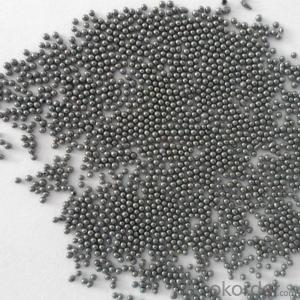

S70-S780 Steel Shot with ISO9001 & SAE Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Product Description:

1.18 years on metal abrasives manufacturing and exporting.

2. Delivery within 15 days.

3. Full transport insurance.

4. Sell to 32 countries on 5 continents.

Product Picture:

Size:

S780, S660, S550, S460, S390, S330, S280, S230, S170, S110, S70

Chemistry Composition:

| C | Mn | Si | S | P |

| 0.70-1.20% | 0.60-1.20% | 0.40-1.20% | ≤0.05% | ≤0.05% |

Average degree of hardness:

| Normal | 40-50HRC (377-509HV) |

| Special | 52-56HRC (543-620HV) |

| Special | 56-60HRC (620-713HV) |

| Minimum density | 7.4g/cm3 |

Package:

25kgs/bag, 40bags/ton/pallet

1000kgs/ton bag

Product Standard:

American automobile engineer's association "SAE J827Cast steel shot standard"

Product use:

Cast steel shot is wildly used for cleaning the rust of metal surface and the reinforced of metal parts. Such as Foundry Industry, Shipbuilding Industry, Container Industry, Marble Cutting, Petroleum Pipeline, Automotive Industry etc.

| Cast Steel Shot Grain the degree distribute | ||||||||||||

| The eyes count | mm | sizes | ||||||||||

| 2.5 | 2.0 | 1.7 | 1.4 | 1.2 | 1.0 | 0.8 | 0.6 | 0.5 | 0.3 | 0.2 | ||

| 7 | 2.80 | all pass | ||||||||||

| 8 | 2.36 | all pass | ||||||||||

| 10 | 2.00 | 85% min | all pass | all pass | ||||||||

| 12 | 1.70 | 97% min | 85% min | 5% max | all pass | |||||||

| 14 | 1.40 | 97% min | 85% min | 5% max | all pass | |||||||

| 16 | 1.18 | 97% min | 85% min | 5% max | all pass | |||||||

| 18 | 1.00 | 96% min | 85% min | 5% max | all pass | |||||||

| 20 | 0.850 | 96% min | 85% min | 10% max | all pass | |||||||

| 25 | 0.710 | 96% min | 85% min | 10% max | ||||||||

| 30 | 0.600 | 96% min | 85% min | all pass | ||||||||

| 35 | 0.500 | 97% min | 85% min | 10% max | ||||||||

| 40 | 0.425 | 97% min | all pass | |||||||||

| 45 | 0.355 | 80% min | 10% max | |||||||||

| 50 | 0.300 | 90% min | ||||||||||

| 80 | 0.180 | 80% min | ||||||||||

| 120 | 0.125 | 90% min | ||||||||||

| 200 | 0.075 | |||||||||||

| 325 | 0.045 | |||||||||||

| SAE Standard | S-780 | S-660 | S-550 | S-460 | S-390 | S-330 | S-280 | S-230 | S-170 | S-110 | S-70 | |

- Q: What are the different grades of steel used in construction?

- There are several different grades of steel used in construction, including mild steel, high-strength low-alloy (HSLA) steel, carbon steel, stainless steel, and structural steel. Each grade has its own unique properties and characteristics that make it suitable for specific construction applications.

- Q: What are the applications of steel angles?

- Steel angles have a wide range of applications in construction and manufacturing industries. Some common uses include providing structural support in buildings and bridges, reinforcing concrete structures, creating frameworks for machinery and equipment, as well as forming braces and brackets for various architectural and engineering projects.

- Q: How can steel products be recycled and reused?

- Steel products can be recycled and reused through a process called steel recycling. This involves collecting scrap steel from various sources, such as old cars, appliances, and construction materials, and melting it down in a furnace. The molten steel is then cast into new products, such as steel bars, beams, and sheets. This recycling process not only conserves natural resources but also reduces energy consumption and greenhouse gas emissions. Additionally, steel can be reused by refurbishing and repurposing existing steel products, such as furniture, machinery, and infrastructure, extending their lifespan and minimizing waste. Overall, steel recycling and reusing play a crucial role in promoting sustainability and circular economy practices.

- Q: How does steel sheet metal fabrication work?

- Steel sheet metal fabrication involves the process of shaping and manipulating steel sheets into desired forms and structures using various techniques such as cutting, bending, and assembling. This is typically done through the use of specialized machinery and tools, such as laser cutters, press brakes, and welders. The steel sheets are first cut into the required shape, either manually or through automated processes. Then, they are bent or formed using press brakes to achieve the desired angles or curves. Finally, the individual parts are assembled together through welding, fastening, or other joining methods, resulting in a finished steel sheet metal product.

- Q: How are steel coils used in manufacturing processes?

- Steel coils are used in manufacturing processes as a primary material for various applications such as construction, automotive, appliances, and machinery. These coils are typically unwound and processed through different machines to be shaped, cut, and formed into the desired products. The versatility and strength of steel coils make them an essential component in many manufacturing industries.

- Q: What are the advantages of using steel products in construction?

- There are several advantages of using steel products in construction. Firstly, steel is incredibly strong and durable, allowing for the construction of sturdy and long-lasting structures. Secondly, steel is a highly versatile material that can be easily manipulated and fabricated to meet specific design requirements. Additionally, steel is fire-resistant, providing a higher level of safety compared to other materials. Moreover, steel is recyclable, making it an environmentally-friendly choice. Lastly, steel structures are often cost-effective due to their efficiency in construction and maintenance, making them a popular choice in the industry.

- Q: How does steel reinforcement work in concrete structures?

- Steel reinforcement in concrete structures works by providing tensile strength to the concrete. Concrete is strong in compression but weak in tension, so the addition of steel bars or mesh within the concrete helps to resist cracking and increase its overall strength. The steel reinforcement acts as a skeleton, distributing and absorbing the tensile forces that occur due to various factors such as loads, temperature changes, and shrinkage. This combination of concrete and steel creates a composite material that is capable of withstanding greater stress and improving the durability and longevity of the concrete structure.

- Q: What are the different grades of steel used in various industries?

- There are several different grades of steel used in various industries, including carbon steel, stainless steel, alloy steel, and tool steel. Carbon steel is widely used due to its affordability and versatility, while stainless steel is known for its corrosion resistance and hygienic properties, making it suitable for industries like food processing and medical equipment. Alloy steel contains additional elements such as manganese, nickel, or chromium to enhance its strength, durability, and heat resistance. Tool steel, on the other hand, is specifically designed for tools and machinery that require high hardness and resistance to wear and deformation. Overall, the choice of steel grade depends on the specific requirements and applications of each industry.

- Q: How is steel used in the construction of power plants?

- Steel is used extensively in the construction of power plants due to its strength, durability, and high melting point. It is utilized for various components such as structural frames, support beams, turbine casings, and pressure vessels. Steel's ability to withstand high temperatures, pressures, and harsh environmental conditions makes it an ideal material for power plant infrastructure, ensuring the safety and reliability of these facilities.

- Q: What are the applications of alloy steel in the energy sector?

- Alloy steel finds various applications in the energy sector due to its exceptional mechanical properties and resistance to corrosion and high temperatures. It is commonly used in the construction of power plants, oil and gas pipelines, and nuclear reactors. Alloy steel is also utilized in the manufacturing of turbine components, such as shafts and blades, as well as in the production of drilling equipment for the exploration and extraction of oil and gas. Overall, alloy steel plays a crucial role in enhancing the efficiency, durability, and safety of energy infrastructure.

Send your message to us

S70-S780 Steel Shot with ISO9001 & SAE Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords