Seamless Steel Line Pipe API 5L X42 supplier

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of API 5L X42 Steel Line Pipe:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of API 5L X42 Steel Line Pipe :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、API 5L X42 Steel Line Pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of API 5L X42 Steel Line Pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

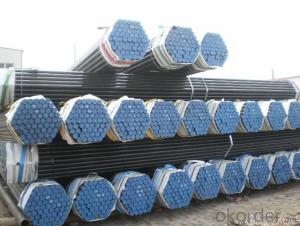

6、Seamless Pipe ASTM A106/53 Images:

- Q: What are the safety regulations for working with steel pipes?

- The safety regulations for working with steel pipes vary depending on the specific tasks involved, but some common regulations include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots, ensuring proper ventilation in enclosed spaces, following proper lifting techniques to prevent back injuries, implementing proper fall protection measures when working at heights, and using caution when handling tools and equipment to prevent accidents and injuries. It is important to consult the relevant guidelines and regulations specific to your jurisdiction and industry to ensure compliance and promote a safe working environment.

- Q: Are steel pipes fire-resistant?

- Indeed, steel pipes possess fire-resistant qualities. Being a non-combustible substance, steel does not ignite or aid in the propagation of flames. Steel pipes exhibit elevated melting points and can endure extreme temperatures, rendering them exceptionally fire-resistant. Consequently, they find widespread utilization in critical areas necessitating fire safety measures, including fire sprinkler systems, fire hydrant systems, and fire-resistant architectural frameworks. Moreover, the fire resistance capabilities of steel pipes are reinforced by their renowned robustness and resilience.

- Q: Can steel pipes be used for underground sewerage systems?

- Indeed, underground sewerage systems can make use of steel pipes. These pipes possess remarkable strength and durability, rendering them suitable for the transportation of sewage beneath the surface. Their resistance to corrosion is high, allowing them to withstand the pressure and weight of the soil above. Moreover, steel pipes boast an extended lifespan and exhibit resilience against environmental factors like moisture, chemicals, and temperature variations. Furthermore, the ease of welding steel pipes makes the process of installation and repairs more convenient. Nevertheless, it is crucial to ensure that these steel pipes are adequately coated or lined to prevent corrosion and comply with local regulations and standards pertaining to underground sewerage systems.

- Q: What are the advantages of using steel pipes in the manufacturing of storage tanks?

- There are several advantages of using steel pipes in the manufacturing of storage tanks. Firstly, steel pipes are highly durable and have a long lifespan, making them capable of withstanding high pressure and harsh environmental conditions. Secondly, steel pipes offer excellent resistance to corrosion, ensuring the integrity of the storage tank and preventing any leakage or contamination. Additionally, steel pipes are flexible and can be easily fabricated into various shapes and sizes, allowing for customization based on specific storage requirements. Lastly, steel pipes are cost-effective and readily available, making them a popular choice in the manufacturing industry.

- Q: How do you calculate the flow rate of water in steel pipes?

- To calculate the flow rate of water in steel pipes, you can use the equation Q = A × V, where Q represents the flow rate in cubic meters per second, A denotes the cross-sectional area of the pipe in square meters, and V represents the average velocity of the water in meters per second.

- Q: How are steel pipes used in the manufacturing of agricultural machinery?

- Steel pipes are commonly used in the manufacturing of agricultural machinery for various purposes such as structural support, fluid transportation, and protection. They are utilized to create the framework and chassis of the machinery, providing strength and durability. Steel pipes are also used to transport fluids such as fuel, water, and chemicals throughout the machinery. Additionally, steel pipes can be used to protect vulnerable components from external elements, ensuring the longevity and reliability of the agricultural machinery.

- Q: What is the maximum pressure that steel pipes can withstand?

- The maximum pressure that steel pipes can withstand depends on various factors such as the grade and thickness of the steel, the diameter and length of the pipe, and the specific application. However, steel pipes are known for their high strength and durability, allowing them to withstand significant pressures ranging from several hundred to several thousand pounds per square inch (psi).

- Q: What are the safety precautions for handling steel pipes?

- Some safety precautions for handling steel pipes include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots. It is also important to use proper lifting techniques to prevent strain or injury, as steel pipes can be heavy. Additionally, ensuring a clear and organized workspace, as well as securing the pipes properly during transportation, can help prevent accidents or damage.

- Q: Are steel pipes suitable for underground sewage systems?

- Yes, steel pipes are suitable for underground sewage systems. Steel pipes are known for their strength, durability, and resistance to corrosion, making them an ideal choice for underground installations. Steel pipes can withstand the pressure and weight of the soil above, ensuring the integrity of the sewage system. Additionally, steel pipes have a long lifespan and can withstand extreme temperatures and environmental conditions, making them a reliable choice for underground applications. However, it is important to note that proper coating and insulation should be applied to steel pipes to prevent corrosion and ensure longevity.

- Q: What are the different types of steel pipe supports for seismic applications?

- There are several types of steel pipe supports commonly used for seismic applications, including sway braces, rigid braces, snubbers, and restraints. Sway braces are designed to absorb lateral movement and provide flexibility during seismic events. Rigid braces, on the other hand, offer rigid support and resist movement. Snubbers are used to dampen pipe vibrations and prevent excessive movement. Restraints are used to anchor and limit the movement of the pipe during seismic activity.

Send your message to us

Seamless Steel Line Pipe API 5L X42 supplier

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords