Silicon Carbide 88% 90% 0-10mm Metalllurgical Grade Silicon Carbide

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Silicon Carbide Description

Silicon Carbide is made by a precision water classification process and air flow classification using material that is produced from the reaction between high purity silica sand and petroleum coke in a resistance-type furnace. Measuring 9.0+ on the MOHS scale of hardness, silicon carbide is one of the hardest abrasives known in the industry. The inherent friability of the sharp crystalline structure assures the continuous exposure of new cutting edges, which produces a faster and cleaner cutting performance.Silicon Carbide powders are precisely graded to the particle size specifications set forth by the European FEPA “F” Microgrit Standard.Silicon Carbide powders are also available in sizes that are graded to the “JIS” Japanese Industrial Standard. Material is available in both Black and Green color.

2.Main Features of the Silicon Carbide

It is produced in a high temperature electric resistance-type furnace from a mixture of quartz sand and petroleum coke. The hardness of black silicon carbide is greater than fused alumina but less than synthetic diamond. Its mechancial intensity is greater than fused alumina, but is brittle and very sharp. The mineral has some electrical and heat conductivity. Black silicon carbide is typically used for machining or finishing cast iron ,non-ferrous metals, stone, leather, rubber, and other materials where sharp cutting characteristics are important. The mineral is also used widely as a refractory material or metallurgical additive. More detailed specifications can be supplied on your request.

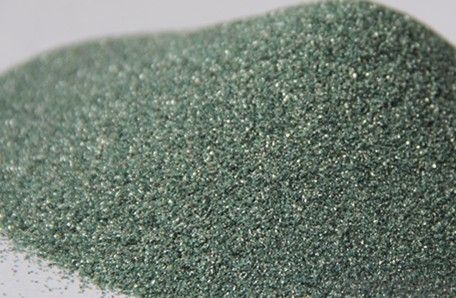

3. Silicon Carbide Images

4. Silicon Carbide Specification

| Place of Origin: | Henan, China (Mainland) | Brand Name: | CNBM | Model Number: | LF-SIC |

| Material: | SiC | Usage: | Abrasives, Advanced Ceramics, Refracotry, Metallurgical | Abrasive Grain Sizes: | Powder, Grain, Lump |

| Name: | Silicon Carbide | Sample: | For Freight | SiC content: | 85% 88% 90% 98.5% 99% |

| MSDS: | Available | DGM: | Available | Bulk Density: | 1.38-1.70 g/cm3 |

| Grain Size: | F12-F8000 JIS standard, 0-1,1-10,0-10mm | Moh's Hardness: | 9.5 | Original: | Henan, China (mainland) |

5.FAQ of Silicon Carbide

1). Q: Are you a factory or trading company?

A: We are a factory.

2). Q: Where is your factory located? How can I visit there?

A: Our factory is located in ShanXi, HeNan, China. You are warmly welcomed to visit us!

3). Q: How can I get some samples?

A: Please connect me for samples

4). Q: Can the price be cheaper?

A: Of course, you will be offered a good discount for big amount.

Send your message to us

Silicon Carbide 88% 90% 0-10mm Metalllurgical Grade Silicon Carbide

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches