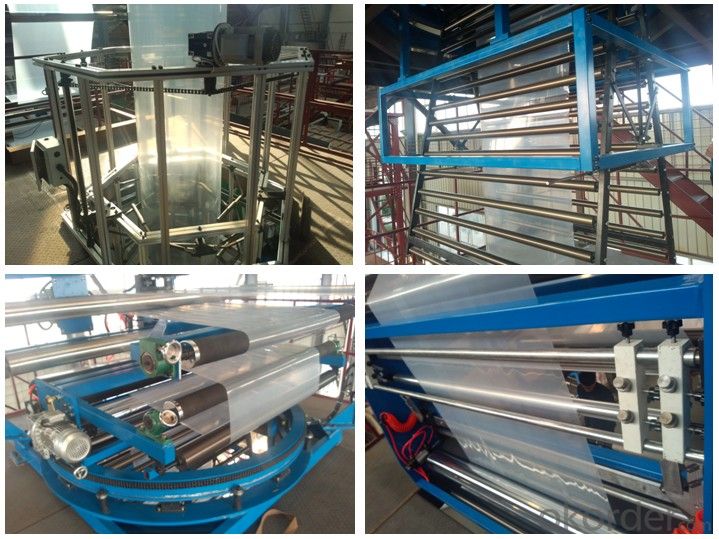

Seven layer Film Blowing Machine for Food Package

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1, Main Technical Parameters

1.1 Product Specification: Width 1400mm Thickness 0.025~0.120mm

1.2 Suitable Materials: LDPE, LLDPE, mPE, EVA or mixed materials.

1.3 Product Quality: Film thickness and limit deviation: 0.025~0.060mm≤±8%

0.061~0.120mm≤±7%

1.4 Total Installed Power: About 170KW

1.5 Maximum Output: About 170Kg/h

1.6 Dimensions: (L×W×H): 9.75×6.6×9.0m

1.7 Total Weight: About 18tons

1.1 Product Specification: Width 1400mm Thickness 0.025~0.120mm

1.2 Suitable Materials: LDPE, LLDPE, mPE, EVA or mixed materials.

1.3 Product Quality: Film thickness and limit deviation: 0.025~0.060mm≤±8%

0.061~0.120mm≤±7%

1.4 Total Installed Power: About 170KW

1.5 Maximum Output: About 170Kg/h

1.6 Dimensions: (L×W×H): 9.75×6.6×9.0m

1.7 Total Weight: About 18tons

2, Configuration

2.1 Extrusion system (Extruder)

Equipped with 5sets of SJ55x32 and 2set of SJ65x32 single screw extruder which have

advantages of good production efficiency, low energy

consumption and good plasticization.

2.2 Die head system

Die head is introduced the advanced German technology, through CAD optimal design,

processed with German TC2.8K four-axis simultaneous machining center. The die will have

features of high precision, good brightness without deformation.

2.3 IBC system

IBC (ultrasonic closed-loop servo-control) system is consists of gas exchange device,

internal cooling air ring, in/out air blower, signal detection and control circuits, etc. The

system can rapidly cooling the bubble, exhaust inner heat, water molecules and emissions

of bubble, supply new cooling air, cool the inner temperature of the bubble, increase the

production output and improve the mechanical properties of films.

2.4 Traction system

Horizontal ±360°reciprocating rotary can guarantee the linear velocity of film product

always stay consistent. The driving mechanism, haul off device and V-shaped plate hauls

the bubble for 360°uniform rotary at the speed of 0.1-0.3r/min to make the film deviation

which caused by die head, air ring and tower frame being 100% randomly distributed, thus,

to guarantee the whole quality of formed film product.

2.5 Automatic winding system

With the features of advanced technology, safe operation, easy maintenance, the winding

system can automatically change, cut and unload the rolls, which highly reduces the labor

costs and enhances the effectiveness.

2.6 Computer control system

Control method: Mitsubishi PLC control technology

2.6.1 One set of main control cabinet, adopts one set of three-in-one cabinet. (AC

contactor, low voltage fault positioner from Schneider, SSR from Taiwan Yangming)

2.6.2 Display part: adopts 10.4" touch screen for the operation (traction, winding, metering,

IBC, synchronous tension, cooling control of inlet/outlet blower).

2.6.3 Yaskawa frequency inverter for extruder motors, and domestic frequency inverters for

the rest.

- Q: What is the working vacuum in the oil filter?

- The existing vacuum oil filter machine technical indicators only vacuum oil filter and coalescence vacuum oil filter two, so to answer this question, you need to understand the principle of vacuum oil filter, vacuum oil filter machine work, need to vacuum oil filter in the outside atmospheric pressure and oil filter in the vacuum pump under the action of the suction filter, large particle impurities are removed by the oil heater into the precision filter, filter the impurity particles fine before entering the water filter, separated out from the oil droplet, the precipitation in the water reservoir. The oil solution for removing impurities and large water drops enters a three-dimensional vacuum flash tower for further treatment of micro water.

- Q: I change the oil machine! I recently changed my false engine oil! It ran 2000 kilometers! Can you change the oil filter instead of the engine oil?

- No way! It's best to change it! The residual oil in the oil filter will react with the new engine oil!

- Q: What parameters should be provided for purchasing turbine oil filters?

- A lot of oil filter of inferior machine companies to deceive the user know the truth that the oil filter filter frame function filter can filter water, water; second, when the specific choice of the model, to clear the outlet pipe diameter, so the oil pipelines do not match, the other day, demanding too much less oil, is still not online centralized filtering stop filtering, will determine the size of the flow. The reason to mention the size of the flow, because the flow of oil filters higher prices, buy small and not enough, suitable for the best, buy high, expensive

- Q: Peanut oil centrifugal filter and vacuum oil filter which is good?

- To make the machine longer to use, you need a clean oil system that will minimize the loss of lubricating oil and maintain a high degree of cleanliness, so that your maintenance costs can be reduced. Now you will have the best oil purification system in the world: that is a true centrifugal purifier.

- Q: What are the main use of oil filters?

- Gas stations, oil producing enterprises, etc., as long as the used oil can be used

- Q: Classification of oil filters According to the principle of the oil filter

- Viscosity of oilHigh viscosity oil can not pass through fine screen, so it is necessary to reduce the accuracy. Because: (1) filter often plug, need frequent cleaning, or even replace the filter.(2) the increase of the axial pressure, the oil can quickly pass filter, but tend to crush the filter.(3) adding preheated fuel tank to increase temperature and reduce viscosity.Generally speaking, the filtration precision of the fine filtration stage is chosen as:(1) insulating oil, choose 1~5 mu m.(2) lube oil and turbine oil under 46, select 10~20 mu m.(3) internal combustion engine oil and gear oil are chosen 20~50 mu m.

- Q: Difference between low speed and high speed of centrifugal oil filter

- Then, the centrifugal oil filter can control the size of centrifugal force indirectly through the rotation frequency of the centrifuge, so as to realize different filtering effects. At high speed, the centrifugal force is great

- Q: Why is there a load switch, no oil filter?

- It is connected to the transformer, and has been working online, as to some of the switches

- Q: Who knows what the vibration of the oil filter is?

- Generally, the vibration of oil filters is very harmful: vibration, noise, accelerated wear of bearings, shortening of mechanical life, and serious damage accidents.There may be four reasons:1, the anchor screws loose. Solution: just tighten it2, the uneven thickness of sludge. Solution: clean the residue

- Q: Pressure filter and vacuum oil filter how to choose, prompt only know productivity Q

- There are numerous particles of hundreds of microns to zero microns in oil, and industrial filters can not eliminate particles contaminated below 10 m, and precise filtration can only be filtered to 5 m. Analysis of the content of contaminated particles in oil, the smaller the particle content, and if more than 1 mu of M pollution particles were set to 100%, then the content of pollution particles above 10 mu m is only 10%. That is to say, in general, the filter based oil purifier can only filter less than 10% of the contaminated particles, and our company's electrostatic oil purifier can effectively remove 0.1 M of contaminated particles.

Send your message to us

Seven layer Film Blowing Machine for Food Package

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches