Waterproof rubber floor tiles in garden from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

一. Structure of Waterproof rubber floor tiles in garden

Item | Waterproof rubber floor tiles in garden -- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

二.Main Features of Waterproof rubber floor tiles in garden

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

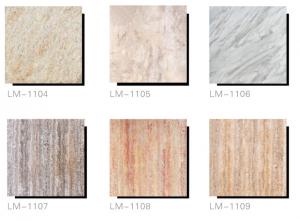

三.Waterproof Hollow Outdoor WPC Decking Made In China Images

四.Waterproof rubber floor tiles in garden Specification

Name | Waterproof rubber floor tiles in garden |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

五.FAQ of Waterproof rubber floor tiles in garden

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: How to remove the plastic protective film on the floor angle

- For a long time, then use the extension heating, and then tear down. This will not damage the appearance of ceramic tile.

- Q: Plastic floor construction technology

- 1, construction materials, construction direction to confirm the construction materials should be the same batch number. Room temperature and material to adapt (adsorption operation).

- Q: EVA plastic floor and PVC plastic floor which is good

- You don't know what is the use of hanging material, I think it is a good floor, PVC

- Q: Floor mounted mats are not ordinary plastic films?

- Wood flooring, acceptance and use of standard requirements, in the mat below paving a layer of plastic film, seam overlapping 20mm, and tape seal, in the geothermal conditions, even if the tape is moisture degumming, it is difficult to influence the floor, can more effectively prevent the harm of moisture on the floor. Therefore, it is necessary to lay plastic film in the geothermal environment.

- Q: What a pig with plastic floor to sell, how much money

- Farmers - Sheng - Le plastic drain board it is unique1: the temperature difference between day and night plastic is smaller than iron, is conducive to the health of piglets and sows, so as to avoid temperature and cold or scald.2: the surface of the manure board matte treatment, increase the contact surface, improve friction, so as to prevent the fall of injured animals.3: washing machine can be used to wash the high-pressure water gun, made into a day without cracks, should not be hidden dirt.4: the company's production of plastic drain board made of pure raw materials, white shiny surface, high quality, durable.5: the plastic plate is suitable for conservation, piglets in farrowing crate bed, bed, sheep dog cage Quanshe dung floor

- Q: Solid wood flooring on the back of plastic paper, why

- Mainly for moisture, but also pest control Damp proof

- Q: What is the material of the plastic foam plate

- The general use of four roller mill factory plasticized PVC, after the pressure of the surface is smooth and smooth, cooling after the edge of the strip is the product

- Q: I asked about the "plastic" floor tile paving method, please describe its steps?

- Key tiles is flat ground, otherwise very easy to open or damaged floor brick. There are a lot of glue to the ground plate, can choose their own. Shop paste must be from the center to the surrounding, and some of the glue scraping after the need to be static 1 ~ 2 minutes after use. After sticking, the glue in the seam should be wiped off

- Q: Household PVC anti-static plastic floor

- Appearance like marble, with a good decorative effect. Applicable to the telecommunications, electronic industry, computer room, computer room, clean house and other requirements of purification and anti-static places.

- Q: PVC plastic floor can be used as a kitchen operating room, right?

- Seems to be floor paint How do I know what it is?

Send your message to us

Waterproof rubber floor tiles in garden from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords