Seamless Steel Pipe of 5 Inch API 5L GRAD B

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1、Structure of Seamless Steel Pipe of 5 Inch API 5L GRAD B Description:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of the Seamless Steel Pipe of 5 Inch API 5L GRAD B:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

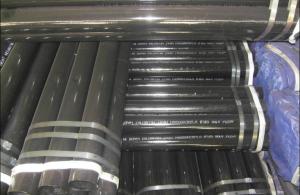

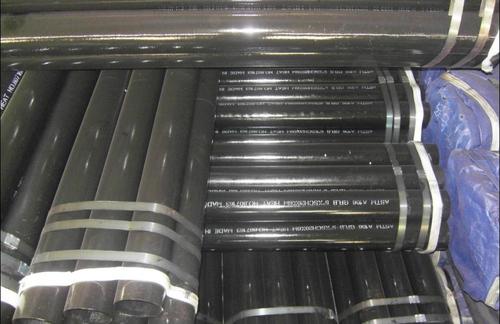

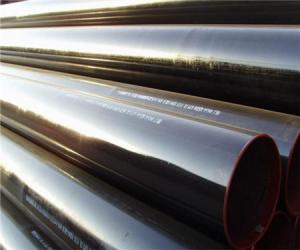

3、Seamless Steel Pipe of 5 Inch API 5L GRAD B Images:

4、Seamless Steel Pipe of 5 Inch API 5L GRAD B Specification:

1. Commodity Name: Seamless steel pipe

2. Standard: API,GB,ASTM,ASME,DIN

3. Quality grade: 10#, 20#, A106B, A53B, API 5L B, Q235, Q345, ST37-2, ST 45, ST52.etc.

4. Dimension:

OD: 1/2"-24"

WT: 2.5-80mm, SCH10~SCH40~XXL

length: 5.8m,6m,8m,9m,12m

5. Technique: Hot Rolled/Cold Rolled/ Cold Drawn

6. application

carbon seamless steel pipes are widely used in gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

7. Payment Terms: L/C D/A D/P T/T

8.packing and shipment

Packaged in bundles,as per customers' requirements, it can also bepackagesd as beveled ends, typed marking, black painting, plastic caps protection,woven bags packing

For 20" container the max length is 5.8m; For 40" container the max length is 12m. other options are available based on customer requests. Please discuss when placing orders.

5、FAQ of Seamless Steel Pipe of 5 Inch API 5L GRAD B:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: What are the different types of steel coatings used for pipes?

- There are several types of steel coatings used for pipes, including epoxy, polyethylene, polypropylene, and fusion bonded epoxy (FBE) coatings. Each of these coatings provides different levels of corrosion resistance and protection, making them suitable for various applications and environmental conditions.

- Q: Can steel pipes be used for cooling systems?

- Steel pipes are a viable option for cooling systems. They are frequently employed in different scenarios, such as cooling systems, because of their robustness, strength, and ability to withstand high temperatures and pressure. Industrial cooling systems, in particular, benefit from steel pipes due to the harsh environmental conditions and corrosive fluids they often encounter. Moreover, steel pipes possess outstanding heat conductivity, which facilitates efficient heat transfer, rendering them a dependable choice for cooling purposes. Furthermore, steel pipes can be easily tailored, joined, and adjusted to fulfill specific cooling system needs. Nevertheless, it is crucial to ensure that the steel pipes utilized are adequately coated or insulated to prevent corrosion and minimize heat dissipation.

- Q: How are steel pipes used in water transportation?

- Steel pipes are commonly used in water transportation systems as they are strong and durable, allowing for the safe and efficient delivery of water. These pipes are used to create networks that transport water from sources like reservoirs or treatment plants to homes, businesses, and other areas where water is needed. Steel pipes offer excellent corrosion resistance, ensuring the water remains clean and uncontaminated during transport. Additionally, their seamless construction minimizes leakage and ensures a consistent flow of water, making them an ideal choice for water transportation infrastructure.

- Q: What are the different methods of pipe coating for steel pipes?

- Steel pipes can be coated using various methods, each with its own benefits and uses. One widely used technique is fusion bonded epoxy (FBE) coating. This involves heating the steel pipe and applying a thermosetting powder that melts and sticks to the surface, resulting in a robust and long-lasting coating. FBE coating is excellent for preventing corrosion and is commonly employed in the oil and gas industry. Another method is liquid epoxy coating, where a liquid epoxy resin is applied to the steel pipe's surface. Once it cures, it forms a protective barrier. Liquid epoxy coating is suitable for smaller pipes and provides good resistance to chemicals. Polyethylene (PE) coating is a popular option, especially for pipes that will be buried underground. It involves wrapping the steel pipe with a layer of polyethylene, which offers exceptional resistance against water, chemicals, and abrasion. Polyurethane (PU) coating is another choice, known for its high chemical resistance and flexibility. It is often used in offshore applications and extreme temperature environments. Other pipe coating methods include coal tar enamel (CTE) coating, which provides excellent water and chemical resistance, and concrete weight coating, which adds weight to the pipe for stability in underwater or subsea applications. To summarize, the available methods for coating steel pipes include fusion bonded epoxy (FBE), liquid epoxy, polyethylene (PE), polyurethane (PU), coal tar enamel (CTE), and concrete weight coating. The selection of a coating method depends on specific requirements, such as corrosion protection, chemical resistance, or stability.

- Q: How are steel pipes used in the aerospace industry?

- The aerospace industry extensively utilizes steel pipes for various purposes. Aircraft frames heavily rely on steel pipes as they offer the necessary strength and structural integrity. Steel pipes find applications in the fuselage, wings, and landing gear of airplanes, as well as in rocket launch vehicles and space shuttles. The aerospace industry favors steel pipes due to their exceptional strength-to-weight ratio. They possess lightweight properties while maintaining immense strength, enabling the construction of robust and dependable aerospace structures. This aspect proves crucial in the industry as weight reduction significantly improves fuel efficiency and overall performance. Steel pipes also serve the purpose of transporting fluids and gases within aircraft systems. They commonly operate in the hydraulic and fuel systems, facilitating the flow of vital fluids like hydraulic fluid, fuel, and coolant. By ensuring the safe and efficient movement of these fluids throughout the aircraft, steel pipes contribute to its proper functioning and performance. Furthermore, steel pipes find utility in the aerospace industry for heat transfer applications. They form an integral part of the aircraft's cooling systems, aiding in the dissipation of heat generated by engines, electrical components, and other systems. With their exceptional thermal conductivity, steel pipes effectively transfer heat away from critical areas, preventing overheating. In conclusion, steel pipes possess a crucial role in the aerospace industry. They contribute to aircraft construction by providing strength and structural integrity, as well as facilitating fluid and gas transportation and heat transfer. The utilization of steel pipes in the aerospace industry ensures the safety, efficiency, and reliability of aerospace structures and systems.

- Q: What are the different methods of pipe insulation for steel pipes?

- There are several methods of pipe insulation for steel pipes, including foam insulation, fiberglass insulation, mineral wool insulation, and reflective insulation. Foam insulation is a popular choice as it provides excellent thermal insulation and is easy to install. Fiberglass insulation is another common option that offers good thermal and acoustic insulation properties. Mineral wool insulation is known for its fire resistance and is often used in high-temperature applications. Reflective insulation, on the other hand, utilizes a reflective surface to reduce heat transfer and is commonly used in hot climates.

- Q: What is a valve and how is it used in steel pipes?

- A valve is a device used to control the flow of fluid or gas in a pipe system. In the context of steel pipes, valves are typically installed at specific points along the pipeline to regulate the flow, stop or start the flow, and control the pressure of the fluid or gas. These valves can be manually operated or automated, allowing for efficient control and maintenance of the steel pipe system.

- Q: What is the process of coating steel pipes?

- The process of coating steel pipes involves applying a protective layer on the surface of the pipe to prevent corrosion and increase its durability. This typically includes cleaning the pipe to remove any contaminants, followed by applying a primer to improve adhesion. The pipe is then coated with a layer of paint or a specialized coating material using a variety of techniques such as spraying, dipping, or electrostatic application. The coated pipe is then cured or dried to ensure the coating adheres properly. This process helps to ensure the longevity and performance of steel pipes in various applications.

- Q: What are the typical lengths of steel pipes?

- The typical lengths of steel pipes vary depending on the industry and application. However, common lengths for steel pipes range from 18 to 40 feet.

- Q: What is the difference between seamless and welded steel pipes?

- The main difference between seamless and welded steel pipes lies in their manufacturing process. Seamless steel pipes are made by piercing a solid billet to form a hollow tube, while welded steel pipes are formed by rolling a flat sheet of steel into a tube and then welding the seam. This difference in manufacturing leads to varying characteristics such as strength, appearance, and cost. Seamless pipes are generally considered to have higher strength and are more aesthetically pleasing, but they are also more expensive to produce. Welded pipes, on the other hand, are more cost-effective and suitable for less demanding applications.

Send your message to us

Seamless Steel Pipe of 5 Inch API 5L GRAD B

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords