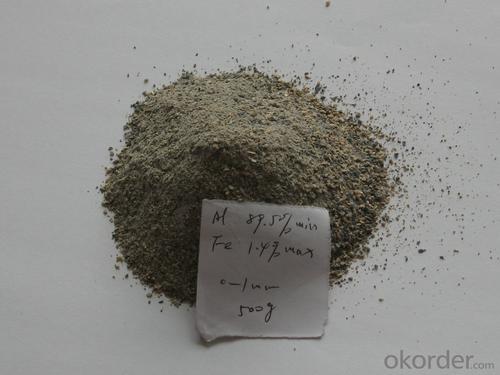

Raw Materials for Refractory:Shaft Kiln Bauxite Al2O3 75-95%

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Hebei, China (Mainland) | Shape: | Powder, powder | Material: | bauxite |

| SiO2 Content (%): | 7-14% | Al2O3 Content (%): | 80-87% | MgO Content (%): | 0.3% |

| CaO Content (%): | 0.3% | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 3% |

| SiC Content (%): | 2.4% | Model Number: | CNBM | Brand Name: | Banyue |

| color: | white,khaki | Dimensions: | 120mesh,200mesh,325mesh | Application: | refractory product |

| Chemical Composition: | Al2O3, CaO, Fe2O3 |

Packaging & Delivery

| Packaging Details: | 50kg/bag, or according to customer requirements customized. |

| Delivery Detail: | 10 days |

Product Description

Content | 1 | 2 | 3 | 4 |

Al2O3 | 80%min | 85%min | 86%min | 87%min |

SiO2 | 14%max

| 9%max

| 8.5%max

| 7%max

|

Fe2O3 | 2.5%max | 2.0%max | 2.0%max | 2.0%max |

TiO2 | 4.0%max | 4.0%max | 4.0%max | 4.0%max |

CaO+MgO | 0.6%max

| 0.6%max

| 0.6%max

| |

K2O+Na2O | 0.3%max

| 0.3%max

| 0.4%max

| 0.6%max

|

B. D. | 2.6g/ccm min. | 3.10g/ccm min. | 3.10g/ccm min. | 3.0-3.10g/ccm |

H2O | 0.5%max | |||

Refractoriness | 1770° < Refractoriness< 2000° | |||

NO. | Size | Size Distribution | ||

1 | 0-1mm | 0-0.5mm 60%max | ||

2 | 1-3mm | 90% min | ||

3 | 3-5mm | 90% min | ||

- Q: What is the importance of silicon powder in refractory processing?

- it can certainly improve the fire resistance

- Q: How long is the fire resistance time of the AAAfire resistance rolling shutter door?

- How long is the fire resistance time of the AAA fire resistance rolling shutter door?

- Q: What's the heat conductivity coefficient of fire-resistant material?

- 5~5 (Unit: W·m-1·K-1). The symbols are λ or K. Thermal conductivity and material properties Thermal insulation material generally is 0, and is related to organizational structure and working temperature. Thermal conductivity of the material refers to the heat transferred from from one plane to another plane in 1 seconds. Generally the thermal conductivity of fire-resistant material is 1. The larger the value is, the stronger the thermal conduction performance is. If the temperature of two planses differes for 1K, then the thermal conductivity is 03~1. The plane cover 1square meter.

- Q: Refractory factory grinding brick dust harmful to the body?

- The effect is very large and belongs to lung disease.

- Q: What things and cement mixed can act as refractory?

- This has a lot. I suggest you can check monolithic refractories.

- Q: How should refractory cement be used?

- Types of refractory mortar Refractory mortar can be divided into the following types: casting of fire mortar: also known air setting fire mortar. It is used as a protective refractory layer in the kiln head burner, as a refractory material in some parts of preheater, and it is generally constructed by grouting. b: Insulation fire mortar: It is used to repair the deformed plane of the kiln shell, or for thermal insulation of the roof in the cooler. Refractory mortar: It is also known as thermosetting fire mortar, mainly used in brick masonary. When using, we must add the glassy water to stir. (silicic acid sodium, water, NaSiO3, H2O). General DiDOTECT 135 (having a heat resistance of above 1350 degrees Celsius) SK34 is used in the kiln tail. DiDOTECT 150 (having a heat resistance of above 1500 degrees Celsius). SK35 Couprit 160H is used under high temperature, and it is mainly used in the kiln head coal injection nozzle.

- Q: How should fireproof building materials be ranked?

- According to our national standard GB8624-97, the combustion performance of building materials are divided into the following levels: A class: Incombustible building materials: the material is almost incombustible. B1 class: Flame-retardant building materials: they are better in fire retardation. It is non-combustible when meeting open fire in the air or under high temperature, and it is difficult for the fire to spread quickly. Besides, when the fire source is removed, combustion stops immediately. B2 class: Combustible building material: It has certain fire retardation. In case of open fire in the air or at high temperature, it will immediately burst into flames, and easily lead to the spread of fire, such as the spread to wooden pillars, timber roof truss, timber beams, wood stairs, etc. B3 class: Flammable building material: It has no fire retardant effect at all, but is highly flammable with high fire risk. Hope my answer can be accepted.

- Q: What kind of refractory bricks material is best?

- 1, high alumina brick: The content of Al2O3 is more than 75. The refractoriness is higher than the clay brick. It has good resistance to acid, alkali and erosion and is suitable for cement kiln calcining zone and other places. It has long operation life, but the price is high. 2. dolomite?brick: Formation of coating has good performance, good corrosion resistance, but f-CaO is contained in bricks. It is hydratable and difficult to transport and keep, so it is less used in the production. 3. magnesia-chrome bricks: It has good formation of coating and is used for burning zone. The disadvantage is poor thermal shock resistant performance. Besides, positive Hexavalent Cr is highly toxic. Countries that produce and use magnesia-chrome bricks gradually decrease on the international. Now production units using this brick should find alternatives as soon as possible. 4. spinel brick: It is often used in transitional zone and has good seismic performance, good reduction resistance, but refractoriness is a little bit poor. 5. anti-stripping brick: This brick contains a small amount of ZrO. Martensite phase transformation happens to form thin crack during temperature-rise period. It has strong alkali?resistance, anti-stripping performance and good slag resistance. 6. phosphate brick: It has low refractoriness, but it has strong strength and good shock resistance. It is often used in grate?cooler, hot kiln hood, etc. 7. carborundum brick: It has high temperature resistance(1800 degree, softening temperature under a fixed load is 1620-1640), small coefficient of thermal expansion, high cold-resistance heat-resistance, abrasion resistance. It is suitable for cooling zone and kilneye. 8. silmo brick: It has good thermal shock resistance, high strength, good abrasion resistance, and is suitable for transitional belt.

- Q: What does refractory mean?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q: What level is the rock wool board fireproofing material ?

- The most important feature of the rock wool board is fireproofing, which is a non-combustible material and absolute A-level! It has the specialized external wall rock wool board, which can be found online.

Send your message to us

Raw Materials for Refractory:Shaft Kiln Bauxite Al2O3 75-95%

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords