Silica Brick - Superior Quality Silica Lightweight Silica Brick for Melting Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silica bricks for hot stoves feature sharp dimension,low expansion,little residual quartz, low true density.low creep rate,good thermal shock resistance upon 600°C. It mainly used at high temperature area include arch and upside of hot stove and upside of checker.

Andalusite bricks are mainly used in the cooling wall of blast furnace, chemical and ceramic industry, the door of coke oven, or as the lining and checker of hot blast furnaces.

Application:

1 Building materials for steel making furnace

2 Kiln car building

3 For glass furnace

Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

Typical features:

1 Excellent thermal stability

2 High refractoriness under load

3 Chemical stability and anti-corrision

4 Small high temperature creep rate

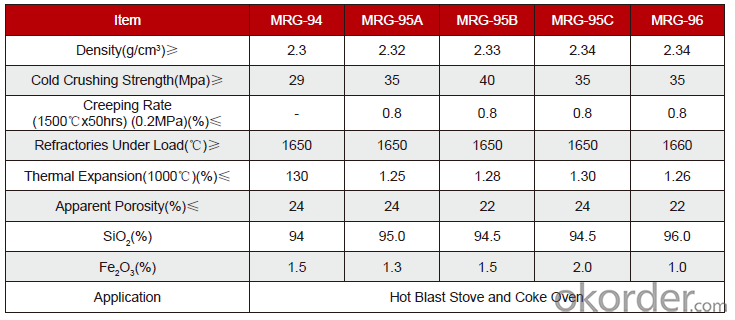

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- Acidic materialMainly siliceous materials, such as quartz, tridymite and cristobalite, chalcedony, flint, opal, white quartzite, silica sand, diatomaceous earth, silicon oxide contained in these siliceous materials (SiO2) at least 90%, pure raw materials are silicon oxide as high as 99% or more. Siliceous materials at high temperature is the acidic nature of chemical dynamics, when the presence of metal oxide, or when in contact with the chemical reaction, and combined with a fusible silicate. Therefore, if there is a small amount of metal oxide in siliceous material, it will seriously affect its thermal resistance.

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- How to keep the brick masonry temperature not lower than 600 DEG C, while the exhaust temperature is not higher than 400 DEG C.

- Q: Common bond brick?

- Lime should contain a lot of active CaO, I decompose CaCO3 and MgCO3 not more than 5%, Al2O3+Fe2O3+SiO2 no more than 5%. When the content of large particles, burned Ca-CO3 and over burned lime, the product produced caves, affecting the quality of products.

- Q: Why will expand when heated brick

- In the process of SiO2 drying, the four crystalline transformation points of 117, 163, 180~270 and 573 DEG C are found, among which the volume expansion caused by the 180~270 is the largest.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- This is a kind of refractory material is divided into three types: semisilica brick (A12O315 ~ 30%), clay brick (A12O330 ~ 48%), high aluminum brick (A12O3>48%).

- Q: Can iron oxide be used as refractory material?

- Iron oxide can not be used as refractory material, but it can be used as refractory additive. Iron oxide can be used as pigment

- Q: Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q: Common bond brick?

- Lime should contain a lot of active CaO, I decompose CaCO3 and MgCO3 not more than 5%, Al2O3+Fe2O3+SiO2 no more than 5%. When the content of large particles, burned Ca-CO3 and over burned lime, the product produced caves, affecting the quality of products.

- Q: How to improve the thermal conductivity of the coke silicabrick rate?

- To improve the thermal conductivity of silica brick for coke oven rate method:Manufacture of high density and high thermal conductivity of silica brick, adding additives such as CuO, Cu2O, TiO2, Fe2O3, (FeO), can improve the thermal conductivity of silica brick.

Send your message to us

Silica Brick - Superior Quality Silica Lightweight Silica Brick for Melting Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches