Lamina Geotextil Silt Fence / Woven Geotextile / Landscape with Green Line

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Landscape Fabric Description:

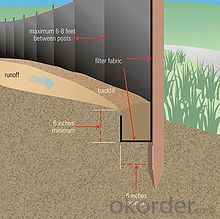

Landscape fabric, also referred to as a filter fence, is a structure composed primarily of geotechnical fabric and that is used as a form of sediment control.These temporary barriers are relatively low in cost, especially when compared to the damages they can prevent.

2. Landscape Fabric Functions and Features:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

3. Weed Barrier Fabric Applications:

1. Weed block for landscaped garden beds

2. Permeable liners for planters (stops soil erosion)

3. Weed control under wooden decking

4. Geotextile for separating aggregate / soils under walkway blocks or bricks

5. Assists in preventing paving from settling unevenly

6. Landscape fabric prevents soil erosion

3.. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: 300g / m2 geotextile permeability coefficient is generally how much?

- Geotextile cloth short fiber geotextile and long fiber geotextile, the two geotextile permeability coefficient is basically the same. According to the requirements of the national standard 300g / ㎡ geotextile permeability coefficient for the K * (10 negative side ~ 10 negative three power), K is between 1.0-9.9 values. From the indicators can be seen 300g / ㎡ specifications of the geotextile has a good water filter, can be used for water, filter them.

- Q: How do geotextiles help with subgrade stabilization?

- Geotextiles aid in subgrade stabilization by providing reinforcement and separation functions. They help distribute the load over a larger area, improving the subgrade's strength and load-bearing capacity. Additionally, they prevent intermixing of different soil layers, reducing the risk of differential settlement and improving overall stability.

- Q: How do geotextiles help in stabilizing embankments?

- Geotextiles provide essential reinforcement and stabilization to embankments by distributing loads, preventing soil erosion, and improving overall slope stability. They act as a physical barrier, effectively separating different soil layers and preventing them from mixing, which helps maintain the embankment's structural integrity. Additionally, geotextiles enhance drainage and filtration, allowing water to flow through while retaining soil particles, thus reducing pore water pressure and preventing saturation-induced failures. Overall, geotextiles play a vital role in enhancing the stability and longevity of embankments.

- Q: What are the applications of geotextiles in civil engineering?

- Geotextiles have a wide range of applications in civil engineering. They are commonly used in road construction, where they provide reinforcement and stabilization to the soil, preventing the formation of cracks and potholes. Geotextiles are also used in the construction of embankments and retaining walls, where they provide erosion control and improve soil stability. Additionally, they are used in drainage systems to filter out fine particles and prevent clogging. Overall, geotextiles play a crucial role in enhancing the performance and durability of various civil engineering structures.

- Q: Are high geotextiles harmful to people?

- High-tech geotextile is not harmful to people. High-iron geotextile for strong, tensile, anti-friction coefficient, anti-oxidation time and other indicators are very strict, it can be said that geotextile applications so far the highest requirements. The raw materials for the production of geotextile are polypropylene fiber, polypropylene fiber civilian use: can be pure or wool, cotton or viscose blended mixed woven to produce a variety of clothing. Can be used for weaving all kinds of knitwear such as socks, gloves, sweaters, knitted pants, dish cloth, mosquito cloth, was expo, warm filler, diaper wet. Industrial use: geotextile, industrial filter cloth, carpet, fishing nets, canvas, hose, concrete reinforced materials, industrial fabrics, nonwovens and so on. So do not worry, high-speed rail geotextile with environmental requirements, no harm to the human body.

- Q: Long-term exposure to geotextiles on the human body what harm?

- Geotextile material is mostly polyester, and the essence of polyester clothes the same. There are mineral water bottle material is also PET polyester polyester sheet. Polyester has been widely used in our lives, no radiation, no pollution, no poison. Long-term close contact with the geotextile on the body without injury. So you do not have to worry.

- Q: What is the difference between polypropylene geotextile, polypropylene geotextile and polyester geotextile

- Material is not the same

- Q: How are geotextiles used in geotechnical engineering?

- Geotextiles are used in geotechnical engineering to enhance soil stability, drainage, filtration, and erosion control. They are commonly used as reinforcement layers in road construction, embankments, retaining walls, and landfills. Geotextiles improve the overall performance and longevity of geotechnical structures by providing separation, filtration, and reinforcement functions.

- Q: What are the factors that affect the strength of geotextiles?

- The factors that affect the strength of geotextiles include the type and quality of the materials used in their production, the manufacturing process, the density and thickness of the fabric, the presence of any additional reinforcement layers, the level of UV stabilization, and the environmental conditions in which they are used.

- Q: What is the standard width of geotextile?

- Minimum width of 2 meters.

Send your message to us

Lamina Geotextil Silt Fence / Woven Geotextile / Landscape with Green Line

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords