Shell NO.6 Pump Accessories in investment casting

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Made of 304 stainless steel products, mainly used in the impeller of the pump equipment. Products for OEM type, requires customers to drawings or samples for mold making, casting, machining and other processes.

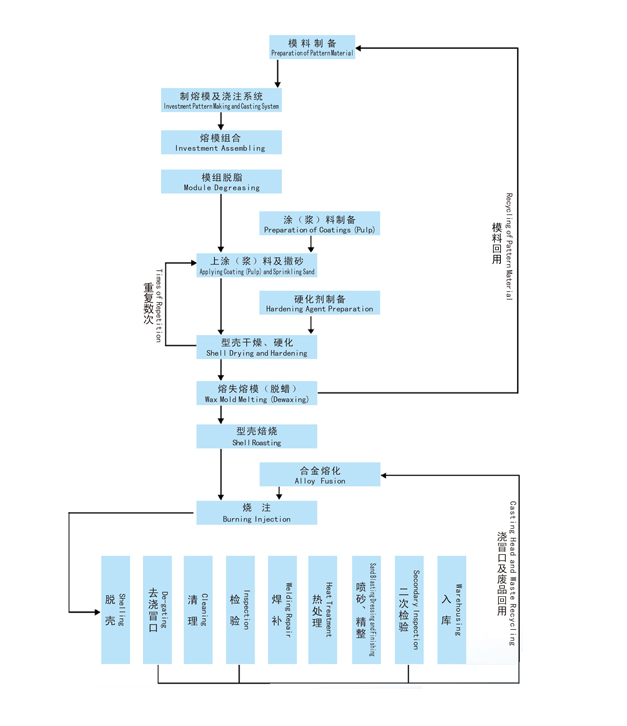

Process flow diagram:

Factory photos:

Taigang Investment Casting Co.,Ltd. (hereinafter referred to as Taigang) affiliated with Shandong Taishan Iron and Steel Group Co., Ltd., founded in 2000, covers an area of 10000 m2,has skilled workers and qualified engineers.Taigang is a member of China Foundry Association, had passed the ISO 14001:2004 EMS and ISO 9001:2008 QMS. With independent import and export right, Taigang sales products to South Korea, USA, Italy, Turkey, Spain, Japan and other countries.

Taigang is mainly engaged in the development and manufacture of precision castings, focuses on the research of water pump spare parts, Min impeller passage width is up to 4 mm.Taigang has an advanced precision casting production lines (silica sol lost wax process), an alloy casting lines (lost foam process), a CNC machining workshop (with output value of RMB 1.5 million yuan per month), aheat treatment workshop and many advanced test equipments,such as spectrometer, three-dimensional coordinate detector etc ,so as to have the ability to manufacture qualified castings. Now Taigang has the capacity of 1000 tons for precision castings per year, 1500 tons for heat resistant steel products per year, annual sales income adds up to 100 million yuan.

With the help of high quality and good reputation,Taigang wins high praise not only from the domestic clients,but also from abroad.Taigang is willing to cooperate with the vast number of foreign clients hand in hand and to achieve a win-win goal.

- Q: The casting defects of pores, trachoma how to repair?

- Airhole above 2mm recommended LT101 casting defect repair agent. If repair quality requirements, high availability LT111 iron repair agent, LT112 steel repair agent, LT113 aluminum repair agent, LT114 copper repair agent.

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- The three methods of metal processing have one thing in common. They are hot working, which are different in temperature and range of processing. Ductile cast iron is widely used because of its brittleness and poor impact. Heat treatment of cast iron usually adopts the annealing process, reduce the casting effect: 1 because of the internal stress caused by the thermal expansion and contraction, reduce the deformation after machining, decrease surface hardness, improve machining conditions;

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- The types and uses of foundry sand according to the mineral composition of different silica sand and non siliceous sand is divided into two categories. The main mineral composition of silica SiO2.: natural silica sand used for non-ferrous metal casting, cast iron and steel castings in small sand and core sand. The selection of natural silica sand: used in organic matter as the binder of various sand and core sand. The artificial sand for sand and core sand castings. Non siliceous sand and non siliceous sand have many kinds and different uses. Limestone sand: crushed by limestone, the main mineral composition is CaCO3, used for casting sand and core sand. Zirconium sand: the main mineral composition is ZrO2 SiO2, used for large steel castings and alloy steel pieces of core sand or sand surface sand, or powder used as coating. Magnesia: the main mineral composition is MGO, used for high manganese steel casting surface sand, core sand, and its powder can be used as coating. Chromite ore: the main mineral composition is chromite FeO. Cr2O3, used for large or special casting steel surface sand, core sand, its powder can be used as coating.

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- Mainly because of the cooling shrinkage caused by internal stress caused. There is the change of temperature distribution in materials element imbalance, is typical of surface and internal, thin wall and thick wall, bottom and top.

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- The finish of reaming depends on the material and the sharpness of the reamer, as well as the speed and speed of the top and bottom. Marine machine tool

- Q: How can the casting be quenched and tempered?

- Return, general castings (especially steel castings) commonly used heat treatment process is normalized and tempered. Of course there are completely by annealing or remove stress annealing...

- Q: Can the casting part be phosphating with the phosphating solution of the pickling board?

- Phosphating. But it's not necessary. Because casting parts have strong corrosion resistance.

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- Processing stainless steel materials, you can use YG class tools, such as YG8, YG8N. The tool geometric parameters g0=15 degrees to 18 degrees, a0=6 degrees to 8 degrees, kr=75 degrees, ls=-5 degrees to -8 degrees; cutting amount is Vc=43 m/min, ap=0.3 to 0.5 mm, f=0.16mm/r.

- Q: Shandong foundry, casting small pieces of precision casting

- Dongying Huayang precision casting factory, the smallest to do 2G pieces.

Send your message to us

Shell NO.6 Pump Accessories in investment casting

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches