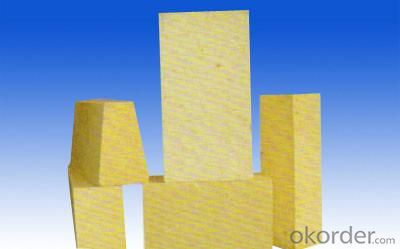

Silica Brick - Lightweight

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 50000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden pallet |

| Delivery Detail: | 20days after receiving the advance |

Specifications

Light Weight Silica Brick

1. High refractoriness

2.High porosity

3.Good thermal shock stability

4.Best price, high quality

Brief description

1. High refractoriness

2.high porosity

3.good thermal shock stability

Main Technical Property Indexes

Item | |

SiO2≥ | 91 |

Refractoriness℃ | 1670 |

RUL(0.2MPa)0.2MPa℃ | 1560 |

Apparent Porosity%≤ | 45 |

CCS Mpa≥ | 3.5 |

Density g/cm3≤ | 1.2 |

Typical Application

Lightweight silica brick is mainly used for thermal insulation or reduce weight without direct contact with molten material, gas is not subject to erosion, don't suffer from temperature leaps kiln parts. Use at high temperatures, can not contact with alkaline refractory materials. According to the material is qualitative different, its highest use temperature at 1200 ~ 1550 ℃.

Advantage of Light Weight Silica Brick

Lightweight silica brick is lightweight refractory with silicon dioxide more than 91%, the volume density of 1.2 g/cm3 .Refractoriness and refractoriness under load and the composition of the same common silica brick. But due to the porosity, so the compression strength and slag resistance, corrosion resistance and other than ordinary silica brick, and thermal shock resistance is improved.

- Q: The introduction of silica brick

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature.

- Q: Physical solid waste disposal

- The production of silicon material is added to the cause of waste brick:Preparation of silica brick pug, a certain amount of waste silica brick used to add ingredients, for the purpose of expansion and stress reduction products during firing

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- Classification of chemical components of refractory materialsAccording to the chemical characteristics of refractory raw materials can be divided into acidic refractory materials, such as silica, zircon etc.; neutral refractory raw material, such as corundum, bauxite, mullite (acidic) (acidic), Ge (alkaline) iron and graphite; alkaline refractory materials, such as magnesite, dolomite, magnesium sand calcium sand.

- Q: The specific content is what gb/t2608-2012 brick

- The provisions of the brick classification, technical requirements, test methods,

- Q: The introduction of silica brick

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: How much is the highest melting point of silicon?

- Acidic silica brick refractories, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature. More than 94% silica content.

- Q: What role does silica play in refractories?

- The natural mineral of silica is called quartz. In refractories, silica and siliceous refractory materials contain more silica. Silica is acidic at high temperature, and siliceous refractory can resist acid slag corrosion

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- That is because the brick load softening point the maximum temperature is 1450 degrees.

- Q: Why in the production of the brick to detect the volume density

- Product quality control of silica brick.

- Q: Physical solid waste disposal

- Preparation of silica brick pug, a certain amount of waste silica brick used to add ingredients, for the purpose of expansion and stress reduction products when firing, reduce cracks, improve the rate of finished products.

Send your message to us

Silica Brick - Lightweight

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 50000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords