Scaffolding And Steel Prop

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Type: | Scaffolding Part Type: |

| Usage: | Main Material: | Surface Finish: | |||

| Length: | German Type OD: | Italian Type OD: | |||

| Spanish Type OD: | Regular Thickness: | Popular Color: |

Packaging & Delivery

| Delivery Detail: | 20~25days after receiving your deposit or L/C |

Specifications

1.alibaba China manufacturers Scaffolding Steel Prop

2.original manufacturer,

3.Certificate:BV

4.OEM service

| Regular Specification & Measurement | ||||

| Description | Length | External Tube | Inner Tube | Weight |

| Spanish Props | 0.8-1.4m | 48*1.6*600mm | 40*1.6*800mm | 4.86kg |

| 1.6-3.0m | 48*1.6*1400mm | 40*1.6*1600mm | 7.54kg | |

| 2.0-3.5m | 48*1.8*1500mm | 40*1.8*2000mm | 9.02kg | |

| 2.2-4.0m | 48*2.0*1800mm | 40*2.0*2200mm | 10.76kg | |

| Italian Props | 1.6-2.9m | 56*1.6*1300mm | 48*1.6*1600mm | 8.27kg |

| 1.8-3.1m | 56*1.8*1300mm | 48*1.8*1800mm | 9.37kg | |

| 2.0-3.6m | 56*2.0*1600mm | 48*2.0*2000mm | 11.35kg | |

| 2.2-4.0m | 56*2.2*1800mm | 48*2.2*2200mm | 13.27kg | |

| German Props | 1.6-2.7m | 60*2.0*1100mm | 48*2.0*1600mm | 9.23kg |

| 2.0-3.5m | 60*2.5*1500mm | 48*2.5*2000mm | 13.38kg | |

| 2.2-4.0m | 60*3.0*1800mm | 48*3.0*2200mm | 17.36kg | |

| 3.0-5.5m | 60*3.2*2500mm | 48*3.2*3000mm | 24.26kg | |

| The length and thickness also could cater to customer orders. | ||||

- Q: Are steel props adjustable in small increments for precise leveling?

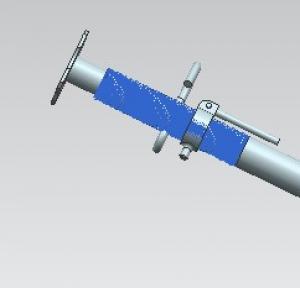

- Steel props have the ability to be adjusted in small increments, allowing for precise leveling. They are commonly used in construction projects to provide temporary support and stability to beams, walls, and ceilings. These props, also known as adjustable steel props or scaffolding props, consist of two main components - an outer tube and an inner tube. The inner tube can be adjusted to different heights, enabling the supported structure to be leveled accurately. The adjustment process involves rotating a threaded collar on the outer tube, resulting in the inner tube moving up or down in small increments. This adjustability feature makes steel props an exceptional choice for achieving exact and precise leveling in construction projects.

- Q: How are steel props secured in place?

- Adjustable steel props, known as steel props or acrow props, are widely used in construction to temporarily support structures or formwork. These props are fastened using a simple yet effective method. To begin, the steel props are positioned vertically, with one end resting on a solid surface like the ground or a concrete slab. The other end of the prop is then adjusted to the desired height by extending or retracting the inner tube within the outer tube of the prop. This allows for flexibility in adjusting the prop to meet the specific requirements of the construction site. Once the desired height is set, it is necessary to secure the prop in place to ensure stability and prevent any movement. Typically, this is accomplished by employing a pin or locking mechanism situated at the collar of the prop. The pin is inserted into pre-drilled holes on the outer tube, which locks the inner and outer tubes together, preventing any further movement or adjustment. Furthermore, to enhance stability and prevent sideways movement, steel props can be braced or tied to adjacent structures or beams using appropriate accessories like steel tubes, clamps, or tie rods. These braces are usually attached to the collar of the prop and then secured to nearby structures or beams, forming a rigid and stable support system. Overall, steel props are secured in place by adjusting their height, locking the inner and outer tubes together using a pin or locking mechanism, and optionally bracing or tying them to adjacent structures. This ensures that the props remain firmly in position, offering reliable support during construction activities.

- Q: Can steel props be used in warehouse construction?

- Warehouse construction can utilize steel props. These props, also known as adjustable steel props or scaffolding props, are commonly employed in construction endeavors to uphold vertical loads. They serve as temporary support during the construction process, particularly for formwork and scaffolding. In the context of warehouse construction, steel props can be employed to uphold hefty loads like roof beams, columns, and walls. They prove particularly useful in situations where supplementary support is necessary to guarantee the stability of the structure. Steel props can be conveniently adjusted to the desired height and can be used in various configurations to cater to the specific demands of the warehouse construction project. Furthermore, steel props present numerous advantages over alternative support systems. They possess the attributes of being lightweight, durable, and capable of enduring substantial loads. Additionally, they are versatile and can be effortlessly installed and disassembled, rendering them a cost-effective solution for provisional support in warehouse construction. Ultimately, steel props constitute a dependable and efficient choice for sustaining heavy loads in warehouse construction. Nonetheless, it is imperative to consult with a structural engineer or construction professional to ensure the proper and safe utilization of the props, in accordance with the project's distinct requirements.

- Q: Are steel props suitable for use in confined spaces?

- In confined spaces, steel props are generally unsuitable due to limited ventilation, restricted access, and potential presence of hazardous gases or substances. Maneuvering heavy steel props in tight spaces can be dangerous. Moreover, the size and weight limitations of steel props may result in insufficient support. Therefore, it is crucial to opt for props specifically designed for confined spaces. Adjustable aluminum or hydraulic props are lightweight, portable, and meet the safety requirements of these environments.

- Q: How do you prevent steel props from sinking into soft ground?

- There are several measures that can be taken to prevent steel props from sinking into soft ground. These include: 1. Opt for larger steel plates: Placing larger steel plates beneath the props helps distribute the weight over a larger area, reducing the risk of sinking. The size of the plates should be selected based on the load and soil conditions. 2. Incorporate timber sole boards: Adding timber sole boards beneath the props further distributes the weight, lessening the pressure on the soft ground. The boards should be of sufficient thickness to provide adequate support and prevent sinking. 3. Implement ground improvement techniques: Strengthening soft ground can be achieved through various techniques such as soil compaction, soil stabilization, or the installation of geotextiles. These methods enhance the soil's load-bearing capacity, making it more resistant to sinking. 4. Install ground reinforcement: Utilizing ground reinforcement methods like geogrids or geosynthetic materials helps stabilize the soil and prevent sinking. These materials can be placed beneath the props to offer additional support and distribute the load. 5. Explore alternative support systems: In certain cases, it may be more suitable to utilize alternative support systems that are specifically designed for soft ground conditions. Examples include helical piles, micropiles, or ground screws, which provide enhanced stability in challenging soil conditions. To ensure the appropriate solution for preventing steel props from sinking into soft ground, it is crucial to assess the specific site conditions and consult with engineering professionals.

- Q: How long does a steel prop typically last?

- The lifespan of a steel prop typically depends on various factors such as the quality of the prop, the load it is subjected to, and the frequency of use. However, on average, a steel prop can last anywhere between 5 to 10 years. Regular maintenance and adherence to the manufacturer's guidelines can also significantly extend the prop's lifespan. It is essential to inspect the prop for any signs of wear and tear, such as rust, cracks, or deformation, and replace it promptly if necessary.

- Q: What is the difference between these two kinds of construction? Why do I see the fixed steel support only the width difference, its length is fixed?

- Row pile support, pile support, pile anchor, row pile cantileverThe underground continuous wall support wall + support;3 cement soil retaining wall;3: steel sheet pile supporting transverse baffle pile, steel sheet pile support;

- Q: Are steel props suitable for supporting temporary stages or platforms?

- Yes, steel props are suitable for supporting temporary stages or platforms. Steel props, also known as steel acrow props, are adjustable telescopic supports made from high-quality steel. They are commonly used in construction and scaffolding projects to provide temporary support and stability. Steel props are ideal for supporting temporary stages or platforms due to their strength and durability. They can bear heavy loads and provide a sturdy base for platforms or stages, ensuring the safety of performers and attendees. The adjustable feature of steel props allows for easy customization of height, making them suitable for various stage or platform designs. Additionally, steel props are easy to install and dismantle, making them practical for temporary setups. They can be quickly adjusted and secured in place, providing a reliable support system for stages or platforms. Their robust construction ensures stability and minimizes the risk of accidents or collapses during performances or events. In summary, steel props are a suitable choice for supporting temporary stages or platforms. Their strength, adjustability, and ease of installation make them a reliable and safe support system for various event setups.

- Q: Are steel props suitable for temporary structures?

- Yes, steel props are suitable for temporary structures. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction projects to support temporary structures such as formwork, scaffolding, and shoring systems. They are designed to provide stability and load-bearing capacity, making them ideal for supporting structures during construction, renovation, or repairs. Steel props are adjustable in height, allowing them to accommodate different structures and provide precise support. They are made from high-quality steel, which ensures their durability and strength. This makes them capable of supporting heavy loads and providing a reliable temporary support system. Additionally, steel props are easy to install and dismantle, making them highly efficient for temporary structures. They can be quickly adjusted to the desired height and can be easily removed once the temporary structure is no longer required. This flexibility and ease of use make steel props a popular choice in the construction industry for temporary structures. However, it is important to note that the suitability of steel props for temporary structures depends on various factors such as the size and weight of the structure, the duration of use, and the specific requirements of the project. It is always recommended to consult with a structural engineer or construction professional to ensure the appropriate selection and usage of steel props for temporary structures.

- Q: Are steel props suitable for supporting temporary walkways or catwalks?

- Yes, steel props are suitable for supporting temporary walkways or catwalks. Steel props are sturdy, adjustable, and capable of bearing heavy loads, making them an ideal choice for providing reliable support and stability for temporary structures like walkways or catwalks.

Send your message to us

Scaffolding And Steel Prop

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords