Construction Hoist SC120 No Counterweight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

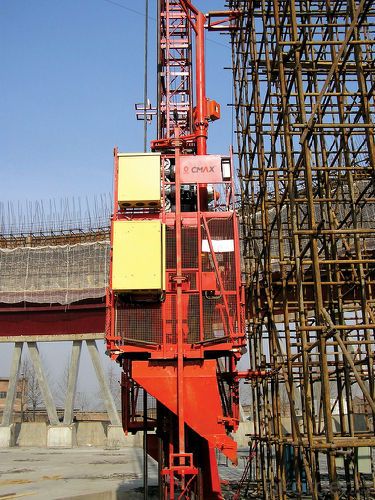

Structure of Construction Hoist Description

1.Feature: Construction Hoist

2.Payload(kg):1200

3.Lifting Speed(m/min):33

4.Motor Power(kw): 2*11

5.Safety Device: SAJ30-1.2

6.Cage: Single

7.Counterweight: No

8.Certification: CE,ISO

9.Place of Origin: China(Mainland)

10.Model Number: Type:SC120

Packaging & Delivery of Construction Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Construction Hoist

1.Main construction parts like standard sections, driving cabs are produced in mould.

2.A coat of primer is made over the bare surface before the main painting. This improves the anti-dust ability and ensure longer service life.

3.Material of standard section is 16M steel and gear rack is galvanized. The welding technology is advanced. The connection error of standard sections is very little.

4.Painting of cab, electrical device box is made after acid cleaning and parkerising, to ensure a long usage life.

5.Driving plate, transmission bracket is of floating connection, which has reduced the vibration and noise effectively.

6.A complete, reliable chain of electric and mechanical safety devices: Door safety switch, breaking-rope protection switch, upper and lower limit switches, limit switches and other electromechanical interlock switches, the overall forging style security protection hook, advanced progressive anti-dropping safety device , odd and even outside-cage, electric lock, emergency stop switches, overload protection devices, as well as the bottom of the buffer and so on. Safety performance meets international advanced standards.

7.Each elevator goes through strict test run before delivery.

Construction Hoist Specifiction

Single cage High speed

Model | Speed(m/min) | Deadweight(kg) | Motor(KW) | Counterweight | Specification(L×W×H)(m) |

SC100G | 96 | 1000 | 3×22 | No | 2.5×1.3×2.5 |

SC120G | 96 | 1200 | 3×22 | NO | 3.0×1.3×2.5 |

SCD200G | 96 | 2000 | 3×15 | Have | 3.2×1.5×2.5 |

SC200G | 96 | 2250 | 3×22 | No | 3.2×1.5×2.5 |

SC270GS | 96 | 2700 | 3×22 | No | 3.8×1.5×2.5 |

SCD270G | 96 | 2700 | 3×18.5 | Have | 3.8×1.5×2.5 |

SCD300G | 96 | 3000 | 3×22 | Have | 4.0×1.5×2.5 |

SCD320GS | 96 | 3200 | 3×22 | Have | 4.2×1.5×2.5 |

Single cage Medium speed

SC100GZ | 63 | 1000 | 3×15 | No | 2.5×1.3×2.5 |

SC120GZ | 63 | 1200 | 3×15 | No | 3.0×1.3×2.5 |

SCD200GZ | 63 | 2000 | 2×15 | Have | 3.0×1.3×2.5 |

SC200GZ | 63 | 2000 | 3×18.5 | No | 3.0×1.3×2.5 |

SC225GZ | 63 | 2250 | 2×18.5 | No | 3.2×1.5×2.5 |

SC225GZ | 63 | 2250 | 3×18.5 | Have | 3.6×1.5×2.5 |

SCD250GZ | 63 | 2500 | 2×18.5 | Have | 3.6×1.5×2.5 |

SC250GZ | 63 | 2500 | 3×18.5 | Have | 3.8×1.5×2.5 |

SCD270GZ | 63 | 2700 | 2×18.5 | Have | 3.8×1.5×2.5 |

SC270GZ | 63 | 2700 | 3×22 | NO | 4.0×1.5×2.5 |

SCD300GZ | 63 | 3000 | 3×15 | Have | 4.0×1.5×2.5 |

SCD320GZ | 63 | 3200 | 3×15 | Have | 4.2×1.5×2.5 |

Single cage standard speed

SC100TD | 36 | 1000 | 2×11 | NO | 2.5×1.3×2.5 |

SC120TD | 36 | 1200 | 2×11 | NO | 3.0×1.3×2.5 |

SC200TD | 36 | 2000 | 3×11 | NO | 3.0×1.3×2.5 |

SCD200TD | 36 | 2000 | 2×11 | Have | 3.2×1.5×2.5 |

SC270TD | 36 | 2700 | 3×15 | NO | 3.6×1.5×2.5 |

SCD270TD | 36 | 2700 | 2×11 | Have | 3.8×1.5×2.5 |

SC320TD | 36 | 3200 | 3×18.5 | NO | 4.0×1.5×2.5 |

SCD320TD | 36 | 3200 | 2×11 | Have | 4.2×1.5×2.5 |

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Explain the distinctions between electric and manual building hoists, focusing on their operation, efficiency, and use cases.

- <p>Electric building hoists are powered by electricity and offer faster operation, greater efficiency, and the ability to lift heavier loads. They are ideal for large-scale construction projects where rapid movement of materials is necessary. In contrast, manual hoists are operated by hand and are typically smaller, more portable, and require human effort to lift materials. They are suitable for smaller projects or where power supply is limited. Electric hoists are more automated and can be controlled remotely, while manual hoists require constant physical effort and are less efficient in terms of speed and load capacity.</p>

- Q: Is it possible to utilize a building hoist for the purpose of lifting small objects?

- <p>Yes, a building hoist can be used for lifting small objects, provided it is safe and the hoist is designed for such loads. Building hoists are typically engineered to handle heavy construction materials, but they can be adapted for smaller loads with proper rigging and safety measures. It's crucial to ensure the weight of the object does not exceed the hoist's capacity and that the hoist is operated by trained personnel following safety protocols to prevent accidents.</p>

- Q: This question asks for the steps or process involved in installing a building hoist, which is a type of crane used in construction to lift materials.

- <p>Installing a building hoist involves several steps: 1) Site preparation, ensuring the ground is level and strong enough to support the hoist. 2) Assembling the hoist tower, starting from the base and working upwards. 3) Installing the motor and drive system. 4) Attaching the cable and counterweight. 5) Rigging the hoist with safety devices and load limiters. 6) Conducting a thorough inspection and testing the hoist for safety and functionality. 7) Obtaining any necessary permits and approvals. It's crucial to follow the manufacturer's instructions and local regulations, and often requires a professional team for safe and proper installation.</p>

- Q: This question asks about the method to determine the maximum weight a building hoist can safely support.

- <p>Calculating the maximum load capacity of a building hoist involves several factors. First, consider the hoist's mechanical design and the manufacturer's specifications, which provide the rated load capacity. This is the maximum weight the hoist is designed to handle. Next, assess the condition of the hoist, as wear and tear can reduce its capacity. Additionally, consider the strength of the supporting structure and the safety factor, which is typically a multiplier of the rated load capacity to ensure safety. For example, if the hoist is rated for 1000 kg, a safety factor of 1.5 means the actual maximum load should not exceed 667 kg (1000 kg / 1.5). Always consult with engineers and follow local regulations and standards for precise calculations.</p>

- Q: This question asks about the time required to install a building hoist, a device used for lifting materials in construction.

- <p>The time it takes to install a building hoist can vary significantly based on factors such as the type and size of the hoist, the specific building requirements, and the experience of the installation team. On average, it can take anywhere from a few hours to a couple of days. For smaller hoists, installation might be completed within a day, while larger, more complex systems could take longer. It's important to note that safety checks and regulatory compliance verifications are also part of the process, which can add to the total installation time.</p>

- Q: What types of materials can be transported using a building hoist?

- <p>A building hoist can lift a variety of materials, including construction supplies such as bricks, cement, sand, and gravel. It can also transport larger items like steel beams, prefabricated concrete elements, and heavy machinery. Additionally, it is used to move tools, equipment, and sometimes personnel within the construction site. The specific materials that can be lifted depend on the hoist's capacity and the safety regulations in place. It's crucial to ensure that the load does not exceed the hoist's weight limit to maintain safety standards.</p>

- Q: This question asks whether a building hoist can be utilized to lift various objects with differing weights and dimensions.

- <p>Yes, building hoists are designed to lift a variety of objects with different weights and sizes. They are versatile and adjustable, allowing for the transportation of materials such as bricks, concrete, and equipment. However, each hoist has a specific weight capacity that must not be exceeded. It's crucial to ensure that the objects being lifted are within the hoist's capacity and that the hoist is properly configured for the size and shape of the objects to ensure safety and efficiency.</p>

- Q: Whether the construction elevator is a dual-purpose elevator

- Very simple check, the construction elevator is in the construction site, not completely closed, and the human cargo is used commonly in the mall and the factory, is completely closed.

- Q: How many meters is the wall of the construction elevator?

- I know the bunter lift is six meters so you can get it

- Q: This question asks for a description of the process of using a hydraulic cylinder in the context of a building hoist.

- <p>To use a hydraulic cylinder in a building hoist, first ensure the hoist is properly installed and secured. Connect the hydraulic cylinder to the hoist's power source, typically a hydraulic pump. The pump pressurizes hydraulic fluid, which is then directed into the cylinder. As the fluid enters, it pushes a piston within the cylinder, causing it to extend and lift the load. To lower the load, the fluid is released from the cylinder, allowing the piston to retract. Always monitor the pressure and ensure the system is leak-free for safe operation. Regular maintenance, including checking seals and lubricating parts, is crucial to prolong the life of the hydraulic cylinder and ensure efficient hoist performance.</p>

Send your message to us

Construction Hoist SC120 No Counterweight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords