Silica Brick G95B for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

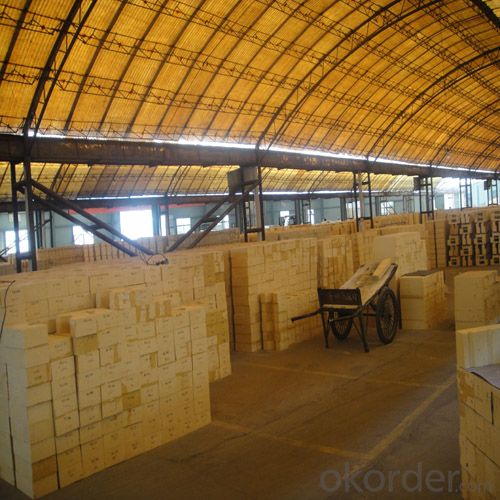

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

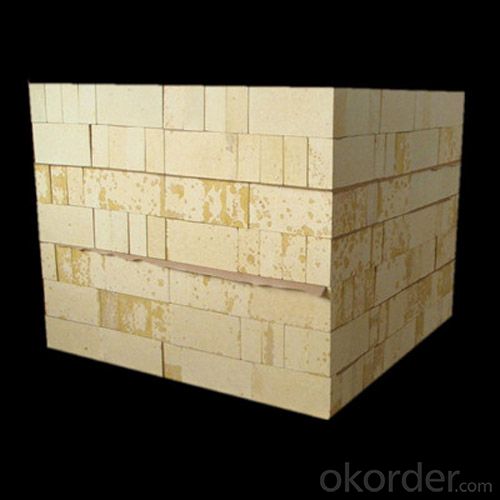

General Information of SilicaBrick For Coke Oven

Our corporation produces a comprehensive range of silicabricks, with high silica content, all of these bricks exhibit excellentperformance.

Our Silica bricks are the final result of blendingexcellent tridymite and cristobalite, as the main raw materials withcutting-edge technology, after mixing, drying, forming, in the high temperatureshuttle kiln. There are also little quartz and vitreous within. We ensure youthat the silica bricks made by us possess high quality standard and have gonethrough all the complicated quality control parameters. Their durability andstrength adds life to the structure and they have the capacity of bearing hightemperature.

Feature of Silica Brick For Coke Oven

Resistant to thermal shock, abrasion, chemical attack

High ability for anti-abrasion during work

Superior resistance to acids (including oxidizing)

Resistance to chlorine

Resistance to thermal shock and pressure changes

Low thermal and chemical expansion

Applications of Silica Brick Coke Oven

Silica brick for Coke Oven ismainly used in Coke Oven.

Physical Properties: |

|

|

Permanent Linear Change(1500℃×4h)% | % | ±0.2 |

Apparent Porosity, % | % | |

Cold Crushing Strength | Mpa | 29.4 |

Refractoriness Under Load (T0.6) | ℃ | ≥1600 |

Thermal Expansion | % | ≤1.3 |

Density | g/cm3 | ≥2.35 |

Chemical Analysis: |

|

|

SiO2 | % | ≥95 |

Fe2O3 | % | ≤0.5 |

Al2O3 | % | ≤0.8 |

Residual Quartz | % | ≤1 |

Note: | ||

- Q: Why will expand when heated brick

- After high temperature after the formation of tridymite and cristobalite and quartz and a small amount of residual glass phase, quartz heating to 220-240 DEG C, in a certain degree of thermal expansion, brick maximum expansion occurs in 100~300 DEG C, 300 expansion before the total amount of expansion is about 70%~75%.

- Q: Such purpose and scope please give me detailed points thank you because I am learning stage

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- This is a kind of refractory material is divided into three types: semisilica brick (A12O315 ~ 30%), clay brick (A12O330 ~ 48%), high aluminum brick (A12O3>48%).

- Q: Which material is good for furnace refractory?

- Acid refractory with silicon oxide as the main component, are commonly used in brick and clay brick. Silica is silica containing more than 94% silica products, raw materials used in silica, silica and other waste, the acid resistance of slag erosion ability, high load softening temperature, volume shrinkage after repeated burning, or even a slight expansion; but it is vulnerable to the erosion of basic slag, thermal shock resistance is poor. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Clay brick with refractory clay as the main raw material, containing 30% to 46% of alumina, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used.

- Q: The United States of our brick anti-dumping duties?

- . According to the relevant legal procedures, the United States International Trade Commission will make a final ruling on the anti dumping industrial injury before January 6, 2014, if an affirmative determination, the U.S. Department of Commerce will be involved in product release tax anti-dumping order.

- Q: Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q: Brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass. Tridymite and cristobalite and quartz remaining at low temperature due to phase change, volume changes greatly, so the brick thermal stability at low temperature is very poor. In use, under 800 degrees Celsius, slowly heating and cooling, so as not to produce cracks. The use of temperature in blast furnace so should not be below 800 DEG on.

- Q: The chemical composition of silica brick and its physicochemical index?

- ????Al2O3 SiO2??????fe2o3??????cao???????r2o93~98?0.5~2.5?;;?0.3~2.5??0.2~2.7;??1~1.5;

- Q: What is the silica refractory products?

- Refractory brick with silica content greater than 90%.

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

Send your message to us

Silica Brick G95B for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords