Rubber wood floor decking for outdoor made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

一. Structure of Rubber wood floor decking

Item | Rubber wood floor decking-- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

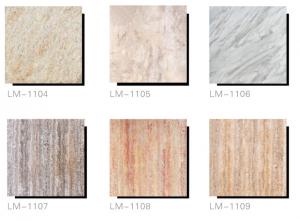

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

二.Main Features of Rubber wood floor decking

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

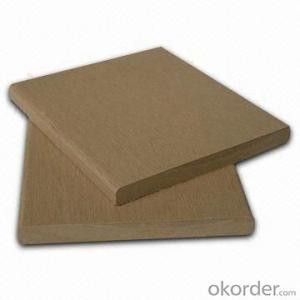

三. Picture of Rubber wood floor decking

四. Rubber wood floor decking Specification

Name | Rubber wood floor decking |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

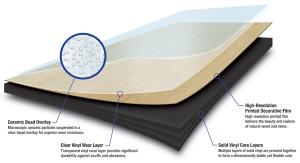

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

五.FAQ of Rubber wood floor decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: EVA plastic floor and PVC plastic floor which is good

- PVC: is stable; it is not easy to be corroded by acid and alkali.

- Q: Board PVC plastic floor plastic toxic

- PVC floor "refers to the use of polyvinyl chloride material production floor. Specifically to the polyvinyl chloride and its copolymerization resin as the main raw material, filler, plasticizer, stabilizer, coloring agent and other accessories, in the continuous sheet substrate, the coating process or by rolling or extrusion process and.

- Q: Plastic floor shop no artificial labor costs per square meter

- Buy plastic floor is a choice of material, how to install the plastic floor, plastic floor price, how much money Shanghai plastic flooring, plastic flooring, plastic flooring manufacturers, professional plastic floor, Fuzhou plastic floor, plastic floor thickness, plastic floor green yet,

- Q: With this plastic floor mat bed can not? Will not have any impact on people

- This floor is not allowed to use!! The utility model relates to a plastic floor leather, which belongs to the soft floor, which is made of polyvinyl chloride resin as the main raw material, and is added with appropriate auxiliary agent. Plastic floor leather, although difficult to burn, self extinguishing, but at high temperatures, will decompose harmful gases, excessive inhalation, suffocating. Floor leather containing lead compounds, in the use of the process, with the floor leather wear, lead content continues to spread, the formation of lead dust in the air, easy access to infants and young children

- Q: Worried about a long time, plastic aging, small ironExpose the floor.

- General furniture set foot nails, there is no problem.Because, in general, the furniture will not often move, feet nail support role, and the plastic nails are relatively thick, no problem

- Q: What is the difference between hard and soft plastic floor construction

- If I tell you, will you kill me? Well, tell you, in fact, the difference is not big, not fire

- Q: I would like to ask, can be affixed to the plastic floor tiles on the floor? The key is the room elevation uneven, generally have a difference of about 1 cm, the specific construction process?Do you know? Thank you, online, etc..

- The tiles can be spread on the floor, but the high ground surface roughness is not high at the end of 2 mm, 2 mm high as bottom difference with plastic floor foaming, high bottom difference obviously uneven, finally to rework, also have an impact on the life of the plastic floor! I suggest you do the ground put plastic floor, the following is our factory production and supply of products! The first price, the second material, third material odor (smell the heavier the price cheaper), the quality of the fourth accessories, the price of fifth accessories, the construction materials of the sixth, the material life of the seventh, after service

- Q: What is the material of the plastic foam plate

- The general use of four roller mill factory plasticized PVC, after the pressure of the surface is smooth and smooth, cooling after the edge of the strip is the product

- Q: Plastic floor can be spread in the bathroom

- A commercial floor (children's glue) children's floor (PVC floor) plastic floor1, commercial floor material PVC (real name: PVC floor)2, commercial floor PVC wood material

- Q: Our hostel is covered with plastic foam, so it's hot now

- Foam pad a quilt on a mat mat effect is very good

Send your message to us

Rubber wood floor decking for outdoor made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords