Building Hoist SCD250 Counterweight Single Cage

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist Description

Feature: Building Hoist Condition: New Application: Construction

Payload(kg):2500 Lifting Speed(m/min):0~60 Motor Power(kw): 2*18.5

Safety Device: SAJ50-1.4 Cage: Single Counterweight: Yes

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: Type:SCD250

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Features of Building Hoist

● Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

● The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake

and prolongs the spare parts'life.

● The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

● The system applies the special software for hoists developed by our company, making the operation more safe and

reliable.

Building Hoist Images

CMAX Building Hoist

Anchorage System

Mast Section

Driving Unit

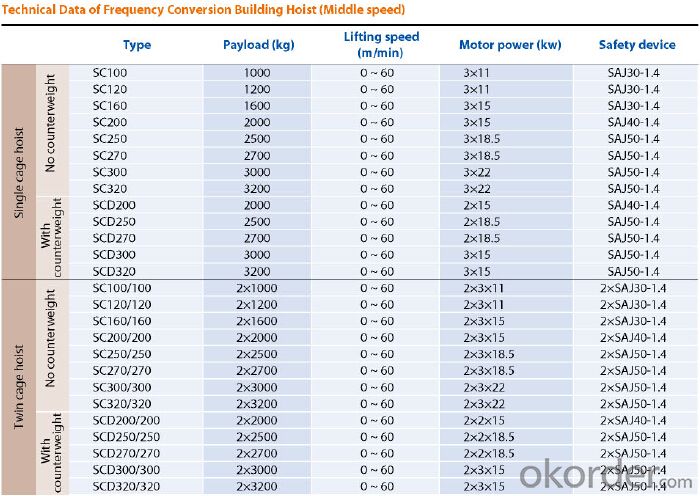

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: What are the requirements for the construction elevator

- The anti-drop safety device is an important part of the construction elevator, which can be relied on to eliminate the occurrence of the fall accident and guarantee the safety of the crew. So for safety device factory test is very strict, before delivery by the statutory inspection unit for torque measurement, critical speed measurement, measuring the amount of spring compression, each with the test report, after assembly to the construction lifter for drop test under rated load, and the site to use the elevator must be every three months to conduct a drop test. For safety device to the factory for two years for safety device (delivery date), must also be sent to the statutory inspection unit to carry on the test, after testing once a year. So far few inspection, some sites even once every three months to detect don't do drop test, all think that their is no problem for safety device, but once had an accident, repent at leisure. Why not do regular tests and tests? The use of units blindly thinks that not bad is good. Actually good or bad for safety device can only judge by test and inspection in the daily operation is not sure whether it is good or bad, for those who are serving for safety device, or advice for the earlier inspection and regular test, only accomplish know fairly well, to malignant accident prevention rather than cure.

- Q: This question asks for methods to protect lifting equipment from damage while it is being transported or stored.

- <p>To prevent damage to lifting equipment during transportation or storage, follow these guidelines: 1. Use protective covers or wraps to shield equipment from environmental elements. 2. Securely fasten equipment to prevent movement during transit. 3. Store equipment in a dry, clean area to avoid rust and dirt accumulation. 4. Regularly inspect equipment for signs of wear or damage before and after use. 5. Follow the manufacturer's guidelines for weight limits and proper handling. 6. Use padding or cushioning materials to protect equipment from impacts. 7. Ensure that all parts are properly lubricated to prevent rust and facilitate smooth operation. By adhering to these practices, you can significantly reduce the risk of damage to lifting equipment.</p>

- Q: Is it possible to use a building hoist to lift various materials simultaneously?

- <p>Yes, a building hoist can be used for lifting multiple materials at once, provided the total weight does not exceed the hoist's load capacity. It's crucial to ensure that the materials are securely fastened and balanced to prevent tipping or damage. Always follow the manufacturer's guidelines and safety regulations to avoid accidents and ensure the safe operation of the hoist.</p>

- Q: This question asks for an explanation of the different types of building hoists used in construction.

- <p>Building hoists, also known as construction hoists or material hoists, are essential for moving materials and personnel in high-rise construction projects. The main types include: 1. <strong>Freestanding Hoists</strong>: These do not require a building structure for support and are self-supporting. 2. <strong>Cladding Hoists</strong>: Attached to the building's facade, used for moving materials during cladding work. 3. <strong>Personnel Hoists</strong>: Specifically designed for transporting workers, ensuring safety with features like cages and safety devices. 4. <strong>Material Hoists</strong>: Built to transport heavy construction materials and are robust and durable. 5. <strong>Electric Hoists</strong>: Operated by electricity, offering precise control and energy efficiency. 6. <strong>Hydraulic Hoists</strong>: Utilize hydraulic systems for lifting, known for their smooth operation and heavy load capacity. Each type serves a specific purpose and is chosen based on the project's requirements and the stage of construction.</p>

- Q: Is it feasible to repair or replace a building hoist with ease?

- <p>The ease of repairing or replacing a building hoist depends on several factors. For minor issues, repairs can often be done relatively easily by trained technicians. However, for major malfunctions or when a hoist is outdated, replacement might be necessary. This process can be complex and requires expertise to ensure safety and compliance with building codes. Factors such as the hoist's age, the complexity of the system, and the availability of replacement parts play a significant role in determining the ease of repair or replacement. In some cases, it might be more cost-effective to replace rather than repair, especially if the hoist is old or if repair costs are high.</p>

- Q: What specific regulations or conditions must be met when utilizing lifting equipment in construction or factory environments?

- <p>Yes, there are special requirements for using lifting equipment in construction sites and factories. These include adherence to safety regulations, regular maintenance and inspection, proper operator training, and ensuring the equipment is suitable for the task. Compliance with local and national laws such as OSHA in the U.S. or CE marking in the EU is crucial. Equipment must be certified safe for use, and operators must be licensed and follow safety protocols. Additionally, load capacities must be respected, and lifting operations must be planned and supervised to prevent accidents.</p>

- Q: Identify the elements that influence the durability and operational lifespan of lifting machinery, specifically focusing on Building Hoists.

- <p>The lifespan of lifting equipment, including Building Hoists, is influenced by several factors: 1) Material Quality: The type and quality of materials used in construction directly affect durability and resistance to wear and tear. 2) Design and Engineering: Proper design ensures optimal performance and reduces stress on components. 3) Frequency of Use: More frequent use can lead to faster wear and tear. 4) Maintenance and Repair: Regular maintenance can extend the lifespan, while neglect can shorten it. 5) Operating Conditions: Environmental factors such as temperature, humidity, and exposure to corrosive substances can impact longevity. 6) Load Capacity: Overloading can cause premature failure. 7) Compliance with Safety Standards: Adhering to safety guidelines can prevent accidents and damage. 8) Technological Advancements: Newer models may have improved features that extend lifespan.</p>

- Q: This question asks for an explanation on how to operate an automatic control system for a building hoist.

- <p>To use an automatic control system for a building hoist, first ensure the system is properly installed and inspected. Familiarize yourself with the control panel, which typically includes buttons for up, down, stop, and emergency stop. Ensure all safety protocols are in place. Turn on the system and select the desired hoist. Use the up and down buttons to control the hoist's movement. Monitor the load and adjust the speed as needed. Always be aware of the hoist's limits and never exceed them. Regularly check the system for any faults or irregularities and address them promptly. Remember, safety is paramount when operating a building hoist.</p>

- Q: What precautions should be taken on construction sites when operating a building hoist?

- <p>Safety measures for using a building hoist in construction sites include regular inspections and maintenance to ensure the hoist is in good working condition. Operators must be trained and certified to use the hoist. Safety barriers or gates should be installed to prevent unauthorized access. Load limits must be strictly adhered to, and overloading is prohibited. Emergency stop buttons should be easily accessible. Workers should wear appropriate personal protective equipment (PPE). Regular safety briefings and training sessions should be conducted to keep workers informed about safe hoist operation procedures.</p>

- Q: Is it possible for a building hoist to experience malfunctions that lead to damage?

- <p>Yes, a building hoist can malfunction and cause damage. Malfunctions can occur due to various reasons such as mechanical failure, operator error, or poor maintenance. These malfunctions can lead to accidents, including dropped loads, structural damage, or even injuries to workers. Regular inspections, proper maintenance, and adherence to safety protocols are crucial to minimize the risk of hoist malfunctions in construction settings.</p>

Send your message to us

Building Hoist SCD250 Counterweight Single Cage

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords