Rock wool For High Quality Mandrel Wound Pipe Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Rock Wool:

Rock Wool Continuous conveyors transport the mat to the COLD END of

the plant for binder polymerization. The product is then cut to shape and packed for shipping. Also complete rock wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

2.Main features of Rock Wool :

1.Light weight and easy to fabricate on job site

2.Excellent thermal, acoustical properties

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

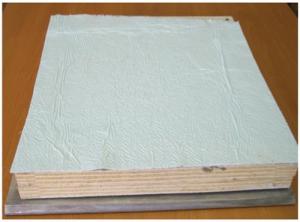

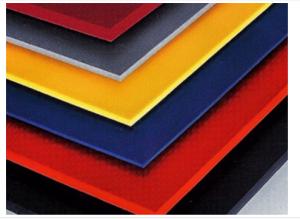

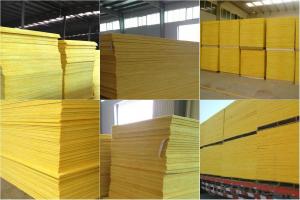

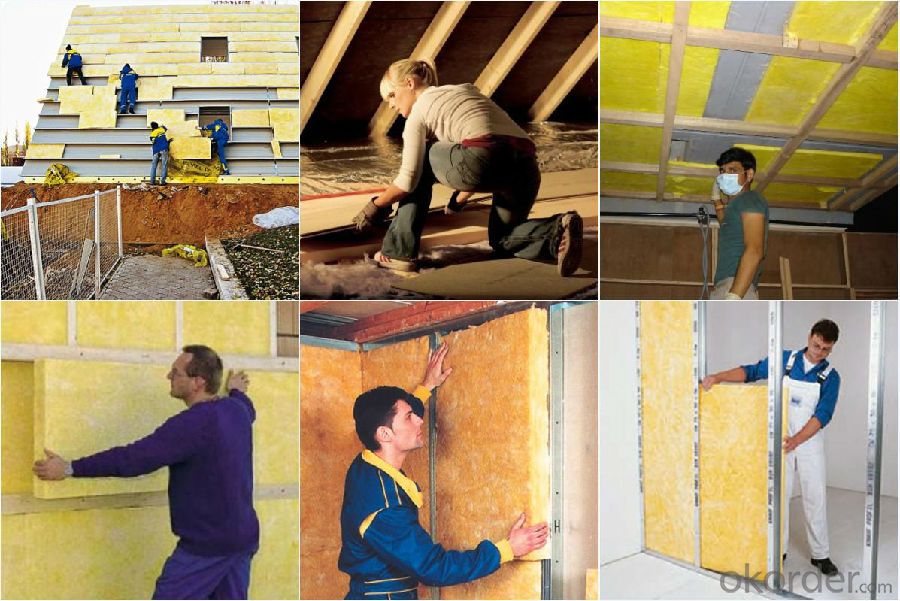

3. Rock Wool Images:

4. Rock Wool Technical Parameters:

Property: High/low temperature resistance, oil and fuel resistance,

weathering resistance, O zone resistance etc.

Rockwool products have many practical uses; the following are some of the main fields:

In the Thermo-acoustical field Rockwool is used for the insulation of buildings of all types and uses, such as houses, department stores,

offices, athletic buildings, airports, etc.

In insulating industrial plants buildings and mechanical systems like:

Cooled stores.

Refineries.

Chemical and Petrochemical Plants.

Central Air conditioning.

Hot water and chilled water systems.

For industrial purposes, Rockwool is used in many industries as:

Industrial furnaces and ovens, Boilers.

It is widely used for heat insulation and sound absorption in industrial workshops, Prefab houses, Portable cabins, warehouses, public facilities, exhibition centers, shopping malls, and a variety of indoor playgrounds, sports stadiums and etc.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Rock wool is one of the large

scale professional investment casting production bases in China.Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What material is the resin composite manhole cover made of?

- Glass fiber yarn, filler, resin, curing agent, accelerator, mold, etc.

- Q: Which is good for SMC composites and honeycomb composites?

- The method of forming a honeycomb structure of a composite material suppresses the sheet material into a corrugated form and then welds or sticks together to form a honeycomb structure;

- Q: What material is SMC? Can it replace ceramics? Can it be made into toilets, basins, urinals and so on?

- Can do, but the cost of mold development is relatively largeSMC sheets are now widely used in sanitary equipment.

- Q: Seeking better SMC manufacturers in the industry, it is best to write more, thank you!

- I don't quite understand your question. SMC has only one manufacturer. I'm the agent of SMC. You don't know much about it

- Q: Why outdoor SMC table tennis table longer service life?

- SMC composite and its SMC molded products have excellent electrical insulation properties, mechanical properties, thermal stability and chemical resistance. Therefore, SMC products have a wide range of applications.

- Q: Is the SMC material poisonous?

- This material is very good, non-toxic, give you a link, you refer to, remember to give a adoption Oh!

- Q: What is the difference between a gain fiberglass and an ordinary omnidirectional antenna?

- SMC and its molded products have the following characteristics: light weight, high strength, precise size, good batch quality and zero shrinkage. With a surface level, mechanization, a high degree of automation, applicable to high surface quality requirements, large output, uniform thickness of the product.

- Q: SMC sheet pressing out the product is not bright, what is the reason?

- Different grades of tree ester use different raw materials, new glycol, propylene glycol content of higher tree ester, made out of sheet pressure product brightness is better, but the higher the cost.

- Q: Where is the difference between glass fiber reinforced plastic cable tray and SMC cable trough?

- Ordinary bridge, pultrusion process, resin, calcium powder, glass fiber and so on, the price is cheaper. Use on common cable

- Q: Are SMC tablets harmful to the body? Our factory produces SMC. I have contact every day. Is there any odor that is harmful to my health?

- Now there are SMC ceiling, the wall products, many hospitals are in use, you can pay attention to professionals Li Laiyi's micro-blog. So, don't be afraid.

Send your message to us

Rock wool For High Quality Mandrel Wound Pipe Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords