Aluminum Foil Facing Shielding Copper Polyester Foil for Aluminum Foil Shielding

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Mylar foil Shielding Foil for Coaxial Cable communication cable

1.Structure of Aluminum Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Aluminum Mylar foil Shielding Foil:

Aluminum Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

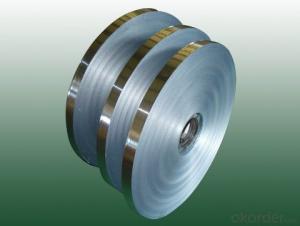

3. Aluminum Mylar foil Shielding Foil Images

4. Aluminum Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

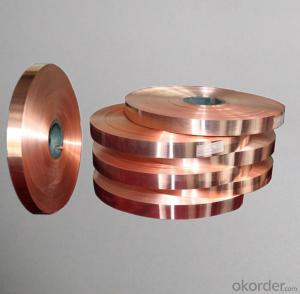

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: This question asks for instructions on how to use aluminum foil as a wrapping material for food.

- <p>To use aluminum foil facing to wrap food, first ensure the foil is clean and free of tears. Cut a piece of foil large enough to fully cover the food item. Place the food in the center of the foil. Bring up the sides of the foil and fold them over the food, sealing the edges tightly to prevent air and moisture from entering. For more secure wrapping, double fold the edges or use a crimping technique. For items like fish or meat, you can also create a sealed pouch by folding the foil over the food, then folding the edges inward and crimping to close. Always handle food with clean hands or utensils to maintain hygiene.</p>

- Q: This question asks for methods to prevent aluminum from aluminum foil leaching into food.

- <p>To avoid aluminum from aluminum foil leaching into your food, use the foil sparingly and avoid wrapping food directly in it. Opt for heavy-duty aluminum foil, which is less likely to tear and expose food to aluminum. When cooking acidic or salty foods, consider using parchment paper or silicone baking mats as alternatives. Additionally, avoid using aluminum foil at high temperatures, as this can increase the risk of aluminum transfer. Finally, store food in glass or stainless steel containers instead of aluminum foil to minimize exposure.</p>

- Q: Describe the process of aluminum foil facing in a few sentences.

- <p>Aluminum foil facing is a process used to laminate aluminum foil to a substrate, typically for decorative or functional purposes. The process begins with the preparation of the substrate, ensuring it is clean and free of contaminants. Then, a layer of adhesive is applied to the substrate. The aluminum foil is then placed onto the adhesive-covered substrate and pressure is applied to ensure proper adhesion. The laminated product is then cured, which can involve heat or UV light to set the adhesive. Finally, the product is trimmed and inspected for quality before being packaged and shipped. This process is used in various industries, including construction, automotive, and consumer goods.</p>

- Q: What are the eco-friendly options available to replace plastic containers?

- <p>Yes, there are several alternatives to plastic containers that are more environmentally friendly. Glass containers are a popular choice due to their durability and ability to be reused multiple times. Stainless steel containers are also a great option as they are long-lasting and do not leach chemicals. Biodegradable materials like bamboo, silicone, and certain types of plant-based plastics are other alternatives. Additionally, using cloth bags or reusable food wraps can help reduce the need for single-use plastic containers.</p>

- Q: What are some methods to avoid aluminum foil sticking to food while cooking or baking?

- <p>Yes, there are several ways to prevent aluminum foil from sticking to food. You can lightly grease the foil with cooking spray or oil before placing the food on it. Alternatively, you can use parchment paper or a silicone baking mat between the food and the foil. Another method is to dampen the foil slightly with water, which can create a barrier. Using a non-stick aluminum foil designed for cooking can also be effective. Remember to handle the foil carefully to avoid tearing, especially when greasing or dampening it.</p>

- Q: This question asks for a comparison between aluminum foil facing and other types of metal foils, highlighting their differences.

- <p>Aluminum foil facing is distinct from other metal foils due to its specific properties. It is lightweight, highly reflective, and offers excellent heat conductivity, making it ideal for insulation and cooking applications. Unlike other metal foils, aluminum foil is non-toxic and can be safely used in food packaging and preparation. It is also corrosion-resistant and has a lower melting point compared to metals like steel or copper, which affects its usability in various industries. Additionally, aluminum foil is more affordable and widely available than some other metal foils, contributing to its popularity in everyday use.</p>

- Q: The user is asking if it's possible to use aluminum foil facing, which is a type of reflective material, for making desserts.

- <p>Yes, you can use aluminum foil facing in the process of making certain desserts, particularly for baking. It can help reflect heat in the oven, ensuring even cooking and browning. For example, when making meringues or pavlovas, aluminum foil can be used to catch any drips from the oven. However, it's not typically used as an ingredient in the dessert itself. Always ensure that the foil is food-safe and follows any specific recipe guidelines regarding its use.</p>

- Q: Is it safe to use aluminum foil with a shiny side to wrap food for grilling?

- <p>Yes, you can use aluminum foil facing to wrap food for grilling. The shiny side of aluminum foil is non-stick and is safe for use with food. It helps prevent food from sticking to the foil and allows for even cooking. However, ensure that the foil does not come into direct contact with the heat source as it may cause the foil to tear or burn, potentially releasing aluminum particles into the food. Always follow grilling guidelines and safety precautions to avoid any risks.</p>

- Q: This question asks about the various types of aluminum foil facing that can be found in the market.

- <p>Aluminum foil facing is commonly used in construction for insulation and moisture protection. The different types available on the market include: 1) Plain Foil Facing, which is a simple, smooth aluminum surface; 2) Embossed Foil Facing, featuring a textured pattern for added strength; 3) Reinforced Foil Facing, which incorporates additional materials for enhanced durability; 4) Coated Foil Facing, where the aluminum is coated with other substances to improve performance; and 5) Laminated Foil Facing, which combines aluminum with other materials for specific applications. Each type serves different purposes and has unique properties that cater to various construction and industrial needs.</p>

- Q: Explain the distinction between aluminum foil insulation with and without a vapor barrier.

- <p>Aluminum foil insulation with a vapor barrier is designed to prevent moisture from passing through, which is crucial in humid environments to prevent condensation and mold growth. The vapor barrier is a layer that acts as a moisture control, enhancing the insulation's effectiveness. On the other hand, aluminum foil without a vapor barrier does not have this moisture-resistant layer, making it less effective in controlling moisture and potentially leading to condensation issues. The presence of a vapor barrier can also impact the thermal performance and energy efficiency of the insulation.</p>

Send your message to us

Aluminum Foil Facing Shielding Copper Polyester Foil for Aluminum Foil Shielding

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords