabricated houses, portable cabins, warehouses, public facilities, exhibition centers, large shopping centers, the sound absorption, as well as a variety of indoor amusement parks, sports venues, etc..

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What composite material is used for composite manhole covers?

- The composite manhole cover adopts high temperature and high pressure molding technology with high degree of polymerization, large density, good impact resistance and tensile strength, and has the advantages of wear resistance, corrosion resistance, no rust, no pollution, no maintenance, etc..

- Q: What is the difference between plastic die casting and compression molding? Please be specific

- In recent years, press molding has been applied to thermosetting blends such as urea formaldehyde plastics, phenolic resins, epoxy resins, melamine resins, and rubber. Although some materials are available for injection molding, compression molding is still very common. Die casting material is more flexible than plastic material. Many thermosetting materials with high impact (1.0ft lb) and good notched impact strength retention, only in the limit under pressure will flow.

- Q: Does floor heating emit toxic gas?

- One check: check the product radioactive test report, see if the radioactive material is over standardTwo test: Please professionals with instruments for radioactive detection, to see whether and product radioactive test report in line with

- Q: Who knows what is the process flow of FRP splicing water tank?

- Description of production process of glass fiber reinforced plastic water tank:Raw material purchasing: resin paste, glass fiber, laminating, coiling, thickening, cutting, weighing, molding, dressing, drilling, assembling.The prepared raw material is prepared according to a prescribed proportion, and then the paste is stirred into a resin paste; the resin paste and the glass fiber yarn are impregnated with SMC sheets to form a SMC sheet;

- Q: Why outdoor SMC table tennis table longer service life?

- The unique properties of SMC composite material can solve the disadvantages of wooden, steel and plastic electric meter box, such as easy ageing, easy corrosion, poor insulation, poor cold resistance, poor flame retardancy and short service life

- Q: Why is unsaturated polyester resin used in sheet molding? Why don't short fiber moulding plastics use unsaturated polyester resins?

- BMC SMC produced a good sheet or mass, there is a mature thickening process, the temperature should be placed for more than a dozen hours or more time to mature thickening.

- Q: Where can I supply the SMC sheet machine set?

- Qingdao ultra Feng Plastic machinery, buy equipment also with technology and formula, after-sales service is very good

- Q: How is glass fiber reinforced plastic water tank made?

- This is really hard to understand, but I was in the five Yi bought water tank, good quality

- Q: Where is the difference between glass fiber reinforced plastic cable tray and SMC cable trough?

- Process is differentRaw material is different.Product technical parameters are not the sameUse is not the sameThe price is different

- Q: Are SMC tablets harmful to the body? Our factory produces SMC. I have contact every day. Is there any odor that is harmful to my health?

- The state is recognized and safe.

Send your message to us

SMC Sheet Faced Glass Rock Wool Pipe/White Pipe Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords