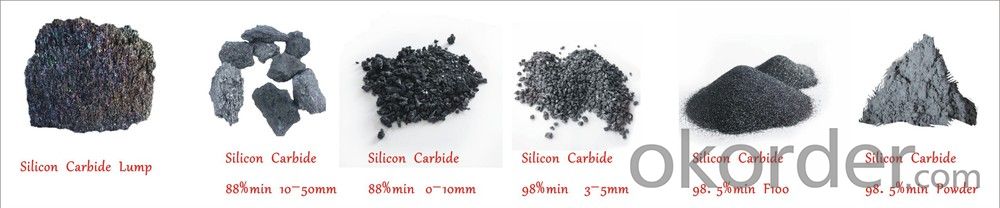

Raw Materials for Refractory:Silicon Carbide 88% 90% 0-10mm Metallurgical Grade Silicon Carbide

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Brand Name: | cnbm | Model Number: | LF-SIC |

| Material: | SiC | Usage: | Abrasives, Advanced Ceramics, Refracotry, Metallurgical | Abrasive Grain Sizes: | Powder, Grain, Lump |

| Name: | Silicon Carbide | Sample: | For Freight | SiC content: | 85% 88% 90% 98.5% 99% |

| MSDS: | Available | DGM: | Available | Bulk Density: | 1.38-1.70 g/cm3 |

| Grain Size: | F12-F8000 JIS standard, 0-1,1-10,0-10mm | Moh's Hardness: | 9.5 | Original: | Henan, China (mainland) |

Packaging & Delivery

| Packaging Details: | Silicon Carbide Powder:25kg pp bags loaded in 1 ton jumbo bags Silicon Carbide Lump: 1 ton loose in Jumbo bags. Or as customer request. |

| Delivery Detail: | 7 days after payment |

silicon carbide and green silicon carbide

Silicon Carbide

Product Description

Black Silicon Carbide is made by a precision water classification process and air flow classification using material that is produced from the reaction between high purity silica sand and petroleum coke in a resistance-type furnace. Measuring 9.0+ on the MOHS scale of hardness, silicon carbide is one of the hardest abrasives known in the industry. The inherent friability of the sharp crystalline structure assures the continuous exposure of new cutting edges, which produces a faster and cleaner cutting performance.

Our silicon carbide grains and powders can be made to your exact size, chemistry and shape specifications.

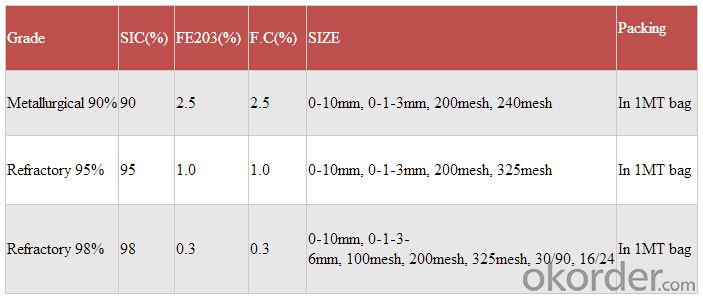

Metallurgical and Refractory Grade

Content of SiO2 | Particle Size Distribution | F.C % | Fe2O3 % | H2O % |

88% | Lump | 3 max. | 2.8 max. | 1 max. |

0-10 | 2.8 max. | |||

0-1 | 3 max. | |||

1-3 | ||||

3-6 | ||||

100F | 2.8 max. | 2.8 max. | ||

200F | 2.8 max. | 2.8 max. | ||

240F | 3 max. | 3 max. | ||

325F |

- Q: What kinds of fireproof and fire retardant materials are there?

- What kinds of fireproof and fire retardant materials are there? What is the criteria for making fireproof and fire retardant materials?

- Q: How to distinguish the construction fire-proof material rating?

- Each country has its own fireproof standards, so I do not know which country you are in ? Each country has different division levels of fireproof materials, such as GB 8624, German standard DIN 4102-1, British standard BS 476, France standard NF P92-501 and so on. GB 8624 Chinese building materials and products combustion performance division levels fireproof resources network (FireTC.

- Q: What are the standards of refractory concrete ?

- It can be divided into: 1. Ordinary refractory concrete Aggregates used include high alumina, clay, silica, basic materials (magnesite, chromite, dolomite, etc.) or special materials (carbon, silicon carbide, zircon, etc.). It can also use several combination of refractory material. 1. Thermal insulated refractory concrete It is mainly formulated with refractory light aggregates. The light aggregate used can be expanded perlite, vermiculite, ceramsite, porous chamotte, alumina hollow ball, etc. It can also be a combination of several refractory light aggregates or combination of the refractory aggregates. The aggluetination material used in refractory concrete can be high alumina cement, phosphate binders, water glass binder and clay, etc.

- Q: What's the requirements of fire-fighting criteria of heat insulating material?

- It shouldn't be under than B2 level. Roofing insulation fire rating requirements: the ministry of public security, housing and urban-rural development department issued about printing and distributing the civil building external thermal insulation system and the interim provisions on the exterior wall decorative fireproof prescribed in the notice: roof grassroots adopted duration of fire resistance is the non-combustible component that shouldn't less than 1.00 h's. Its roof insulation materials should not be below B2; Otherwise, the combustion performance of insulating material should not be below the B1 level. The junction of the roof and wall, the insulation layer around the opening part of roof should use the grade A thermal insulation material to set level fire-fighting belt that width is not less than 500 mm.

- Q: I want to consult the fire resistant level standards of external wall thermal insulation materials.

- Fire resistant level standards of external wall thermal insulation materials: 1, The thermal insulation material that has A-class combustion performance: Spraying inorganic fiber, glass wool, foam glass, ceramic foam, rock wool, foam cement and perlite obturator, and so on. 2, The thermal insulation material that has B1 level combustion performance: Special processed extruded polystyrene board (XPS) / special processed polyurethane (PU), phenolic and polystyrene powder. 3, Thermal insulation materials that have level B2 combustion performance: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

- Q: What are the qualifications of refractory industry?

- Certificate for production and sale is needed, just like the certificate for other products.

- Q: What is molten silicon? What refractoriness do refractories made by it have? What properties of using does it have?

- Molten silicon can be called quartz glass, which shows an amorphous silicon state. It is a liquid fusion at above 1723 degree and is an ultra-cooling state at low temperatures. It is not generated in refractories, but generated in the matrix, showing liquid state at a high temperature capable of buffering the stress with somewhat binding properties. If quartz glass is used as refractory, its function are melrly these ones. (These are what I konw for reference only.)

- Q: How long is the fire resistance time of the AAAfire resistance rolling shutter door?

- How long is the fire resistance time of the AAA fire resistance rolling shutter door?

- Q: What refractories can withstand high temperature above 2100 degrees?

- You can refer to advices from the first one coupled with the second one.

- Q: What are the differences of ceramics and refractories? Is the ceramics belonging to refractories?

- No In the high school chemistry, the former is talking about the traditional inorganic material, the latter is belonged to the new materials.

Send your message to us

Raw Materials for Refractory:Silicon Carbide 88% 90% 0-10mm Metallurgical Grade Silicon Carbide

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords