SILICON METAL POWDER WITH LOW BORON

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

silicon metal supplier

1.Professional manufacturer

2.Controlled quality

3.Stable supply

4.Timely delivery

High Quality Silicon Metal Supplier

Description

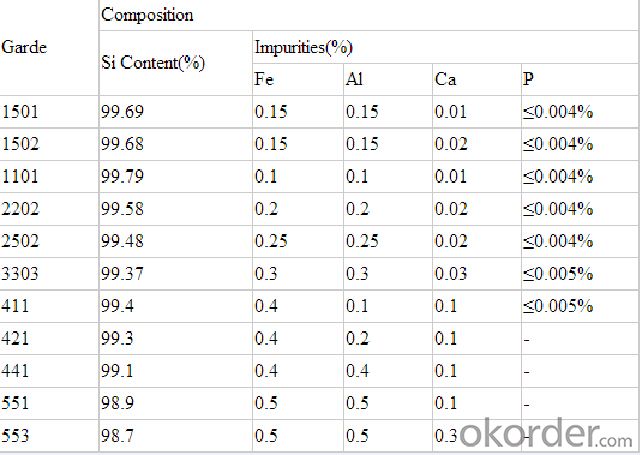

Silicon Metal processed by excellent industrial silicon and including full varieties. Used in electro, metallurgy and chemical industry. It is silver gray or dark gray powder with metallic luster, which be of high melting point, good heat resistance, high resistivity and superior oxidation resistance, it's called "industrial glutamate", which is an essential basic raw material in hi-tech industry.

Application

1) Widely applied to refractory material and power metallurgy industry to improve the heat resistance, wear resistance and oxidation resistance.

2) In the chemical line of organic silicon, industrial silicon powder is basic raw material that high polymer of organic silicon formatting.

3) Industrial silicon powder is sublimated into monocrystalline silicon, which is widely used in highttech field as an essential raw material for integrated circuit and electronic element.

4) In metallurgy and foundry line, industrial silicon powder is regarded as to be iron base alloy additive, the alloy pharmaceutical of silicon steel, thus improve the steel hardenability.

5) These are used in high-temperature material production in order to manufacture enamels and pottery. These also cater the demands of semiconductor industry by producing ultra-pure silicon wafers.

Size:10-100 mm, 3-10mm, 0-3mm or as customers’ requirements.

Packing: 25Kg/bag, 1MT/bag or as your requirements.

- Q: Carbide blade domestic that tricky point?

- China's carbide cutting tools must be the best cemented carbide in Zhuzhou.

- Q: What material is that ultrafine cemented carbide?

- You mean the ultra-fine grain cemented carbide, generally we have 0.6 alloy grain size is fine, which belongs to the tungsten carbide base hard alloy, ordinary tungsten carbide base hard alloy strength and hardness are higher than the same cobalt content. The process is mainly mixing, wetting, drying, forming, sintering, finishing, such as sand blasting, CVD/PVD coating, heat treatment, etc.

- Q: What kind of material is the alloy drill bit?

- Alloy bit generally refers to the hard alloy bit, divided into integral, welded, indexable inserts and replaceable type.The main components of cemented carbide are tungsten carbide, cobalt, etc., the hardness is relatively high, generally above HRC90 degrees, and it is suitable for batch processing and hard processing!

- Q: What kind of carbide alloy is used in stainless steel processing?

- Such as: YA6; YH1; YW3. This kind of steel has high hardness, small amount of feed to lower cutting speed, cutting the depth is bigger, avoid hardening layer on the surface of the skin with the previous procedure (Note 2).

- Q: Is Zhuzhou the largest cemented carbide producer in Asia?

- Of course, yes, or how could the 601 factory be so famous? That's the old military enterprise. It's the hard tool factory now. I hope it can help you!

- Q: How to tell what is hard alloy and what is high speed steel?

- Carbide is much more important than high speed steel.The proportion of cemented carbide is 14~15g/cm3, and the steel is only 8g/cm3

- Q: Carbide products which are used more?

- Sealing rings in the sealing industry, mould industry, machine tools, milling cutters, drill bits in the mining industry, and armor piercing shells in the army, etc.

- Q: How can I buy carbide die on the Internet? Who can help?!

- The mould made from the same carbide alloy made from Zhuzhou will not be sold.

- Q: What are the types of cemented carbides?

- 5, industry special cutter category, including auto industry special knife, mobilization machine, industry special knife, sewing machine industry special knife, die industry special knife, textile machine special knife and printed circuit board industry special knife.Hard alloy tool with cemented carbide and carbon steel bar welded, it is characterized with high hardness, wear resistance and heat resistance of hard alloy blades are made of high abrasion resistance and high heat resistance WC (tungsten carbide), TiC (Tan Huatai), TaC (TAC) and Co (cobalt) powder after high temperature sintering.Different cemented carbide is suitable for different purposes, so you can refer to the following, I hope you can help!

- Q: Where can I use cemented carbide?

- Modern ultra hard alloys are produced by sintering of carbides of tungsten carbide and some other elements. It is the hard metal (tungsten, tantalum, titanium, molybdenum, etc.) carbide carbide particles, with one or several iron elements (cobalt, nickel or iron) powder mixed, pressed molding, and then made by sintering.Cemented carbide is the most powerful alloy in the world at present. Hard alloy widely used now has two main categories: the first is to do the cobalt WC alloy binder; the second is to make titanium carbide alloy tool steel binder.Cemented carbide is used as a tool, and its hardness will not decrease even at high temperatures of 1000 degrees. Therefore, for high speed cutting, cutting speed up to 2000 meters per minute, 100 times higher than the ordinary carbon steel cutter, tungsten steel cutter is 15 times higher than. The mold made of it can be punched about 3000000 times, which is 60 times longer than the ordinary alloy steel die.

Send your message to us

SILICON METAL POWDER WITH LOW BORON

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords