SMC Sheet High Sound Absorption Material Rock Wool Blanket with Wire Mesh Water Repellent, Asbestos Free

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

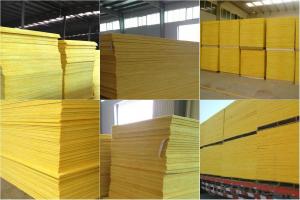

CNBM rock wool blanket with wire mesh Overview:

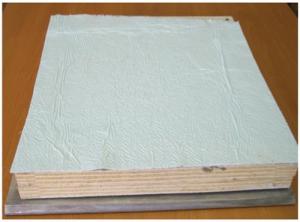

CNBM rock wool blanket with wire mesh is a robust insulation product stitched on one side with galvanized or stainless steel wire mesh and comes in various thickness and density.

CNBM rock wool blanket with wire mesh Product Specifications¼

Density(kg/m3) | Width(mm) | Thickness(mm) | Length(m) | Facing |

60-150 | 600 | 30-200 | 2.5 , 3 , 5 | wire mesh |

We can make special production according to your requirement.

Rock Wool Blanket With Wire Mesh Technical Parameters:

Item | Unit | Index | Standard |

Density | Kg/m3 | 60-200kg/m3 | GB5480.3 |

Average value of fiber | um | 4-7 | GB5480.4 |

Slag ball content (granule diameter) | % | 6 | GB5480.5 |

Volume water absorption | % | 2 | GB/GB16401-1996 |

Heat absorption | % | 1 | GB5480.7 |

Moisture resistivity | % | 98 | B10299-88 |

- Q: What material is the resin composite manhole cover made of?

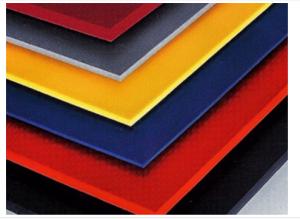

- The raw materials for the composite cover of the colored resin composite cover are alkali free yarn, resin, low shrinkage, color paste, calcium powder, Magnesium Oxide and other additives, which are made by SMC high temperature molding without gluten sheets

- Q: Is the quality of the resin wall the same?

- Of course there are differences, and there are several kinds of resin background walls.

- Q: What are the raw materials for composite manhole covers?

- Because the SMC polymer resin composite covers are made of resin and SMC polymer sheet pressing, without reinforcement than usual covers light weight 2/3, but this kind of SMC polymer resin composite covers and not because of its weight and reduce its carrying capacity, SMC polymer resin composite well cover bearing is three times that of ordinary resin composite manhole cover bearing, up to 90 tons

- Q: What is polymer composite cable trench cover plate?

- But on the actual sales market, the BMC material plus steel pressed into the cover plate, glass fiber reinforced plastic grille also become high polymer composite material cover plate.

- Q: Who knows what is the process flow of FRP splicing water tank?

- The SMC single board with stripping stroke is used for polishing and examining the single board. After checking, the single board is pressed in place and the installation hole is put in storage. Then, the single plate, the glue bar and the stainless steel bracket are combined to form a water tank.

- Q: Why is unsaturated polyester resin used in sheet molding? Why don't short fiber moulding plastics use unsaturated polyester resins?

- The requirement of BMC SMC process is that the material can be thickened, and the thickening properties of unsaturated resins are better

- Q: What is a sheet of material? Is it plastic? What is it used for?

- The sheet refers to the resin (or in the process of using monomer polymerization) as the main ingredient, such as plasticizers, fillers, lubricants, additives such as colorants as auxiliary components, can flow in the process of forming materials. In the material industry, SMC is commonly known as sheet material, and the full name of Chinese is: sheet molding plastics. The utility model relates to a premix for molding. In the glass fiber reinforced plastic industry, SMC is widely used. The large areas of sheet materials, such as automobile shell, water tank, seat and so on, are generally molded by SMC compression and heating.

- Q: What is the use of resin fiber powder extracted from the circuit board without breaking the law?

- Generally do not understand, go to Baidu Encyclopedia (don't waste your points) with molten glass made of very fine fiber, insulation, heat resistance, good corrosion resistance, high mechanical strength. Used as insulating material and as raw material for glass fiber reinforced plastics.

- Q: Composite manhole cover or cast iron well cover?

- Toward the color composite manhole cover is made of high temperature compression of SMC sheet, once formed, there is no recycling value, so it can be anti-theft

- Q: SMC sheet pressing out the product is not bright, what is the reason?

- This is mainly related to unsaturated polyester resins, and tree esters are classified into many grades

Send your message to us

SMC Sheet High Sound Absorption Material Rock Wool Blanket with Wire Mesh Water Repellent, Asbestos Free

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords