Sac Géotextile Polypropylene Filter Non-Woven Geotextile Fabric for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

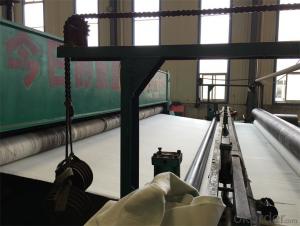

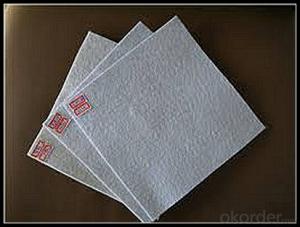

Nonwoven Geotextile 600G/M2 Geotextile Pp Non-Woven Geotextile Bags Made In China is a special kind of nonwoven geotextile because of its special manufacture method by puncturing the rolling formed layer made of randomly oriented short staple fiber. Our raw material is the top class 100% new PP(Polyproplylene) or PET(Polyester) fiber. The needle punch process involves forcibly entangling layers of loose staple fibre into three dimensional structure by sequentially punching and pulling out barbed needles through the fiber matrix, and forms a strong fabric that retains its dimensional stability, expands the serving year to all the applied project. Because of its proven track record and versatility, Needle Punched, as the most commonly used Nonwoven Geotextile, is widely used in civil and environmental engineering applications like subsurface drainage, roadway separation, railroad stabilization, erosion control, hard armor underlayment, landfill leachate collection, underground retention/detention systems, environmental protection and other projects.

Non Woven Geotextile Product Show:

Main Export Markets:

Asia

Australasia

Central/South America

Eastern Europe

Mid East/Africa

North America

Western Europe

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: The difference between lap and stitching

- Power and load are angular and star connection. When the power supply is connected, the phase voltage of the power supply is equal to the line voltage. The line voltage of the star load is equal to the line voltage of the power supply. The phase voltage of the load is equal to the line voltage divided by the root number. When the power supply is connected, the line voltage of the power supply is equal to three times the root number of the power supply phase voltage. The line voltage of the corner load is equal to the line voltage of the power supply, and the phase voltage is equal to the line voltage. Both at the same time using the corner, the load line voltage is equal to the power line voltage, phase voltage is equal to the line voltage. At the same time using the star, the load line voltage is equal to the power line voltage, the load phase voltage is equal to the power phase voltage, phase voltage equal to the line voltage divided by the root number three.

- Q: How are geotextiles made?

- Geotextiles are made by weaving or knitting synthetic fibers together to create a strong, durable fabric that can be used for various geotechnical applications.

- Q: Can geotextiles be used for soil stabilization?

- Yes, geotextiles can be used for soil stabilization. They are commonly used in civil engineering projects to reinforce soils, prevent erosion, and improve the overall stability of the soil. Geotextiles can effectively distribute loads, control soil movement, and enhance the performance of the soil in various applications such as road construction, retaining walls, slopes, and landfills.

- Q: Detailing the geotextile standard which, how to apply their own

- GB GB I specialize in the production of geotechnical materials

- Q: Are geotextiles effective in preventing weed growth?

- Yes, geotextiles are effective in preventing weed growth. They act as a physical barrier that inhibits weed growth by blocking sunlight and preventing weed seeds from germinating. Additionally, geotextiles allow for water and air permeability, ensuring proper drainage while still suppressing weed growth.

- Q: How do geotextiles enhance the performance of retaining walls?

- Geotextiles enhance the performance of retaining walls by providing reinforcement and stability to the structure. They act as a barrier against soil erosion and prevent the loss of fine particles, thus improving the overall durability and strength of the retaining wall. Additionally, geotextiles help in the efficient drainage of water, reducing hydrostatic pressure and preventing the buildup of excess moisture behind the wall, which can compromise its structural integrity.

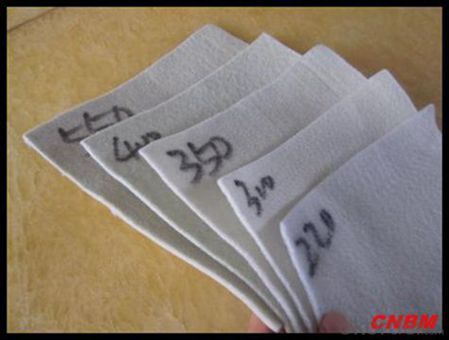

- Q: U400 geotextile u400 what it means

- Is not 400g / ㎡ of geotextile? My company specializes in the production of geotextiles, details (hand) to see capital (machine) material

- Q: How do geotextiles improve the performance of embankments?

- Geotextiles improve the performance of embankments by providing reinforcement and stabilization. They distribute loads more evenly, preventing the embankment from settling or shifting. Additionally, geotextiles control erosion by allowing water to flow through while retaining soil particles, reducing the risk of slope failure.

- Q: How do geotextiles help in reducing the risk of slope failures?

- Geotextiles help in reducing the risk of slope failures by providing reinforcement and stabilization to the soil. They are used to reinforce the soil layers, prevent erosion, and improve drainage, thereby enhancing the overall stability of the slope.

- Q: JTGF80 / 1-2004 "standard" 4.5 Geosynthetics in the treatment of the measured items in the "anchoring length", in the construction design diagram, the provisions of the value of the allowable deviation should be how to implement? Question added: Sorry! I missed a few words. When the construction design is not indicated, the specified value, the allowable deviation value should be implemented? JTGF80 / 1-2004 "standard only write to meet the design, construction requirements. I did not say that the design of the length of the anchorage is how much, can not find the construction technical specifications. So I do not know the provisions of the value of how to allow deviation? More

- Specifically not less than the specified value, does not exceed the allowable deviation. This is the so-called construction by specification! You refer to JTG assessment standard -2004 is correct! I have the data to let you refer to the next / geogrid and geotextile landscape is greater than or equal to 50cm, vertical is greater than or equal to 150com

Send your message to us

Sac Géotextile Polypropylene Filter Non-Woven Geotextile Fabric for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords