Seamless steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A106 GR.B Fluid Seamless steel pipe API5L X42 Seamless Pipe

API5L X52 Seamless Pipe Structure Seamless Steel Pipe

Product Descriptions

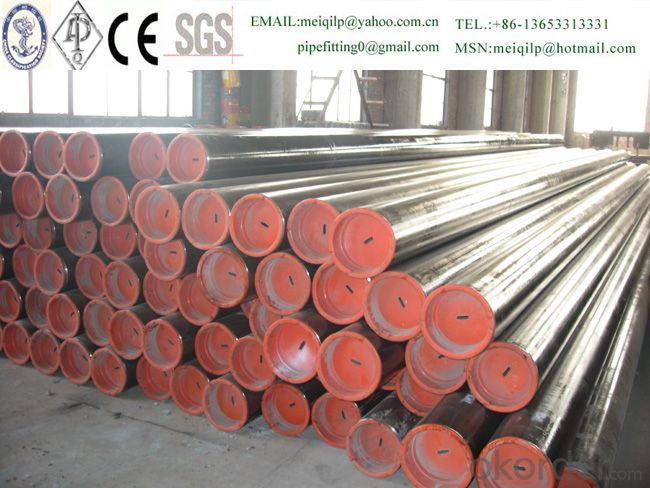

Product name: Seamless steel pipe

Outside Diameter : 1/2" -24"

Walk Thickness: 5-30mm(SCH 10---SCH XXS)

Length: 5.8m, 6m, 11.8m,12m or as customer's requirements

Standard: ASME , ANSI, DIN,GB8162/8163,GB 3087, JIS, API 5L ,EN10216

Material: ASTM A 179 ,A106Gr B/C,API5L Gr.B, X42,X46,X52,X56,X60,X70, API 5CT J55, K55 ,N80 , L80,P110,A335 P91,A335P92,

A335P11 , A335P22,A335P5,A335P9,A691Gr11,34Mn6, 20G,20#, 10#,

Process: Hot rolled and Cold drawn

Package:Painting ,Bevel End ,with plastic cap ,in bundles

Certification: ISO9001,ASME , API 5L, CE,CCS

Application : It is widely used in mechanical processing,Petroleum,chemical, transportation ,gas, water,shipbuilding and construction industry

Third Party Inspection:OMIC,SGS,BV ,TUV

Loading Port: Tianjin xingang /Shanghai/Qingdao

Payment Term: L/C,T/T

Minimum Order : 10 tons or negotiation

Supply Ability:20000 T/Month

- Q: Can steel pipes be used for oil and gas well production?

- Yes, steel pipes can be used for oil and gas well production. Steel pipes are commonly used in the oil and gas industry due to their high strength and durability, which allows them to withstand the harsh conditions of drilling and production processes. Additionally, steel pipes can efficiently transport oil and gas over long distances, making them a preferred choice in the industry.

- Q: How do you calculate the pipe friction loss for steel pipes?

- To calculate the pipe friction loss for steel pipes, you need to use the Darcy-Weisbach equation. This equation is commonly used in fluid dynamics to determine the pressure drop or friction loss due to the flow of fluid through a pipe. The equation is as follows: ΔP = (f * L * ρ * V²) / (2 * D) Where: ΔP = Pressure drop or friction loss f = Darcy friction factor L = Length of the pipe ρ = Density of the fluid V = Velocity of the fluid D = Diameter of the pipe The Darcy friction factor (f) is a dimensionless value that depends on the Reynolds number (Re) and the relative roughness (ε/D) of the pipe, where ε is the absolute roughness of the pipe. To determine the friction factor, you can use various correlations or Moody's diagram. Once you have the friction factor, you can plug in the values for length, density, velocity, and diameter into the equation to calculate the pressure drop or friction loss. It is important to note that the units of all the variables should be consistent (e.g., length in meters, density in kg/m³, velocity in m/s, diameter in meters) to obtain accurate results. By using this equation and obtaining the necessary parameters, you can calculate the pipe friction loss for steel pipes, which is crucial in designing and analyzing fluid flow systems.

- Q: Can steel pipes be used for both high-pressure and low-pressure systems?

- Yes, steel pipes can be used for both high-pressure and low-pressure systems. Steel pipes are known for their durability and strength, making them suitable for various applications, including both high and low-pressure systems. However, it's important to consider the specific requirements and regulations of the system to ensure the appropriate type and grade of steel pipe is selected for optimal performance and safety.

- Q: How are steel pipes used in the agriculture sector?

- Steel pipes are commonly used in the agriculture sector for various purposes such as irrigation systems, water transportation, and structural support for greenhouse structures. They are also used for the construction of livestock enclosures and handling equipment. Overall, steel pipes play a crucial role in ensuring efficient and reliable operations in the agriculture industry.

- Q: Are steel pipes suitable for use in hydropower plants?

- Yes, steel pipes are suitable for use in hydropower plants. Steel pipes offer several advantages such as high strength, durability, and corrosion resistance, making them ideal for transporting water or fluids in hydropower plants. Additionally, steel pipes can withstand high pressure and temperature conditions, ensuring smooth and efficient operation of the hydropower plant.

- Q: How do steel pipes compare to other pipe materials like PVC or copper?

- Steel pipes have several advantages over other pipe materials like PVC or copper. Firstly, steel pipes are incredibly durable and can withstand high levels of pressure and extreme temperatures, making them suitable for a wide range of applications. Secondly, steel pipes have excellent resistance to corrosion, which ensures their longevity and reduces the need for frequent maintenance or replacement. Additionally, steel pipes have a higher strength-to-weight ratio compared to PVC or copper, making them more robust and capable of handling heavy-duty tasks. However, steel pipes can be more expensive and require special equipment for installation. Overall, steel pipes are a reliable and versatile option that offers superior durability and performance compared to other pipe materials.

- Q: What is the role of steel pipes in the chemical manufacturing industry?

- Steel pipes play a crucial role in the chemical manufacturing industry as they are widely used for transporting various chemicals, gases, and liquids. These pipes are highly durable, resistant to corrosion, and can withstand high temperatures and pressures, making them ideal for handling hazardous substances. Additionally, steel pipes ensure the integrity and safety of the chemical manufacturing process by preventing leaks, contamination, and loss of product.

- Q: Seamless steel pipe and welded pipe what is the difference?

- Identification method: see the inside of the pipe, because the external, will deal with the welded pipe is inside a gap, you can see some, some, is not easy to see, you can slowly by hand touch, or see the specifications are relatively thin, welded pipe

- Q: What is the difference between hot-finished and cold-finished steel pipes?

- Distinguishing hot-finished and cold-finished steel pipes can be done by examining their manufacturing processes, which lead to different characteristics and applications. To create hot-finished steel pipes, a solid steel billet is heated to a high temperature and then pierced to form a hollow tube. This process, known as hot rolling, ensures that the steel is easily shaped and malleable. As a result, hot-finished steel pipes have rough surfaces and rounded edges. They are generally larger in diameter and have thicker walls. These pipes are commonly utilized in industries that demand high strength and pressure resistance, like the oil and gas sector, structural projects, and heavy machinery manufacturing. On the other hand, cold-finished steel pipes are produced using a process called cold drawing. This involves pulling the hot-finished steel pipe through a die at room temperature to reduce its diameter and achieve the desired shape. The cold drawing process yields a more precise and smoother finish for the steel pipes. Cold-finished steel pipes possess smoother surfaces and sharper edges compared to their hot-finished counterparts. They are typically smaller in diameter and have thinner walls. Cold-finished steel pipes are commonly applied in industries that require accurate dimensions, such as automotive part manufacturing, construction component fabrication, and machinery production. In conclusion, the primary disparity between hot-finished and cold-finished steel pipes stems from their manufacturing processes, resulting in variations in surface finish, dimensions, and applications. Hot-finished pipes are suitable for applications that demand high strength and pressure resistance, while cold-finished pipes are ideal for applications that require precise dimensions and smooth surfaces.

- Q: How are steel pipes used in HVAC systems?

- Steel pipes are commonly used in HVAC systems for various purposes. They are used for transporting fluids such as water, steam, and refrigerant throughout the system. These pipes are durable and resistant to high temperatures and pressures, making them suitable for the demanding conditions of HVAC applications. They are used for distributing and circulating the heated or cooled air, as well as for connecting different components of the system, including boilers, chillers, heat exchangers, and air handlers. Additionally, steel pipes are often used for ventilation and exhaust purposes in HVAC systems.

Send your message to us

Seamless steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords