Seamless Steel Pipe China ASTM A106/A53/API5L Gr.B Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

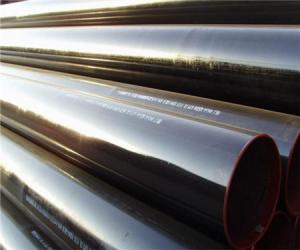

1、CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B description:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell.

As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable.

Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B Features :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Standard :ASTM A106, ASTM A53, ISO3183-2-1996

● Application: To be used for conveyance of petroleum, gas and conveyance of other fluid.

Standard: GB3087: Seamless Steel Tubes for Low and Medium Pressure Boiler

● Application: For manufacturing heating-pipelines, containers, steaming pipelines of low or medium pressure

boilers (p≤450℃, work pressure ≤5.88 Mpa)...

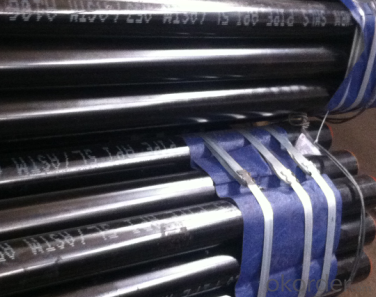

4、Packaging & Delivery of CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 30-45days after received 30%TT |

FAQ of Seamless Pipe ASTM A106/53:

①Quality

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②Price

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

Why us?

▲ CNBM is a state owned enterprise, which background ensures it of funds support and preferential policies

provide by ministry of commerce.

▲ CNBM enjoys a sound reputation both at home and aboard. The company stands a first-rate credit status

and has gained the access to preferential loans through a lot of international banking organizations.

▲ The company is renowned of it manufacturing capabilities and overall sourcing abilities. It has a long

track proven record of strategic cooperation with leading players in steel industry.

▲ Brand name “CMAX” commit to the best quality products and high cost effectiveness which ensures your

company a booming development & success.

Professional teams ensure a high efficiency of your purchase

▲ Professional sales team

▲ Professional engineering and technology team

▲ Professional exportation and contract processing/management team

▲ Professional cooperators and partners

Looking forward to doing the corporation with you

Any question, kindly feel free to contact us !

CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B Images:

- Q: What is the difference between steel pipes and copper-nickel pipes?

- Steel pipes and copper-nickel pipes differ in terms of their composition and properties. While steel pipes are primarily made of steel, copper-nickel pipes are composed of a mixture of copper and nickel. This difference in composition leads to variations in their strength, corrosion resistance, and thermal conductivity. Steel pipes are generally stronger and more durable, making them suitable for high-pressure and heavy-duty applications. On the other hand, copper-nickel pipes have excellent corrosion resistance, particularly in marine environments, and exhibit good thermal conductivity, making them ideal for heat transfer applications. Ultimately, the choice between steel pipes and copper-nickel pipes depends on the specific requirements and conditions of the intended use.

- Q: Can steel pipes be used for steam applications?

- Yes, steel pipes can be used for steam applications. Steel pipes have high strength and durability, making them suitable for carrying high-pressure steam. They can withstand the high temperatures and pressures associated with steam, making them a reliable choice for steam transportation in various industries.

- Q: What is the minimum wall thickness for steel pipes?

- The minimum wall thickness for steel pipes depends on several factors, including the intended use of the pipe and the specific industry standards and regulations. In general, the minimum wall thickness is determined by considering factors such as the pipe's diameter, the material strength, and the pressure or load it will be subjected to during operation. For example, in the oil and gas industry, the minimum wall thickness for steel pipes is usually specified by industry standards such as API 5L or ASME B31.3. These standards take into account factors such as the pipe's diameter, the material's yield strength, and the maximum pressure it will be exposed to. In other applications, such as structural or mechanical engineering, the minimum wall thickness for steel pipes is determined based on factors such as the pipe's intended load-bearing capacity, the desired safety factor, and any applicable building codes or regulations. It is important to consult the appropriate industry standards, codes, or regulations to determine the specific minimum wall thickness requirements for steel pipes in a given application.

- Q: What are the different methods of inspecting steel pipes?

- There are several methods of inspecting steel pipes, including visual inspection, ultrasonic testing, magnetic particle testing, dye penetrant testing, radiographic testing, and eddy current testing.

- Q: What is the difference between standard wall thickness and extra-strong wall thickness steel pipes?

- The main difference between standard wall thickness and extra-strong wall thickness steel pipes lies in their thickness and durability. Standard wall thickness pipes have thinner walls and are suitable for most general applications, while extra-strong wall thickness pipes have thicker walls and are designed for heavy-duty or high-pressure applications. These extra-strong pipes offer enhanced strength and resistance, making them more reliable and suitable for handling extreme conditions or demanding projects.

- Q: What is ND steel pipe?

- ND steel also has the ability to resist chloride ion corrosion. ND steel pipe, the main reference indicators (70 degrees Celsius, 50%H2SO4 solution immersion 24 hours), and carbon steel, Japan imported similar steel, stainless steel corrosion resistance compared to higher than these steel grades. Products by domestic refineries and manufacturing units after the use of widely acclaimed, and achieved good results.

- Q: What are the typical lengths of steel pipes?

- The typical lengths of steel pipes vary depending on their intended use and application. However, common lengths for steel pipes range from 18 to 24 feet (5.5 to 7.3 meters).

- Q: What are the different types of valves used with steel pipes?

- There are several types of valves used with steel pipes, including ball valves, gate valves, globe valves, check valves, and butterfly valves.

- Q: What are the different types of steel pipes available in the market?

- In the market, one can find a variety of steel pipes, each designed for specific purposes and applications. Some of the commonly used types are as follows: 1. Carbon Steel Pipes: These pipes are widely utilized due to their strength and durability. They are primarily employed in industries like oil and gas, construction, and plumbing for fluid and gas transportation. 2. Alloy Steel Pipes: By combining carbon steel with different metals like chromium, nickel, or molybdenum, alloy steel pipes offer enhanced strength, corrosion resistance, and heat resistance. They find applications in high-pressure environments such as power plants and chemical plants. 3. Stainless Steel Pipes: Highly resistant to corrosion and oxidation, stainless steel pipes are suitable for applications requiring hygiene and durability. Industries like food processing, pharmaceuticals, and water treatment commonly use them. 4. Galvanized Steel Pipes: These pipes are coated with a layer of zinc to protect against rust and corrosion. They are commonly found in plumbing systems and structures like fences and handrails. 5. Seamless Steel Pipes: These pipes are manufactured without any welding or joints, resulting in a smooth and continuous surface. They are known for their high strength and are often used in high-pressure applications. 6. Welded Steel Pipes: Made by rolling or bending a flat steel plate into a cylindrical shape and welding the edges together, welded pipes find common usage in construction, oil and gas, and automotive industries. 7. ERW (Electric Resistance Welded) Steel Pipes: ERW pipes are produced by passing a high-frequency electrical current through a steel strip, causing it to heat and form a weld. They are widely utilized in plumbing, water wells, and structural support. 8. LSAW (Longitudinal Submerged Arc Welded) Steel Pipes: LSAW pipes are created by bending and welding steel plates into a cylindrical shape. They are commonly employed for long-distance transportation of large volumes of oil, gas, or water. These examples represent only a fraction of the diverse range of steel pipes available in the market. The choice of the appropriate pipe type depends on factors such as the intended application, environmental conditions, and budget constraints. Consulting with experts or professionals is crucial in determining the most suitable steel pipe for a specific project or application.

- Q: How are steel pipes coated for underground applications?

- Steel pipes are typically coated for underground applications using a variety of methods, including but not limited to hot-dip galvanizing, epoxy coating, and polyethylene wrapping. These protective coatings help prevent corrosion, increase the lifespan of the pipes, and ensure their reliability in underground environments.

Send your message to us

Seamless Steel Pipe China ASTM A106/A53/API5L Gr.B Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords