SH15-M Amorphous Alloy Oil-immersed Transformer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

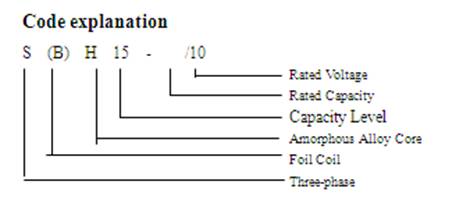

SH15-M Series

Amorphous Alloy Oil-immersed Transformer

Introduction of Products

Amorphous alloy isderived from iron, boron and other elements which rapid cooling down to mouldin order to arrange its atoms disordered. Compared with silicon sheets, the permeabilityof amorphous alloy is high, the no-load losses and current is lower, and moreoperation charges can be saved. Meanwhile, its heat is low,and it has good stability to make its working lifelonger.

Performance Characteristics

1. Saving power: The no-load losses reduce byabout 80% than that of S9 series.

2. Reliable: The capability of anti-shortcircuit is strong.

3. Protecting environment: Its noise is lowand it can decrease the discharging quantity of carbon.

Structure Characteristics

1. The core adopts three-phase five-limb and HV winding adopts D connection,which eliminates the three fluxes and three-harmonic electric potential anddecrease eddy current loss and temperature caused by leakage. Meanwhile, the steepnessof impulse voltage is reduced.

2. The coil takesthe shape of rectangular, and use conductor tensioning device to wind. Itadopts shaping, press mounting and other technique measures to make the outsidedimension of coil come to design requirement. And that HV coils wind outside LVcoils improve the strength of coil and the capability of anti-short circuit.

3. There is no oilstorage tank and moisture absorber on the oil tank. The transformer oil doesn’tcontact with the air and the expansion of oil depends on the elasticity of corrugatedplates to compensate. This can eliminate maintenance and improve working life.

Normal Using Condition

1. The altitude is not more than 1000m.

2. Environment temperature

Highest temperature: +40℃

Hottest monthly average temperature: +30℃

Highest yearly average temperature: +20℃

Lowest temperature: -40℃

3. Using outdoors( or indoors)

4. The wave shape of supply voltage is approximateto sine wave.

5. The supply voltage of three phases isgenerally symmetric.

If thetransformers need to be used at abnormal condition, the details should beoffered when the users order.

Main Specification and Technology Parameter

1. Range of rated capacity: 50~2500kVA

2. Rated voltage: not more than 10kv

3. Rated frequency: 50Hz

4. Insulating level

Voltage Grade (kv) | The highest voltage effective value of equipment(kv) | Rated short-time applied withstand voltage(kV/min) | Rated lightning impact withstand voltage(peak)(kv) |

≤1 | 1.1 | 3 | -- |

6 | 7.2 | 20 | 60 |

10 | 12 | 35 | 75 |

5. The insulating classof transformer is A, coil temperature rise is not more than 65K, and thetemperature rise of top oil is not more than 60K.

6. Thetransformers correspond with the following standards:

a. GB1094.1~2, GB1094.3, GB1094.5 Power transformer

b. JB/T 10318 Technology parameter and request of oil-immersedamorphous alloy core distribution transformer

c. Standard of InternationalElectro-technical Commission: IEC60076, Power transformer

d. Q/SIHG1 SH15-M Technology parameter andrequest of three-phase oil-immersed distribution transformer of amorphous alloycore sealed type

7. TechnologyParameter of SH15-M Series

Rated capacity (kVA) | Voltage and tapping range | Symbol of connecting group | No-load losses (W) | Load losses (W) | No-load current (%) | Impedance of short circuit (%) | ||

HV(KV) | Tapping range (%) | LV(kV) | ||||||

30 |

6 6.3 10 10.5 11 |

±5 ±2x2.5 |

0.4 |

Dyn11 | 33 | 630 | 1.7 |

4 |

50 | 43 | 910 | 1.3 | |||||

63 | 50 | 1090 | 1.2 | |||||

80 | 60 | 1310 | 1.1 | |||||

100 | 75 | 1580 | 1 | |||||

125 | 85 | 1890 | 0.9 | |||||

160 | 100 | 2310 | 0.7 | |||||

200 | 120 | 2730 | 0.7 | |||||

250 | 140 | 3200 | 0.7 | |||||

315 | 170 | 3830 | 0.5 | |||||

400 | 200 | 4520 | 0.5 | |||||

500 | 240 | 5410 | 0.5 | |||||

630 | 320 | 6200 | 0.3 |

4.5 | ||||

800 | 380 | 7500 | 0.3 | |||||

1000 | 450 | 10300 | 0.3 | |||||

1250 | 530 | 12000 | 0.2 | |||||

1600 | 630 | 14500 | 0.2 | |||||

2000 | 750 | 17400 | 0.2 |

5 | ||||

2500 | 900 | 20200 | 0.2 | |||||

Outline Dimension

Type | Outside dimension (mm) | Weight (kg) | |||

Length | Width | Height | Oil weight | Total weight | |

SH15-30 | 1100 | 690 | 1090 | 130 | 630 |

SH15-50 | 1190 | 750 | 1140 | 160 | 710 |

SH15-63 | 1250 | 750 | 1160 | 160 | 750 |

SH15-80 | 1290 | 750 | 1200 | 170 | 810 |

SH15-100 | 1260 | 800 | 1190 | 180 | 870 |

SH15-125 | 1320 | 810 | 1220 | 190 | 940 |

SH15-160 | 1370 | 810 | 1220 | 210 | 1050 |

SH15-200 | 1410 | 800 | 1320 | 230 | 1140 |

SH15-250 | 1490 | 810 | 1360 | 260 | 1290 |

S(B)H15-315 | 1520 | 790 | 1430 | 280 | 1500 |

S(B)H15-400 | 1670 | 820 | 1510 | 330 | 1710 |

S(B)H15-500 | 1650 | 910 | 1450 | 370 | 1960 |

SBH15-630 | 1830 | 920 | 1440 | 430 | 2250 |

SBH15-800 | 1910 | 950 | 1500 | 480 | 2730 |

SBH15-1000 | 2000 | 1100 | 1490 | 620 | 3330 |

SBH15-1250 | 2100 | 1100 | 1580 | 730 | 3560 |

S(B)H15-1600 | 2120 | 1240 | 1560 | 860 | 3830 |

A comparison about no-load losses of amorphous alloyand silicon sheet

Capacity (KVA) | No-load losses (w) | |

S9 type (silicon sheet) | SHI5 type (amorphous alloy) | |

100 | 290 | 75 |

315 | 670 | 170 |

500 | 960 | 240 |

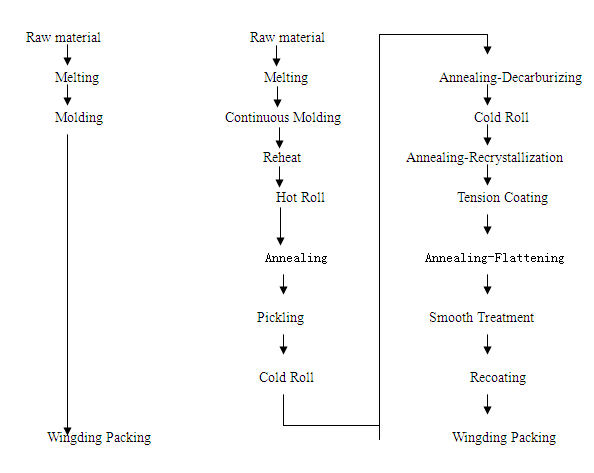

The Manufacturing Process of Amorphous Alloy Materials

a. The raw materials melt in the induction furnace.

b. The melted materials are transferred to feedingpart.

c. Control of casting head

d. After melting to be thin, it is sprayed to coolingwheel.

e. The sprayed materials cool down at the speed of 106℃ per second to form amorphous alloybelt.

f. Measure the width and thickness of alloy belt andfeedback to control system.

g. It is led to pull through unit.

h. Material receiving

A comparison to manufacturingprocess of amorphous alloy and silicon sheet

Amorphous alloy material Orientation silicon sheet

Social and Economic Effects

The manufacturingprocess of core materials of amorphous alloy core transformers is simple, andthe energy source losses are little, so the carbon discharge can be reduced.

No load losses are low, and the increased investment cost of transformers can be taken back within5 years.

Low operation temperature, small insulation deterioration, long working life.

The ordering basic data

1、Rated capacitance;

2、Rated voltage;

3、Rated frequency;

4、Tapping range;

5、Impedance voltage;

6、Using condition;

7、Other performance data should be indicated inthe contract.

- Q: best movie i everr seen, bein a transformers fan as a kid, this a whole nother level god damnn

- Well, you can call me nuts! It was so goood, I watched it FOUR times. Was worth it. To me, Transformers just broke the barrier when it comes to making robots that interact well with humans. The awesomely human-like behaviour of the Autobots, the cool action scenes, fast but cool transformations and the god-like Optimus Prime took my breathe away! Absolutely the best movie this year. No one could ask for a better live adaptation of a cartoon, especially one that we used to love

- Q: I am using an audio transformer in a schematic, but I don't understand why. Can someone explain how a 1000 ohm to 8 ohm audio transformer works? (Radio Shack #273-1380)

- I guess you know that if you use a transformer with two separate windings, they are electrically isolated. The audio transformer is used to match a 4 ohms load such as a speaker, to an amplifier which does well with say, a 100 ohms load. In that case, you use a step down transformer with ratio N 5. Note that N^2 is 25 and 100 ohms divided by 4 ohm is 25. The voltage is brought down by a factor of 5 while the current the transformer can deliver increases to five times that the amplifier can deliver. So it is used as an impedance matching device. Just as a 23VA transformer operate at 230V takes 100mA and delivers about 1 amp at 23V if it is a step down transformer of 10:1. the secondary voltage is 23V.

- Q: How many transformers games are for the xbox360 and what ones are based on the old tv show? And what ones are based on the movies? Please give complete names and in order! Thank you (:

- Hmm 'Play O' took my answer :(

- Q: I just finish watching Transformers Revenge of the Fallen for the third time. IT was awesome I 'm getting it on DVD and hoping for it to come out as another transformers.

- Paramount and DreamWorks took the unusual step today of announcing a release date for a movie that had yet to be greenlit. The studios claimed July 1, 2011 as the release date for Transformers 3. Paramount insiders told Variety that they wanted to lock down the July 4th weekend for a third film before another studio claimed the date. But, it's not an official announcement that Transformers 3 is a go. A writer for the third film has not been hired, and it's unknown whether director Michael Bay or stars Shia LaBeouf and Megan Fox would return for the third installment. Transformers 3 might also face a bit of difficulty lining up financing. Paramount managed to shoehorn Transformers 2 into its already completed Melrose II slate deal, but the studio currently has no follow-up long-term co-financing deal that they could use to help cover the costs of a third film. And since General Motors, which has been involved with Transformers and its sequel, might back out of marketing Transformers 2, we doubt they'll be onboard for a third film unless the company's financial condition improves dramatically. Paramount also moved up the release date of Marvel's Thor from June 16, 2011 to May 20, 2011. Considering that Marvel just announced Thor's release date last week and scooped Sony by announcing a release date for Spider-Man 4 at the same time, Paramount's move raises the question: Who sets the release dates for these Marvel productions: Marvel or the distributor?

- Q: If you have two 12 volt transformers and if we connect their hot wires together does the voltage become 24 or 12 volts? Please help, thanks so much!lt;3

- If you connect them in series, you will get 24 volts. It's not a real good idea to connect them in parallel.

- Q: I know there has been plenty of Transformers anime over the years, but is there any Transformers manga?

- Have you tried googling it? Good luck! I remember seeing Transformers in JPN since I was little I think they've been around since the 80s. At least I've seen the toys in JPN since then.

- Q: How many different types of transformers are there if anyone can remember from the cartoons?

- There's quite a lot

- Q: A 1:150 transformer has a primary voltage of 4500 V. (a) What is the voltage in the secondary coil? (b) If the transformer consumes 45 W, what are the currents in the primary and secondary coils?

- Secondary voltage is 4500*150 If transformer losses are neglected, and a load is assumed in secondary, the load resistance is E^2/P (4500*150)^2/45. Current in secondary 45/(4500*150). Pri current is 150 times current in secondary.

- Q: I can't remember the funny scenes from any the Transformers movies, especially 1 and 2.It's driving me nuts.I saw the third one just last week so I remember a couple of funny scenes, but other than that, no luck.If you can, could you please include a link to a video clip of the scene?Thanks so much! (:

- When the car turns into bumblebee and the guy says to the girl its probably japanese

- Q: What are the transformer capacity?

- Transformer capacity: 15,30 50 63 80 100 125 160 200 250 315 500 630 A high - speed range of 12500 .. The The The The (Unit: KVA) Small is less than 1600KVA Medium 1600--6300KVA Large 8000 - 63000KVA Extra large is greater than 63000KVA

Send your message to us

SH15-M Amorphous Alloy Oil-immersed Transformer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords