Seamless Carbon Steel Pipes With Reasonable Price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless Pipe ASTM A106/53:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of the Seamless Pipe ASTM A106/53:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

QUALITY ASSURANCE:

1) Strictly acc. ASTM,DIN,JIS,EN,GOST etc

2) Sample: We are accept your sample requirement

3) Test: Eddy current / hydrostatic/ Ultrasonic/ Intergranular Corrosion or according to customers' request

3) Certificate:API, CE ,ISO9001.2000.MTC etc

4) Inspection: BV,SGS,others is avaliable.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53:

①How is the quality of your products?

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

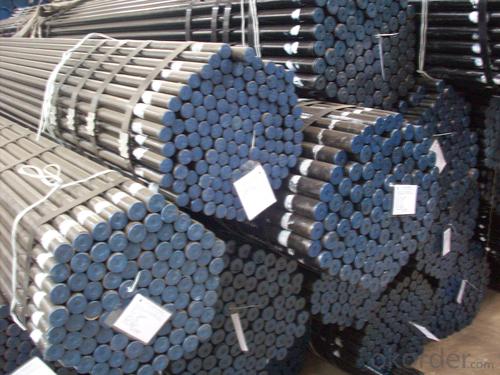

6、Seamless Pipe ASTM A106/53 Images:

- Q: What are the different types of steel coatings used for pipes?

- Some of the different types of steel coatings used for pipes include epoxy coatings, polyethylene coatings, fusion bonded epoxy (FBE) coatings, and zinc coatings.

- Q: Can steel pipes be used for underground irrigation systems?

- Certainly, underground irrigation systems can indeed utilize steel pipes. Steel pipes have gained popularity for irrigation systems owing to their exceptional durability, strength, and corrosion resistance. They have the capability to endure the immense pressure and stress associated with being buried underground, thus ensuring longevity without the need for frequent maintenance or replacement. Moreover, the smooth interior surface of steel pipes enables efficient water flow and minimizes the risk of clogging. Additionally, steel pipes are readily available in a variety of sizes and can be easily customized to meet specific requirements of irrigation systems. However, it is crucial to ensure that the steel pipes employed for underground irrigation systems are adequately coated or treated to prevent corrosion and extend their lifespan.

- Q: Can steel pipes be used for HVAC systems?

- Yes, steel pipes can be used for HVAC systems. Steel pipes are commonly used in HVAC systems for their durability, strength, and resistance to corrosion. They are suitable for transporting hot or cold air, water, or refrigerant throughout the system.

- Q: Can steel pipes be used in earthquake-prone areas?

- Indeed, in areas prone to earthquakes, steel pipes have the potential to be employed. Steel, as a durable and sturdy material, possesses the capacity to endure the forces generated during an earthquake. The malleability and pliability of steel facilitate the absorption and dissipation of seismic wave energy, thereby decreasing the likelihood of structural failure. Furthermore, the ability to weld steel pipes enables the construction of resilient and earthquake-resistant edifices. Nevertheless, it is crucial to adhere to appropriate engineering and construction practices to guarantee the proper installation and connection of steel pipes, thereby maximizing their capacity to withstand earthquakes. Additionally, it is imperative to consider local building codes and regulations to ensure compliance and safety in earthquake-prone regions.

- Q: How do steel pipes handle high-pressure applications?

- Steel pipes are able to handle high-pressure applications due to their inherent strength and durability. They have a high tensile strength and are resistant to deformation under extreme pressure. Additionally, the seamless construction of steel pipes ensures that there are no weak points or joints that can compromise their ability to handle high pressures.

- Q: What are the alternatives to steel pipes for various applications?

- There are several alternatives to steel pipes for various applications. Some common alternatives include pipes made from materials such as plastic (polyvinyl chloride or PVC), copper, cast iron, and ductile iron. Each alternative offers different benefits and drawbacks depending on the specific application, cost, durability, and environmental considerations.

- Q: What are the applications of steel pipes in the automotive industry?

- Steel pipes are commonly used in the automotive industry for various applications such as exhaust systems, fuel lines, and structural components. They offer excellent durability, corrosion resistance, and high tensile strength, making them ideal for carrying fluids and withstanding harsh environments. Additionally, steel pipes can be easily formed and welded, allowing for efficient manufacturing and assembly processes in the automotive sector.

- Q: How are steel pipes used in the construction of water supply systems?

- Steel pipes are commonly used in the construction of water supply systems due to their durability and strength. They are often used to transport water from the source to treatment plants, as well as for distribution to homes and businesses. Steel pipes are resistant to corrosion, which ensures the quality of the water and the longevity of the system. Additionally, their high pressure-bearing capacity makes them suitable for water supply networks that require efficient and reliable transportation of water.

- Q: What are the different types of steel pipe fittings for gas pipelines?

- There are several types of steel pipe fittings commonly used for gas pipelines, including elbows, tees, reducers, couplings, and flanges. These fittings are essential for connecting and directing the flow of gas within the pipeline system.

- Q: What are the safety precautions when working with steel pipes?

- When working with steel pipes, some important safety precautions to follow include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. Additionally, it is essential to ensure proper ventilation in the work area to prevent the accumulation of hazardous fumes or gases. Using the correct tools and equipment, such as pipe wrenches and clamps, and following proper lifting techniques are crucial to avoid strains or back injuries. Regular inspection and maintenance of the pipes and equipment are also necessary to prevent any potential accidents. Lastly, it is important to receive proper training and follow established safety procedures to minimize risks and promote a safe working environment.

Send your message to us

Seamless Carbon Steel Pipes With Reasonable Price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords