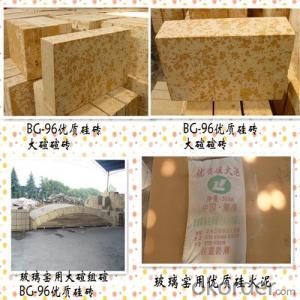

Silica Brick - Fused Silica Refractory Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Good acid and erosion resistance;

2.Widely used for different furnace;

3.Good bonding and structural strength of furnace.

Features:

1.Good acid and erosion resistance, powerful anti high-temperature strength.

2.Soften melting temperature is 1620~1670 °C.

3.Low thermal shock resistance.

4.Natural silica as raw material, plus regular mineralizer.

5.Ensure good bonding and structural strength of furnace.

6.Good heat resistance and long service life.

Application:

1.Glass melting furnace, ceramic frit kiln, sodium silicate furnace, soaking furnace, ceramic kiln, etc

2.Coke oven's coking chamber, combustion chamber walls, steel open-hearth's regenerator and sediment chamber, etc.

3.Load-bearing parts of high temperature hot air furnace and acid open-hearth furnace roof, etc.

Item | Properties | |||

BG-96A | BG-96B | BG-95A | BG-95B | |

SiO2,% | 96 | 96 | 95 | 95 |

Fe2O3 ,% | 0.8 | 1.0 | 1.2 | 1.2 |

Melt index,% Unit weight<20KG Unit weight≥20KG |

0.5 0.6 |

— — |

0.7 0.7 |

— — |

Cold Crushing strength MPa, Unit weight<2KG Unit weight≥20KG |

35(30) 30(25) | |||

Softening temperature under load,°C | 1680 | 1670 | 1660 | 1650 |

Apparent porosity % | 22(24) | |||

Bulk density,g/cm3 | 1.85-1.9 | |||

True density,g/cm3 | 2.34 | 2.35 | ||

Application | sodium silicate furnace,ceramic frit furnace ,glass furnace,coking furnace, metallurgical furnace and other furnaces | |||

- Q: The specific content is what gb/t2608-2012 brick

- The provisions of the brick classification, technical requirements, test methods,

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into phosphorus and quartz. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick with silicon oxide content, low melt index, mainly used for glass kiln crown, parapet, wall hanging, small furnace arch superstructure and regenerator.

- Q: Which material is good for furnace refractory?

- Kiln types of refractories is very extensive, selection of refractory materials according to the type of furnace furnace temperature and use of selected refractory material, refractory material is divided into custom products of refractory bricks and unshaped refractory castable series products. According to chemistry, it is divided into acidic, neutral and alkaline materials.

- Q: Can not use it two brick

- The softening temperature is up to 1640~1670 DEG C, and the volume is stable at high temperature for a long time.

- Q: Common bond brick?

- Lime should contain a lot of active CaO, I decompose CaCO3 and MgCO3 not more than 5%, Al2O3+Fe2O3+SiO2 no more than 5%. When the content of large particles, burned Ca-CO3 and over burned lime, the product produced caves, affecting the quality of products.

- Q: How to improve the thermal conductivity of the coke silicabrick rate?

- To improve the thermal conductivity of silica brick for coke oven rate method:Manufacture of high density and high thermal conductivity of silica brick, adding additives such as CuO, Cu2O, TiO2, Fe2O3, (FeO), can improve the thermal conductivity of silica brick.

- Q: The chemical composition of silica brick and its physicochemical index?

- The physicochemical index of silica brick:Turn left to |

- Q: The formula in the refractory brick, and firing curve, who knows?

- Iron scale powder 0.45-0.55%, cement 0.9-1.1%, lime milk 6.5-7.5%, pulp 1.95-2.2%, the silica powder, perlite will be added to the wet mill in proportion, and then add iron scale powder, cement, dry roller 1-2 minutes later

- Q: Such purpose and scope please give me detailed points thank you

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

Send your message to us

Silica Brick - Fused Silica Refractory Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords