SCD300 Single Cage/Twin Cage 3t Building Lift with Counter Weight

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Introduction :

Construction lifter is mainly used to transport people or goods to multistoried building.Buwidely applies to such contruction sites as industrial and civil architecture,bridge,underground,large chimney,and ship industry,etc.

Construction lifter has such advantages as steady property, safety, reliability, flexible carrying, and good adaptability, etc., improves working efficiency, and can reduce working intensity.

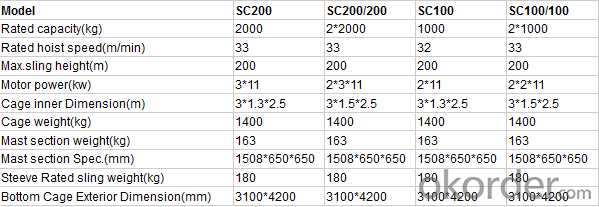

Parameter :

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

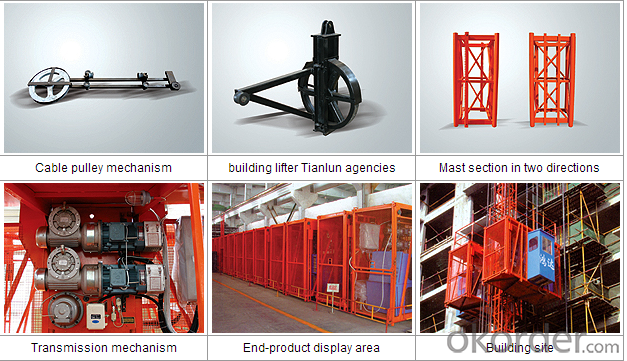

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

Brief Introduction about CNBM

1, CNBM is the biggest state-owned company which has had been awarded Qualified construction machinery manufactures and most of the big project are using our products.

2, CNBM possess key technical research department and could design & produce special machinery for international clients.

3, We have had passed ISO9001:2008,CE and etc.

4. The successful long-time construction machinery operation in the world testifies that the CMAX products’ performance is stable.

5. More than 10 overseas branch office provide immediate commercial convenience and after service.

6. We also has building hoist, suspended platform, formwork, etc. We also signed the strategic partnership with Tadano (China), XCMG, Zoomlion, Sany and other prestigious crane manufacturer, getting the competitive cost price from them, and using our overseas marketing channel to promote their brands. We can provider a series of equipment for your building company customer and supply a basket scheme for the final users.

7. We have built a cover 50,000 square meter logistic park in, Dubai UAE, will be a great guarantee of our business in middle east and nearby area.

- Q: What fundamental specifications or conditions must be met to operate a building hoist with a hydraulic pump?

- <p>To use a hydraulic pump to power a building hoist, several basic requirements must be met: a reliable power source, a suitable hydraulic pump with the correct pressure and flow rate, a robust and leak-free hydraulic system, safety mechanisms such as pressure relief valves and emergency stop features, proper installation and maintenance procedures, and adherence to safety standards and regulations. Additionally, the pump should be compatible with the hoist's design and capable of providing the necessary force and speed for lifting operations. Regular inspections and maintenance are crucial to ensure the hoist operates safely and efficiently.</p>

- Q: This question seeks to understand the benefits and drawbacks associated with the use of hydraulic building hoists in construction.

- <p>Hydraulic building hoists offer several advantages, including high lifting capacity, smooth and controlled lifting, and lower maintenance costs due to fewer moving parts. They are also energy-efficient and can be easily integrated into existing systems. However, they have some disadvantages. For instance, they can be more expensive to purchase initially compared to other hoist types. Additionally, they may require more space for installation and can be sensitive to extreme temperatures, which might affect performance. Lastly, hydraulic systems can be prone to leaks and require regular fluid checks and maintenance to prevent system failure.</p>

- Q: This question asks for the steps or methods to change the height at which a building hoist operates.

- <p>To adjust the height of a building hoist, follow these steps: Ensure the hoist is powered off and unplugged. Locate the height adjustment mechanism, which is typically a set of bolts or a telescoping system. Loosen any locking nuts or bolts to allow movement. Adjust the hoist height by raising or lowering the platform to the desired level. Once the correct height is reached, tighten the nuts or bolts to secure the hoist in place. Test the hoist to ensure it operates safely at the new height. Always refer to the manufacturer's instructions for specific details on your hoist model.</p>

- Q: Is it possible to utilize a building hoist for elevating materials to a significant height for stacking purposes?

- <p>Yes, a building hoist can be used for lifting materials that need to be stacked high. These hoists are specifically designed for construction sites to lift heavy materials vertically to different levels. They are equipped with safety features to ensure materials are lifted and stacked securely and efficiently. However, the height to which materials can be stacked will depend on the hoist's lifting capacity and the specific construction site's requirements. It's crucial to follow the manufacturer's guidelines and safety regulations when operating a building hoist to prevent accidents.</p>

- Q: This question asks if a building hoist can be utilized to lift various types of materials including wood, steel, and concrete.

- <p>Yes, building hoists are designed to lift a variety of materials. They are commonly used in construction to transport materials such as wood, steel, and concrete between different floors. However, it's important to ensure that the hoist is appropriately rated for the weight of the materials being lifted and that safety protocols are followed. Each material may require specific handling techniques or attachments to secure the load properly and prevent damage or accidents.</p>

- Q: Is the construction elevator a special equipment

- The construction elevator is special equipment, the installation and demolition of the special construction plan, after the installation, the special equipment can be tested and qualified for use

- Q: Explain the key differences between electric and hydraulic lifting equipment, including their power sources, efficiency, and applications.

- <p>Electric lifting equipment is powered by electric motors and typically operates through cables or batteries, making them quieter and more environmentally friendly. They are often used in indoor settings where noise and emissions are a concern. Hydraulic lifting equipment, on the other hand, uses hydraulic fluid and pistons to generate force, providing high power and torque. They are commonly used in heavy-duty applications and outdoors. Electric systems are generally more energy-efficient and have lower maintenance costs, while hydraulic systems offer greater power density and can handle heavier loads.</p>

- Q: Is it possible for a hydraulic cylinder in a building hoist to be serviced or replaced by individuals other than the manufacturer?

- <p>Yes, a hydraulic cylinder in a building hoist can be repaired or replaced by qualified individuals or companies other than the manufacturer. However, it is crucial to ensure that the service provider has the necessary expertise and follows the manufacturer's specifications to maintain safety and performance standards. Using non-genuine parts or improper installation can lead to safety hazards and void warranties. It is always recommended to consult with professionals who are familiar with the specific hoist model and have experience in hydraulic systems repair and maintenance.</p>

- Q: What types of materials can be transported using a building hoist?

- <p>A building hoist can lift a variety of materials, including construction supplies such as bricks, cement, sand, and gravel. It can also transport larger items like steel beams, prefabricated concrete elements, and heavy machinery. Additionally, it is used to move tools, equipment, and sometimes personnel within the construction site. The specific materials that can be lifted depend on the hoist's capacity and the safety regulations in place. It's crucial to ensure that the load does not exceed the hoist's weight limit to maintain safety standards.</p>

- Q: This question asks about the safety mechanisms or features that are included in a hydraulic building hoist to ensure its secure operation.

- <p>Hydraulic building hoists are equipped with several safety features to ensure secure operation. These include overload protection to prevent the hoist from lifting more weight than it is designed for, emergency stop buttons for immediate cessation of operations, safety hooks or shackles to secure the load, and lower limit switches to prevent over-lowering. Additionally, they often have a fail-safe valve system that locks the hoist in place if pressure is lost, and a cage or gate to protect operators from falling objects. Regular maintenance and inspection are also crucial for maintaining the safety of these hoists.</p>

Send your message to us

SCD300 Single Cage/Twin Cage 3t Building Lift with Counter Weight

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords