Seamless Steel Pipe API 5L

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Seamless Steel Pipe API 5L

Product Descriptions : Carbon Seamless Steel Pipe

1.O.D:13.7mm~610mm

2.W.T:2.34mm~30mm

3.Length:5-12m

4.Certificate:API 5L,BV

WE SHALL DO OUR BEST TO OFFER YOU THE HIGH QUALITY PRDUCTS, THE MOST FAVOURABLE PRICE AND THE BEST SERVICE. LOOKING FORWARD TO YOUR INQUIRY.

| 1.COMMODITY NAME | Carbon Seamless Steel Pipe |

| 2.STANDARD | ASTM A106,ASTM A53,API 5L,ASTM A179 BS1387 GB/T8162-2008,GB/T8163-2008 A335 |

| 3.MATERIAL | API 5L X42,X52,X56,X60,X70 |

| 4.OUTER DIAMETER | 13.7-610MM |

| 5.WALL THICKNESS | 2.34-30MM |

| 6.LENGTH | 5.8-12M |

| 7.DELIVERY TIME | 20-30 DAYS AFTER SIGNING THE CONTRACT OR AS CUSTOMER' DEMAND |

| 8.BOTH OF ENDS | PLAIN ENDS OR BEVELED ENDS,PROTECTING CAPS |

| 9.PAKCING | IN BUNDLES TIED WITH STEEL STRIPS |

| 10.APPLICATION | A.CARRYING GAS,WATER OR OIL IN THE INDUSTRIES OF PETROLEUM AND NATURAL GAS B.FOR REFINERY,HEAT-EXCHANGING PIPE OR PIPELINE C.FOR HIGH-PRESSURE BOILER D.BUILDING-SHIP AND OVER-HEATE |

| 11.THE THIRD PARTY INSPECTION | SGS, BV OR AS CUSTOMER'S DEMAND |

| 12.PROCESS TECHLONOGY | COLD-DRAWN,HOT-EXPANDED,HOT-ROLLED |

| 13.CERTIFICATE | API 5L,API 5CT,ISO |

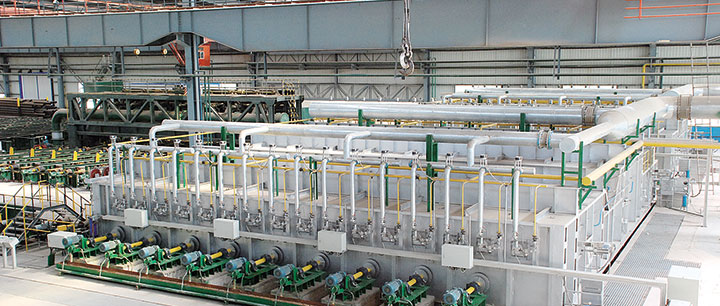

Dalipal Company is one of the most famous enterprises of china professionally producing pipeline and oil casing.We can supply API 5CT series of pipeline and oil casing with all kinds of specifications and materials.We have first-class production equipment and technology.

- Q: How are steel pipes inspected for compliance with industry standards?

- Steel pipes are inspected for compliance with industry standards through various methods, including visual examination, dimensional measurements, non-destructive testing, and mechanical testing. Trained inspectors carefully inspect the pipes to ensure they meet the required specifications, such as wall thickness, diameter, and surface quality. Non-destructive testing techniques like ultrasonic testing or magnetic particle inspection are used to detect any internal or surface defects. Mechanical tests, such as tensile or bend tests, are performed to evaluate the pipe's strength and ability to withstand pressure. These inspections help ensure that steel pipes meet the necessary industry standards and are fit for their intended use.

- Q: What are the properties of steel that make it suitable for pipe manufacturing?

- Due to its unique properties, steel is highly favored as a material for manufacturing pipes. The exceptional strength and durability of steel allow it to withstand high pressure and extreme temperatures, ensuring the safe transportation of fluids and gases over long distances without the risk of leakage or breakage. Another significant advantage of steel is its resistance to corrosion. Unlike other materials that can degrade when exposed to corrosive substances such as water, chemicals, and gases, steel remains highly resistant to corrosion. This quality makes steel pipes long-lasting and reliable. Furthermore, steel is a versatile material that allows for the production of pipes in various sizes and shapes. This flexibility enables customization to meet specific project requirements, making steel pipes suitable for a wide range of applications, including water supply, oil and gas transmission, sewage systems, and structural support. Moreover, steel possesses excellent thermal conductivity, which is crucial for applications involving the transportation of hot or cold fluids. Steel pipes efficiently transfer heat, ensuring minimal energy loss during the process. Additionally, steel is an environmentally friendly option for pipe manufacturing due to its recyclability. Steel pipes can be recycled and reused, reducing the demand for new raw materials and minimizing waste generation. In conclusion, the properties of strength, durability, corrosion resistance, versatility, thermal conductivity, and recyclability make steel the ideal choice for pipe manufacturing. These properties guarantee the reliability, efficiency, and longevity of steel pipes in various industries and applications.

- Q: How are steel pipes used in the construction of railways?

- Steel pipes are commonly used in the construction of railways for various purposes. They are primarily used in the fabrication of track structures, such as track supports, bridge components, and culverts. Steel pipes provide strength, durability, and resistance to external factors like corrosion and extreme weather conditions. They are also used for the transportation of fluids, such as water or fuel, within the railway infrastructure, ensuring efficient operation and maintenance of the system.

- Q: What is the difference between steel pipe and tubing?

- Steel pipe and tubing serve various purposes, but they possess distinct dissimilarities. The fundamental distinction between them stems from their shape and dimensions. Steel pipe, ordinarily circular in shape, features a hollow interior. It is manufactured in a range of sizes and thicknesses to accommodate diverse pressure and temperature prerequisites. Steel pipe frequently finds employment in construction, plumbing, and the oil and gas industries for the conveyance of fluids or gases. Conversely, steel tubing can adopt a variety of shapes, such as circular, square, and rectangular. Unlike steel pipe, tubing is typically evaluated by its outer diameter and wall thickness. Structural applications, such as building frames, automotive components, and machinery, often employ steel tubing. Another divergence between steel pipe and tubing lies in their manufacturing processes. Steel pipe is typically fashioned from solid steel billets, which are heated and stretched to produce a seamless or welded tube. On the other hand, tubing can be generated through diverse methods, including hot or cold rolling, welding, or extrusion. In terms of strength and durability, both steel pipe and tubing offer excellent qualities. Nevertheless, the particular requirements of the application will dictate which one is more suitable. Steel pipe is frequently selected for high-pressure or high-temperature applications, whereas steel tubing is favored for structural purposes or when a specific shape is necessary. In summary, the primary disparity between steel pipe and tubing resides in their shape, measurement techniques, and manufacturing procedures. While steel pipe possesses a round shape and is measured by its inner diameter, tubing can adopt various shapes and is usually measured by its outer diameter. Both steel pipe and tubing find extensive use in diverse industries, but the choice depends on the specific application and requirements.

- Q: How do you calculate the pipe pressure drop for steel pipes?

- To calculate the pressure drop in steel pipes, you can use the Darcy-Weisbach equation, which takes into account factors such as the pipe diameter, length, roughness, and the fluid flow rate. By plugging these variables into the equation, you can determine the pressure drop experienced by the fluid as it flows through the steel pipe.

- Q: How do you calculate the pipe pressure drop coefficient for steel pipes?

- To calculate the pipe pressure drop coefficient for steel pipes, you can use the Darcy-Weisbach equation. This equation relates the pressure drop in a pipe to various factors such as the flow rate, pipe diameter, pipe length, and the properties of the fluid being transported. The pressure drop coefficient, also known as the friction factor or the Darcy-Weisbach friction factor, is denoted by the symbol f. It is a dimensionless parameter that represents the resistance to flow in the pipe. The value of f depends on the flow regime, which can be laminar or turbulent. For laminar flow, which occurs at low flow rates or with viscous fluids, the pressure drop coefficient can be calculated using the Hagen-Poiseuille equation. This equation relates the pressure drop to the fluid viscosity, pipe length, pipe diameter, and flow rate. However, for turbulent flow, which occurs at higher flow rates, the calculation of the pressure drop coefficient is more complex. It depends on the roughness of the pipe wall, which affects the flow resistance. The roughness is typically quantified using the relative roughness, which is the ratio of the pipe wall roughness to the pipe diameter. To calculate the pressure drop coefficient for turbulent flow in steel pipes, you can use empirical correlations or Moody's diagram. Moody's diagram provides a graphical representation of the friction factor as a function of the Reynolds number and the relative roughness. The Reynolds number represents the flow regime and is calculated using the fluid properties, flow rate, and pipe dimensions. By finding the intersection of the Reynolds number and relative roughness on Moody's diagram, you can determine the corresponding pressure drop coefficient. It's important to note that the pressure drop coefficient for steel pipes may vary depending on the specific pipe dimensions, surface roughness, and fluid properties. Therefore, it is recommended to consult relevant standards or engineering references for accurate and up-to-date values of the pressure drop coefficient for steel pipes in your specific application.

- Q: Can steel pipes be used in high-pressure applications?

- Yes, steel pipes can be used in high-pressure applications. Steel pipes are known for their strength and durability, making them suitable for handling high pressures in various industries such as oil and gas, water distribution, and chemical processing.

- Q: What are the different types of steel pipe joints?

- There are several different types of steel pipe joints, including threaded, welded, flanged, grooved, and compression joints.

- Q: How are steel pipes used in agriculture?

- Various purposes in agriculture make steel pipes widely used, with one common application being irrigation systems. These pipes, known for their durability and ability to withstand water pressure, transport water from wells or reservoirs to different areas of farms, enabling efficient water distribution over long distances. Furthermore, steel pipes find utility in agricultural drainage systems. By removing excess water from fields, they prevent waterlogging and ensure proper drainage. Their resistance to corrosion is particularly significant in agricultural settings, where exposure to moisture and various chemicals is common. Moreover, steel pipes serve a vital purpose in the construction of greenhouse structures. They provide structural support for the greenhouse framework and facilitate the installation of irrigation systems and other equipment. The strength and sturdiness of steel pipes enable them to withstand harsh weather conditions, making them an ideal choice for greenhouse construction. Additionally, livestock farming benefits from the use of steel pipes. They are frequently employed in the creation of fences and enclosures for animals, providing a secure and long-lasting barrier. Steel pipes also play a crucial role in the construction of animal shelters and barns. To summarize, steel pipes play a crucial and versatile role in agriculture. They are integral components in irrigation systems, drainage systems, greenhouse construction, and livestock farming. Thanks to their durability, strength, and resistance to corrosion, steel pipes are an excellent choice for a wide range of agricultural applications.

- Q: Are steel pipes suitable for use in nuclear power plants?

- Yes, steel pipes are suitable for use in nuclear power plants. They are commonly used in various applications within the plants, including cooling systems, steam generation, and transporting fluids. Steel pipes offer excellent strength, durability, and resistance to high temperatures and pressures, making them ideal for handling the demanding conditions present in nuclear power plants. Additionally, steel pipes can be designed to meet the specific requirements of nuclear applications, ensuring their safety and reliability.

Send your message to us

Seamless Steel Pipe API 5L

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords