Self-Climbing Concrete Placing Boom HG32A-3R

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

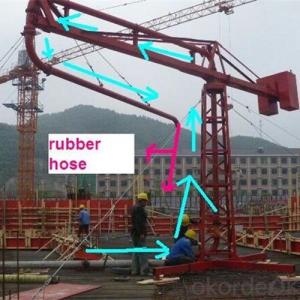

The placing boom has a Z and R-shaped booms assembly with three or four foldable sections, which can swing through 360 degrees while luffing, folding/unfolding, thus allowing it to place concrete to form walls, pipes, columns, piles and other vertical structures without confined placement areas.

The boom assembly’s luffing; folding/unfolding and swinging are carried out hydraulically with buttons. The hydraulic and electrical system feature overload protectors, flow controls, alarms, phase sequence protectors and so on, which ensures the placing boom to have reliable performance, easy and smooth operation, and high safety.

Scope of Application of the Equipment

The HG32A concrete placing boom is a concrete placer for combined use with a concrete pump in concrete placement operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This equipment can only be used in concrete construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The equipment is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Product Advantages:

OKorder's Concrete placing boom Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (20-40 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Product Specifications:

Dimensions and masses of the complete machine and its major components

Model | HG32A | |

Delivery pipe dimension (outside diameter×thickness) JJ83(mm×mm) | Φ133×4.5 | |

Delivery hose dimension (inside diameter×length) (″×mm) | 5″×3000 | |

Radius of placing boom(m) | 31.7 | |

Stationary height(to the join between the end of the boom and Swivel table (m) | 22.6 | |

Three hydraulic foldable arms | 1st section | 14.5m |

2nd section | 9.2m | |

3rd section | 8.0m | |

Boom articulation | 1st section | 0°~86° |

2nd section | 0°~180° | |

3rd section | 0°~180° | |

Slewing range(°) | 360 | |

Power of motor(kW) | 15 | |

Pressure of hydraulic system (MPa) | 28 | |

Type of hydraulic oil | ESSO NUTO H46/H32 | |

climbing | working pressure (MPa) | 25 |

climbing speed (m/min) | 0.56 | |

Mode of operation | cable remote control radio remote control | |

power | 380V/50Hz | |

wind speed | Placing concrete | ≤13.8m/s |

Climbing | ≤7.9m/s | |

working temperature | -20~48℃ | |

FAQ:

Q1: How to control the Placing Boom?

A1: The control system has two control modes for the user's selection: wireless remote control, and panel control.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Placing Boom according to customers request?

A4: Yes, we can produce Concrete Placing Boom according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Images:

- Q: What are the specifications of concrete spreader?

- The frame is arranged on the rotary supporting seat, the rotary support can be rotated 360 degrees, the first two girder from the upper pipe support to securely and support cloth rod pipeline transportation, the rear counterweight to achieve balance

- Q: How to install and use the distributor?

- Install the fuse according to the electricity consumption. No steel, aluminum or zinc wire shall be used instead of the fuse.

- Q: What are the acceptance items of concrete spreader?

- The installation site should be carried out in advance according to the requirements of construction site should be collected, must be stable and firm installation, foot pad.

- Q: What is a fixed concrete distributor?

- Internal climbing concrete distributing machine is a kind of distributing equipment for high-rise building concrete construction. The ship borne concrete distributor is a special ship loading equipment for construction and design of harbors and docks

- Q: What do concrete pumps and fabrics mean?

- People need to arrange for pouring concrete tubing, split pipe, guard, pump handle up too much trouble

- Q: what's the difference between the fabric pump and boom pump?

- The inner climbing type distributor is not limited by height

- Q: What are the weekly inspection items for concrete spreader?

- Check connection bolts, shaft end plate, pin shaft, lock nut is loose

- Q: How to maintain the concrete spreader?

- Cloth machine material, Doumen hoist hydraulic with accumulator, can quickly open and close, accurate cloth, prevent residual material fall, pneumatic closed lax

- Q: How to distinguish tower type distributor and general distributor?

- Avoid large arm distortion caused by huge pressure and vibration of concrete pump during construction

- Q: What is the concrete distributor?

- According to the pouring concrete construction environment different and individual requirements, has designed a climbing and walking type, ship type, manual type and other models for the user, the formation of HG series concrete mixer is currently the world's most complete specifications

Send your message to us

Self-Climbing Concrete Placing Boom HG32A-3R

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords