SCH40 ASTM A53 API 5L GR.B Carbon Seamless Steel Tubes STPG410 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Commodity Name: Carbon Seamless steel pipe

2. Standard: API,GB,ASTM,ASME,DIN

3. Quality grade: 10#, 20#, A106B, A53B, API 5L B, Q235, Q345, ST37-2, ST 45, ST52.etc.

4. Dimension:

OD: 1/2"-24"

WT: 2.5-80mm, SCH10~SCH40~XXL

Length: 5.8m,6m,8m,9m,12m

5. Technique: Hot Rolled/Cold Rolled/ Cold Drawn

6. Application:

Carbon seamless steel pipes are widely used in gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

7. Payment Terms: L/C D/A D/P T/T

8. Packing and shipment

Packaged in bundles,as per customers' requirements, it can also bepackagesd as beveled ends, typed marking, black painting, plastic caps protection,woven bags packing

For 20" container the max length is 5.8m; For 40" container the max length is 12m. other options are available based on customer requests. Please discuss when placing orders.

Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

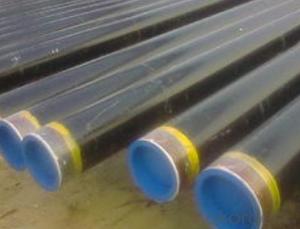

Seamless Steel Tubes Image

FAQ of Seamless Tube

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard. If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

We are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you have any question, pls feel free to contact us !

- Q: Can steel pipes be used in the oil and gas industry?

- Yes, steel pipes are commonly used in the oil and gas industry. Steel pipes are known for their strength, durability, and resistance to corrosion, making them suitable for transporting and storing various fluids and gases in the industry. These pipes can withstand high pressure and extreme temperatures, which are often encountered in oil and gas operations. Additionally, steel pipes can be easily welded together, allowing for efficient assembly and maintenance. Overall, steel pipes are a reliable and cost-effective choice for the oil and gas industry.

- Q: What are the factors that affect the pressure rating of steel pipes?

- The pressure rating of steel pipes can be influenced by various factors. These factors include the strength of the material used, the thickness of the pipe wall, the diameter of the pipe, the temperature at which it operates, its resistance to corrosion, compliance with manufacturing standards, and the impact of external loads. The strength of the steel plays a crucial role in determining the pressure rating. Steel with higher strength can handle higher pressure levels, while weaker grades may have lower ratings. Thicker walls provide more resistance against internal forces, allowing pipes to handle higher pressures. The diameter of the pipe also affects its pressure rating. Larger pipes generally have higher ratings due to their larger cross-sectional area. High temperatures can weaken steel, reducing its strength and pressure rating. Therefore, maximum operating temperature should be considered. Corrosion can weaken the pipe material over time, leading to a decrease in pressure rating. Factors such as fluid type, pH levels, and environmental conditions can impact corrosion resistance. Compliance with industry standards is crucial in determining pressure ratings. These standards ensure proper manufacturing techniques and materials are used. External loads such as soil settlement or traffic can affect pressure ratings. Proper design, installation, support, and protection are necessary to maintain the pressure rating. Considering all these factors and consulting industry guidelines is important for determining appropriate pressure ratings for steel pipes in different applications.

- Q: Can steel pipes be coated for aesthetic purposes?

- Yes, steel pipes can be coated for aesthetic purposes. Coating steel pipes not only adds a visually appealing finish but also provides protection against corrosion and other environmental factors. There are various coating options available for steel pipes, such as powder coating, epoxy coating, and vinyl coating, among others. These coatings can be applied in different colors and textures to enhance the appearance of the pipes and complement the surrounding environment. Whether in industrial settings, architectural projects, or decorative applications, coating steel pipes can transform them into visually appealing elements while maintaining their structural integrity.

- Q: What are the different types of coatings used for internal lining of steel pipes?

- There are several types of coatings commonly used for the internal lining of steel pipes, including epoxy coatings, polyurethane coatings, and cement mortar linings. These coatings are applied to protect the steel pipes from corrosion, improve the flow of fluids, and enhance the longevity and durability of the pipes.

- Q: Can steel pipes be used for underground drainage systems?

- Yes, steel pipes can be used for underground drainage systems.

- Q: What are the different standards for steel pipes?

- There are several different standards for steel pipes, including ASTM (American Society for Testing and Materials), API (American Petroleum Institute), and ASME (American Society of Mechanical Engineers). These standards specify the requirements for various aspects of steel pipes, such as their dimensions, chemical composition, mechanical properties, and testing procedures. These standards ensure that steel pipes meet the necessary quality and safety standards for their intended applications.

- Q: What kind of argon arc welding wire is used for 16Mn steel pipe?

- 16Mn steel weldability is very good, general use TIG with J50 welding wire, hand arc welding with J506, J507 and other welding rod

- Q: Can steel pipes be used for high-pressure applications?

- Yes, steel pipes can be used for high-pressure applications. Steel is known for its strength and resilience, making it a suitable material for handling high-pressure fluids or gases. Additionally, steel pipes can withstand extreme temperatures and are resistant to corrosion, further enhancing their suitability for high-pressure applications.

- Q: Is the steel frame on each floor supporting formwork (floor) called full scaffolding?

- The scaffold is also called full house scaffolding is a construction process for building a scaffold. Hall scaffolding relative to other scaffolding system density, that is, the house full of shelves. The full scaffolding is more secure than the rest of the scaffolding.

- Q: Can stainless steel pipes spray black paint?

- Can. The surface roughening with a thick gauze, do not use ordinary paint intensity difference. With resin paint, paint can be

Send your message to us

SCH40 ASTM A53 API 5L GR.B Carbon Seamless Steel Tubes STPG410 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords