Self-Climbing Concrete Placing Boom HGB33

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

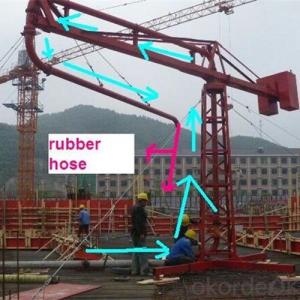

The placing boom has a Z-shaped boom assembly with three foldable sections, which can swing through 360 degrees while luffing, folding/unfolding, thus allowing it to place concrete to form walls, pipes, columns, piles and other vertical structures without confined placement areas.

The boom assembly’s luffing; folding/unfolding and swinging are carried out hydraulically with buttons. The hydraulic and electrical system feature overload protectors, flow controls, alarms, phase sequence protectors and so on, which ensures the placing boom to have reliable performance, easy and smooth operation, and high safety.

Scope of Application of the Equipment

The HG33A concrete placing boom is a concrete placer for combined use with a concrete pump in concrete placement operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This equipment can only be used in concrete construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The equipment is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Transport

Because of the structure of this machine is huge, it needs pay special attention to give the arm adequate stability during the journey. The parts that over-long or over-width need disposal depend on national traffic law. The safety hook should be put up .The arm assembly must be supported by its forward end on a support trestle of adequate load-bearing capacity. In order to avoid oil pipe from extrusion, crosstie under the arms is needed.

In order to transporting conveniently, divide the machine into some big units.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Product Specifications:

Dimensions and masses of the complete machine and its major components

Technical Specifications of the concrete placing boom

Model | HG33A | ||

Delivery pipe dimension (outside diameter×thickness) JJ83(mm×mm) | Φ133×4.5 | ||

Delivery hose dimension (inside diameter×length) (″×mm) | 5″×3000 | ||

Radius of placing boom(m) | 32.44 | ||

Stationary height(to the join between the end of the boom and swivel table) (m) | 22.6 | ||

Four hydraulic foldable arms(m) | 1st section | 9.51 | |

2nd section | 7.56 | ||

3rd section | 7.65 | ||

4th section | 7.72 | ||

Boom articulation(°) | 1st section | 0°~86° | |

2nd section | 0°~180° | ||

3rd section | 0°~180° | ||

4th section | 0°~180° | ||

Slewing range(°) | 360 | ||

Power of motor(kW) | 22 | ||

Pressure of hydraulic system (MPa) | 28 | ||

Type of hydraulic oil | ESSO NUTO H46/H32 | ||

(m)Interval of climbing frame | Climbing | 3.0~4.2 | |

Placing concrete | 6.0~8.4 | ||

Resting | |||

Mode of operation | cable remote control | ||

radio remote control | |||

power | 380V/50Hz | ||

wind speed | Placing concrete | ≤13.8m/s | |

Climbing | ≤7.9m/s | ||

working temperature | -20~48℃ | ||

FAQ:

Q1: How to Erection and Dismantling Placing Boom?

A1: Have the concrete foundation on which the cruciform base is to be erected prepared in accordance with the requirements. Ensure the verticality of the centerline of the cruciform base and level surface less than 1/500. Prepare a private power supply box for concrete placing boom at the worksite. Connect the power supply box with transformer station of the worksite directly using cable.

Q2: what is a General requirement of erecting and dismantling?

A2: The workers who erect or dismantle the equipment must be skilled, familiar with the performance and features of the equipment, and have ability to deal with fault. During erecting or dismantling, all workmen must obey the director's command.

Work off the court neatly, and enclose it with flag-bar, forbid other people come in. Adopting valid precaution prevent workmen from being hurt by falling block. The workmen must wear safety helmet and safety shoes, tie safety belt according to the demand of working at high place. In big thunderstorm, heavy snow, thick fog and the wind speed over 7.9m/s (wind force up to 4) conditions, erecting and dismantling are forbidden.

Before working, check the equipment carefully to clear all the hidden trouble.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Placing Boom according to customers request?

A4: Yes, we can produce Concrete Placing Boom according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Images:

- Q: What are the specifications of concrete spreader?

- A counterweight box is arranged on the balance frame. It settled in the main beam rear connecting flange, screw firmly, to ensure the stability of the incident

- Q: What are the acceptance items of concrete spreader?

- The installation site should be carried out in advance according to the requirements of construction site should be collected, must be stable and firm installation, foot pad.

- Q: How to fit the cloth rod of the distributor?

- Check whether the bolts of the rod are fully tightened and whether the shaft is normal

- Q: What do concrete pumps and fabrics mean?

- Cloth machine, cloth form and automobile pump is similar, it is to use conveyor belt in the state without pressure to transport concrete, cloth machine is relatively heavy, slow walking, and the delivery of concrete material falls easily aggregate segregation

- Q: What are the weekly inspection items for concrete spreader?

- The conveying straight pipe and the 90 degree bent pipe on the rack shall be rotated 180 degrees after the completion of a certain amount of transportation so as to increase the service life.

- Q: What is the Hand operated concrete distributor?

- Concrete pump is a supporting equipment, and the concrete pump connected to expand the scope of concrete pumping

- Q: What are the monthly inspection items of the movable concrete spreader?

- Check the insulation resistance of the circuit of the motor, the grounding of the electrical equipment, metal case and metal structure

- Q: How to distinguish tower type distributor and general distributor?

- The steel spreader and the circular pipe distributing machine of the general distributing machine are all simple structures,

- Q: What is the structure of a concrete distributor?

- A composite movement consisting of two parts of a rotating frame covers all cloth radius points

- Q: What are the benefits of concrete handling machines?

- The concrete distributing machine saves the material and saves the tower crane

Send your message to us

Self-Climbing Concrete Placing Boom HGB33

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords