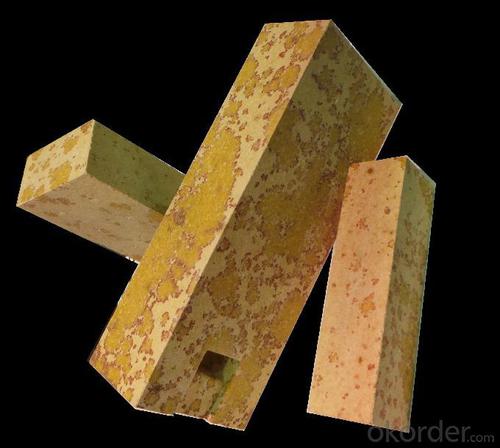

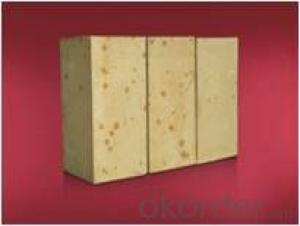

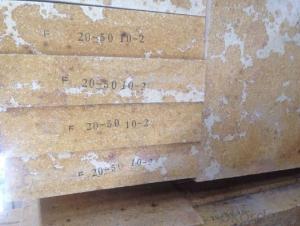

Silica Brick for Glass Furnace G-97A

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX silica brick using high quality silica as raw material to ensure superior performance of silica bricks, the raw materials is high quality dinas rock with SiO2 of 99% min. Its unique structure helps ease forming. Moreover, advantages of complete transformation after sintering and lower residual quartz enable to produce super-duty silica bricks.

Performance:

The silica bricks for glass furnace is characterized by high purity, less impurity, good corrosion resistance, higher bulk density, complete phase transformation, lower residual quartz, high RUL, lower thermal expansion and stable volume at high temperature. This leads to increase in service life of glass furnace and reduction in energy consumption. These products have found wide application in crown and key areas and been highly appreciated by clients.

Application

CMAX Silica bricks are commonly applied in

Coke oven

Hot blast stoves

Glass furnace

Technical Data

ITEM | For Hot-Blast Stoves | For Glass Furnace | ||||||

S-94 | S-95 | S-95B | G-94 | G-95A | G-95B | G-96A | G-96B | |

SiO2, % | ≥ 94 | ≥ 95 | ≥ 95 | ≥ 94 | ≥ 95 | ≥ 95 | ≥ 96 | ≥ 96 |

Fe2O3, % | ≤ 1.5 | ≤ 0.5 | ≤ 1 | ≤ 1.5 | ≤ 1.2 | ≤ 1.2 | ≤ 0.8 | ≤ 1 |

Residual Quartz, % | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 | ||||

Apparent Porosity | ≤ 23 | ≤ 23(24) | ≤ 21(23) | ≤ 24 | ≤ 22(24) | ≤ 22(24) | ≤ 22(24) | ≤ 22(24) |

True Density, g/cm 3 | ≤ 2.35 | ≤ 2.34 | ≤ 2.33 | ≤ 2.35 | ≤ 2.35 | ≤ 2.34 | ≤ 2.34 | |

Cold Crushing Strength, Mpa | ≥ 29.4 | ≥ 30(27) | ≥ 30(20) | ≥ 30 | ≥ 30(35) | ≥ 30(35) | ≥ 30(35) | ≥ 30(35) |

Refractoriness Under Load, º C | ≥ 1650 | ≥ 1600 | ≥ 1630 | ≥ 1660 | ≥ 1650 | ≥ 1680 | ≥ 1670 | |

Permanent Linear Change, % | 1500º CX4h, ± 0.2 | 1450º CX2h, ± 0.5 | ||||||

- Q: The specific content is what gb/t2608-2012 brick

- Quality assessment procedures, packaging, marking, transport, storage, and quality certificates. Suitable for siliceous refractory bricks.

- Q: How much is the highest melting point of silicon?

- . True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. The total volume of heating to 1450 DEG about 1.5~2.2% expansion, the residual expansion will make cutting seam sealing, ensure masonry tightness and good structure strength, so that the brick load softening temperature will reach 1750 degrees Celsius above 1620 degrees in the case of the highest melting point.

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- The share of A12O3 and SiO2 is different

- Q: The brick is mainly used in the place?

- Open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts.

- Q: Can iron oxide be used as refractory material?

- Iron oxide can not be used as refractory material, but it can be used as refractory additive. Iron oxide can be used as pigment

- Q: Why is the three oxidation of two silicon is very harmful impurities in silica brick

- Can generate the material needs is the best way to see the impurity problem!! the first consideration is whether can get the material impurities with what method choice after the time! Miscellaneous reactions cannot have new impurity formation! Selected cannot and need material reaction reagent!

- Q: Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q: Common bond brick?

- Lime should contain a lot of active CaO, I decompose CaCO3 and MgCO3 not more than 5%, Al2O3+Fe2O3+SiO2 no more than 5%. When the content of large particles, burned Ca-CO3 and over burned lime, the product produced caves, affecting the quality of products.

- Q: Brick

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature.

- Q: Why in the production of the brick to detect the volume density

- Density is the property of material, different density of materials, density of the same kind of material is not up to standard, affecting performance.

Send your message to us

Silica Brick for Glass Furnace G-97A

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords