Raw Materials for Refractory - Silicon Carbide/SiC for Chemical Industry (Abrasive and Refractory Materials)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon Carbide/SiC for Chemical Industry(Abrasive and refractory materials)

1.Structure of Silicon Carbide Description

Black Silicon Carbide is produced with high temperature in a electric resistant furnace from a mixture of quartz sand and petroleum coke.

Black silicon carbide is typically used for working on cast iron ,non-ferrous metals, stone, leather, rubber, and other materials which requires sharp cutting characteristics. The mineral is also used widely as a refractory material and metallurgical additive.

2.Main Features of the Calcined Bauxite

Its hardness is between that of fused alumina and synthetic diamond and mechancial intensity of it is also greater than that of fused alumina. It is brittle and very sharp and has a certain degree of electrical and heat conductivity.

3.Main usage of the Calcined Bauxite

1.Grinding non-ferrous materials, rock, stone, leather, rubber, finishing tough and hard materials

2.Bonded abrasive tools, lapping and polishing

3.Widely used as a metallurgical additive and refractory material

4.Refractory

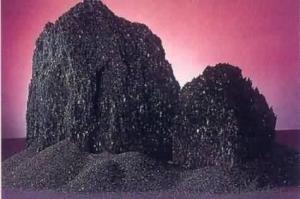

4. Calcined Bauxite Images

5. Calcined Bauxite Specification

Grit Size | SiC | FC | Fe2O3 |

F12-F90 | 98.50 | <0.20 | 0.60 |

F100-F150 | 98.50 | <0.30 | 0.80 |

F180-F220 | 97.00 | <0.30 | 1.20 |

F230-F400 | 96.00 | <0.40 | 1.20 |

F500-F800 | 95.00 | <0.40 | 1.20 |

F1000-F1200 | 93.00 | <0.50 | 1.20 |

P12-P90 | 98.50 | <0.20 | 0.60 |

P100-P150 | 98.00 | <0.30 | 0.80 |

P180-P220 | 97.00 | <0.30 | 1.20 |

P230-P500 | 96.00 | <0.40 | 1.20 |

P600-P1500 | 95.00 | <0.40 | 1.20 |

P2000-P2500 | 93.00 | <0.50 | 1.20 |

6.FAQ of Calcined Bauxite

1). Q: Are you a factory or trading company?

A: We are a factory.

2). Q: Where is your factory located? How can I visit there?

A: Our factory is located in Ningxia, China. You are warmly welcomed to visit us!

3). Q: How can I get some samples?

A: Please contact me for samples

- Q: The fire prevention board line is made of what material?

- Crural line: wooden, in the market, there are sjoiner woodblock, peach wood and artificial engraving. The second classification is stone and the most used one is the marble graved or ceramics well-made one is taken as the first choise. Its price is a little bit expensive than the wooden one, but also a suitable choise. Condole supports: It has various category. The general furniture choose plaster and anti-firing plate and the other also have a choice of steel. You can make a suitable choice according to the need. If it is contracting project, it depends on your project specific plan and funds plan. In a word, beauty and harmony should be given priority since it is the source of design.

- Q: How to understand qualitative and qualitative refractory materials?

- Such as amorphous refractory castable, referred to as bulk loading, cast material, ramming material, refractory clay etc., utensils and other special products. Amorphous refractory material products, refractory heat insulating bricks and experimental and industrial crucible, spraying materials, such as burning bricks, electric melting brick, turn it into required shape and process heat treatment in where it is used.

- Q: How can refractory material of the electric furnace be used for longer.

- Minimize mechanical shock, Electrical furnace commonly referred to must be electrical arc furance. The wall of electric arc furnace should be constrcuted with magnesite carbon brick. Its hearth permanent layer should be constrcuted with mansornary magnesia brick. High alumina brick is usually used to aviod furnace cover suddenly get hot and cold. But its service life is lower. At present integral casting furnace cover is made of alumina magnesia. Terminal will be created even without the use of refractory material. Consumption is much faster if using refractories material or whole knottiing mainly.

- Q: How to detect the acid resistance of refractory? Is there any standard? Thank you

- Setting the acid resistancere of fractory products is simple; R22, two measurement methods are both bricking refractory products, using the mass fraction of the original dry to indicate. It is generally select vitriol as the medium of erosion, such as the international standard determination of the resistance to sulfate of dense shaped refractory products "(ISO8890) and PRE /, grinding fine particles to 0.63 ~ 0.80 mm, and then measure its quality loss, put it in the vitriol with mass fraction of 70%, finally boil 6 h.

- Q: What is molten silicon? What refractoriness do refractories made by it have? What properties of using does it have?

- Molten silicon can be called quartz glass, which shows an amorphous silicon state. It is a liquid fusion at above 1723 degree and is an ultra-cooling state at low temperatures. It is not generated in refractories, but generated in the matrix, showing liquid state at a high temperature capable of buffering the stress with somewhat binding properties. If quartz glass is used as refractory, its function are melrly these ones. (These are what I konw for reference only.)

- Q: who knows the requirements of refractory for forge furnace?

- Forging heating furnace working temperatures above 1000 ° C, reasonably choosing refractory for build furnace has an important meaning for guaranteeing the normal operation of the heating furnace, improving the service life of furnace and energy saving. refractory is generally required to have the following properities: 1, it should be equipped with the properity of no deformation and melting under certain temperature. 2, it should be equipped with the neccessary structural strength without softening deformation in high temperature. 3, volume stability at high temperature, brick body won't be deformation or cracked due to expansion and contraction; 4, not broken and peel off under rapid changes of temperature or uneven heating; 5, resistant to chemical erosion of molten metal, slag and furnace gas,etc.

- Q: Where is the sizing nozzle for refractories? Just enter the line, master into!

- Refractories in this industry, Luoyang Hua Heng is the first to bear, and their services are thoughtful, and the quality is still very good!Wish you success!

- Q: The difference between refractory and thermal insulation material

- In simple terms, refractoriness is different. The refractoriness of refractory is high while that of insulation material is low.

- Q: What are the raw materials of refractory?

- Of course, different types have different raw materials: Magnesite (the electric?smelting: alkaline refractory, magnesia-carbon bricks, alkaline, high-purity) + crystalline flake graphite + phenolic resin + additive (silicon powder, aluminite powder, silicon carbide powder, or high-temperature asphalt,etc.) , acidic refractory: The neutral is not easy to answer. such as. You can check out the classification, such as

- Q: Fire insulation and fireproof insulation board materials What is the difference in performance?

- Fireproof materials and insulation materials, refractories not the same thing, but some insulation materials are fire resistant and refractory. Fireproof material is a synthetic material characteristics of fire resistance or the material itself is a high temperature resistant, flame-retardant. Fireproof materials are mostly used for construction, playing an important role in fireproof today in various forms.

Send your message to us

Raw Materials for Refractory - Silicon Carbide/SiC for Chemical Industry (Abrasive and Refractory Materials)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords