Calcium Silicate Bricks Size for Coke Oven and Hot Blast Stove Refractory Bricks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silica bricks for hot stoves feature sharp dimension,low expansion,little residual quartz, low true density.low creep rate,good thermal shock resistance upon 600°C. It mainly used at high temperature area include arch and upside of hot stove and upside of checker.

Andalusite bricks are mainly used in the cooling wall of blast furnace, chemical and ceramic industry, the door of coke oven, or as the lining and checker of hot blast furnaces.

Silica bricks exhibit excellent refractoriness. These bricks performs extremely well under consistently high temperature.

Application:

1 Building materials for steel making furnace

2 Kiln car building

3 For glass furnace

Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

Typical features:

Widely used in coke ovens.

Used in high temperature sections of the checker chamber in hot blast stoves.

Used as low-cost alternative to andalusite and mullite checker bricks in hot blast stoves.

High refractoriness, average thermal shock resistance make it suitable in consistant temperature environment.

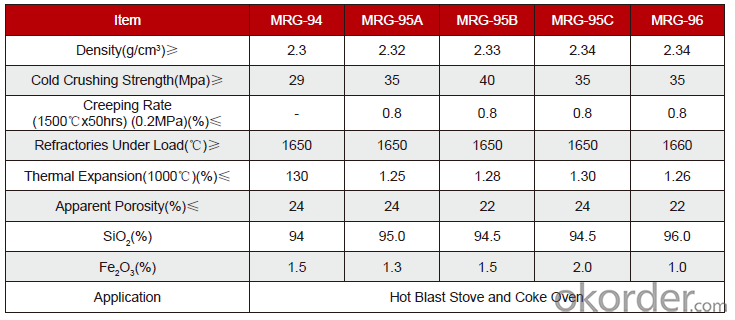

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The use of high thermal conductivity of silica brick, reducing coke fuel consumption, reduce emissions of pollutants such as NOx, with considerable economic benefits and social benefits, is the future direction of the new technology of using coke oven refractory.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into phosphorus and quartz. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick with silicon oxide content, low melt index, mainly used for glass kiln crown, parapet, wall hanging, small furnace arch superstructure and regenerator.

- Q: Which material is good for furnace refractory?

- Basic refractories in Magnesium Oxide and calcium oxide as the main ingredient, commonly used is brick. Magnesium Oxide 80% to more than 85% containing magnesia brick, has good resistance to alkaline slag and slag, refractory clay brick and brick high ratio. Mainly used in open hearth furnace, oxygen converter, electric furnace, non-ferrous metal smelting equipment and high temperature equipment.

- Q: The brick is mainly used in the place?

- Open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts.

- Q: Why is the three oxidation of two silicon is very harmful impurities in silica brick

- Heating calcination is the best way to extend this sort of impurity removal. Remove impurities

- Q: What are the main constituents of refractory bricks?

- (a) containing refractory brick brick, refers to more than SiO293%, is the main varieties of acid resistant brick. It is mainly used for coke oven building, also used in furnaces all kinds of glass, ceramic and carbon calciner, refractory brick arches and other load-bearing parts, is also used in high temperature bearing part of hot blast stove, but should not be used in thermal equipment below 600 DEG C and the temperature fluctuation in the.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: Why in the production of the brick to detect the volume density

- Fast density test, please consult an instrument.

- Q: Physical solid waste disposal

- The amount of addition is related to the shape and weight of the brick. The bricks can be added to 20% weight less than 25kg; bricks above 25kg can be added to 30%; for the specific type of brick can be added 30%. into waste silica brick should pay attention to this problem

Send your message to us

Calcium Silicate Bricks Size for Coke Oven and Hot Blast Stove Refractory Bricks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords