Melt Extract Stainless Steel Fiber RPC Dedicated Copper Military Engineering Use Steel Fiber

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: China (Mainland)

Brand Name: cnbm

Model Number: KEYOU1820

Material: Copper, Copper

Brand: cnbm

Feature: engineering steel fiber

Tensile strength: >2800MPa

Diameter: 0.18----0.30mm

Length: 6---20mm

Fulfilled standard: GJ/T3064-1999,YB/T151-1999,ASTM A820-90

Uasage: tunnels,bridges,airport road surface

Packing: in 20kg to 1 carton

Quality: good

Product features

glued steel fiber together in a row ,is used with cement for construction

oncrete steel fiber is specifically to enhance concrete in its hardened state ,the uniform distribution of steel fiber throughout the concrete greatly improve concrete bonding and tensile strength ,additionally it provides exceptional load stability and durability ,as reliable and efficient concrete reinforcement material

it is widely ued in buildings ,bridges ,thin roo engineering ,highway etc.

1.Material:high quality low carbon steel wire,copper coated

Diameter:0.18mm --0.3mm

Length: 6mm-20mm

Tensile strength:>2850Mpa

2.Feature:Excellent tensile, bending and shearing strength, resistance

against cracking, impact and fatigue.

3.Use:It is widely used for buildings, road surface, bridges, tunnels,

airport road surface, water conservancy projects, military

engineering, and all kinds of building products.

Specifications

length :20-60mm

diameter :0.5MM-1.2MM

tensile strengh:>1100Mpa

| diameter | length | tensile strength | |

| 0.5mm | 35mm | 1100Mpa | |

| 0.75 | 60mm | 1100Mpa | |

| 0.9 | 60m | 1100Mpa |

engineering steel fiber

1.it made from from wire coated copper

2.binding and shearing strength

3.Tensilestrength>2800

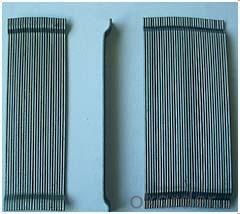

Picture

Adhesion into a row

any type steel fiber

FAQ

we can produce any type steel fiber and of course we can make production according to your requirement

we have specilize in this field for almost 10 years ,with good quality and competitive price

- Q: Can melt extract stainless steel fiber be used in roller-compacted concrete (RCC)?

- Yes, melt extract stainless steel fiber can be used in roller-compacted concrete (RCC). RCC is a type of concrete that is compacted using rollers, which provides a denser and more durable finished product. The addition of stainless steel fibers in RCC can enhance its mechanical properties, such as resistance to cracking and improved flexural strength. Melt extract stainless steel fibers are produced by melting stainless steel and then rapidly extracting it into fine fibers. These fibers have high tensile strength, corrosion resistance, and can effectively distribute stresses within the concrete matrix. As a result, they can enhance the performance of RCC by improving its resistance to shrinkage, impact, and fatigue. Furthermore, melt extract stainless steel fibers are easily dispersed in the concrete mixture and can be evenly distributed throughout the RCC during the compaction process. This ensures that the fibers are well-bonded with the concrete matrix, providing uniform reinforcement and preventing the formation of cracks. In summary, the use of melt extract stainless steel fiber in roller-compacted concrete is a suitable option to enhance its mechanical properties and overall durability. However, it is important to consult with concrete experts and conduct proper testing to determine the appropriate dosage and fiber length for the specific RCC application.

- Q: Can melt extract stainless steel fiber be used in industrial flooring applications for shotcrete?

- Yes, melt extract stainless steel fiber can be used in industrial flooring applications for shotcrete. Shotcrete is a construction technique where concrete is pneumatically sprayed onto a surface, providing a quick and efficient way to create a durable and strong floor. Adding stainless steel fiber to the shotcrete mix can enhance the overall performance and durability of the flooring system. Melt extract stainless steel fiber is made by melting stainless steel and then rapidly extracting it into fine fibers. These fibers are known for their high tensile strength, corrosion resistance, and toughness. When added to shotcrete, they help to improve the crack resistance, impact resistance, and overall durability of the flooring. In industrial settings, where floors are subject to heavy loads, impact, and abrasion, the use of stainless steel fiber in shotcrete can provide significant benefits. It helps to minimize cracking, improve resistance to wear and tear, and increase the overall lifespan of the flooring. Additionally, stainless steel fiber can also enhance the fire resistance of the shotcrete flooring, making it suitable for industrial environments where fire safety is a concern. Overall, melt extract stainless steel fiber can be an excellent choice for industrial flooring applications in shotcrete. It offers improved performance, durability, and fire resistance, making it a reliable option for industrial settings that require robust and long-lasting flooring solutions.

- Q: What are the properties of melt extract stainless steel fiber?

- Melt extract stainless steel fiber is a type of fiber that is formed through the extraction process of molten stainless steel. It possesses several properties such as high temperature resistance, excellent corrosion resistance, good mechanical strength, high electrical conductivity, and thermal conductivity. Additionally, it has a long lifespan, is non-magnetic, and can be easily blended with other materials, making it suitable for various applications in industries like construction, automotive, textiles, and electronics.

- Q: Can melt extract stainless steel fiber be used in precast tunnel segments?

- Yes, melt extract stainless steel fiber can be used in precast tunnel segments. These fibers are commonly used in precast concrete products as they provide reinforcement and improve the overall durability and strength of the structure. Melt extract stainless steel fibers have high tensile strength and excellent corrosion resistance, making them suitable for use in harsh environments, such as tunnels. They can enhance the crack resistance and impact resistance of the tunnel segments, thus increasing their longevity and reducing maintenance needs. Additionally, the use of stainless steel fibers can help improve the fire resistance of the tunnel segments, ensuring the safety of the structure and its occupants. Overall, melt extract stainless steel fibers are a reliable and effective solution for reinforcing precast tunnel segments.

- Q: What is the recommended fiber volume fraction for melt extract stainless steel fiber in concrete?

- The optimal fiber volume fraction for melt extract stainless steel fiber in concrete may differ based on the specific application and desired performance characteristics. Typically, a recommended range of around 1-2% is suggested. This range effectively improves the concrete's tensile strength and crack resistance, while still allowing for proper workability during the mixing and placement process. To determine the ideal fiber volume fraction for the concrete application, consulting the manufacturer's guidelines and recommendations as well as considering the project requirements is crucial.

- Q: Is melt extract stainless steel fiber compatible with different types of cement?

- Yes, melt extract stainless steel fiber is compatible with different types of cement. It can be used in both Portland cement and other types of cement, such as slag cement, fly ash cement, or blended cements. The stainless steel fibers are added to the cement mixture to enhance its performance and improve its durability. These fibers can effectively control cracking and provide reinforcement to the cement matrix, resulting in increased tensile strength and resistance to impact and fatigue. Therefore, melt extract stainless steel fiber is a versatile material that can be used with various types of cement to enhance their properties and performance.

- Q: Can melt extract stainless steel fiber be used in earthquake-resistant concrete structures?

- Certainly, earthquake-resistant concrete structures can utilize melt extract stainless steel fiber. Renowned for their exceptional ductility and high tensile strength, stainless steel fibers are an ideal choice for bolstering the toughness and durability of concrete. The inclusion of these fibers in concrete enhances its ability to withstand cracking, shrinkage, and spalling during seismic events. The utilization of stainless steel fibers in earthquake-resistant concrete structures plays a crucial role in mitigating the adverse effects of earthquakes. Acting as reinforcement, these fibers augment the concrete's strength and hinder the propagation of cracks. This reinforcement fortifies the overall structural integrity of the concrete, rendering it more resistant to the dynamic forces unleashed by earthquakes. Furthermore, melt extract stainless steel fibers possess a high melting point, corrosion resistance, and exceptional thermal stability. These attributes render them suitable for long-term implementation in hostile environments, such as earthquake-prone regions. These fibers remain intact over time, ensuring the concrete structure's long-lasting durability and efficacy. Additionally, melt extract stainless steel fibers have undergone rigorous testing and have been proven to enhance the seismic performance of concrete structures. They conform to various international standards, such as ASTM and ACI, guaranteeing their quality and reliability. These fibers have successfully been employed in a diverse array of earthquake-resistant applications, including bridges, tunnels, high-rise buildings, and industrial structures. In conclusion, melt extract stainless steel fiber can indeed be employed in earthquake-resistant concrete structures. Its exceptional tensile strength, ductility, and resistance to cracking make it an outstanding reinforcement material for fortifying the durability and seismic performance of concrete. By incorporating stainless steel fibers into concrete, engineers can effectively bolster the resistance of structures to seismic forces, ensuring the safety and longevity of infrastructure in earthquake-prone regions.

- Q: How does melt extract stainless steel fiber affect the impact resistance of shotcrete?

- Shotcrete's impact resistance is greatly enhanced by melt extract stainless steel fiber. Shotcrete, which is typically used in construction and repair projects, is a high-strength concrete material that is sprayed onto surfaces. The inclusion of stainless steel fibers in shotcrete increases its tensile strength and toughness, rendering it highly resistant to impact and dynamic loads. Manufactured through a specialized process involving the melting of raw materials and their rapid extraction into thin, elongated fibers, melt extract stainless steel fibers are then incorporated into the shotcrete mix, ensuring even dispersion throughout the material. These fibers create a three-dimensional reinforcement network within the shotcrete, providing enhanced resistance to cracking and fragmentation when subjected to impact. The stainless steel fibers in shotcrete act as micro-reinforcements when confronted with impact forces, effectively absorbing and distributing the energy throughout the material. This prevents the formation and propagation of cracks, leading to improved impact resistance. The fibers also increase the shotcrete's ductility, allowing it to absorb more energy before failure. Furthermore, the corrosion resistance of stainless steel fibers ensures the long-term durability and performance of the shotcrete. These fibers do not rust or deteriorate over time, even in harsh environmental conditions, further enhancing the overall impact resistance of shotcrete. In conclusion, the addition of melt extract stainless steel fiber significantly enhances shotcrete's impact resistance. The fibers reinforce the material, prevent crack formation, and improve its toughness and ductility. Consequently, shotcrete with stainless steel fibers is an excellent choice for applications where impact resistance is of paramount importance, such as tunnel linings, retaining walls, and protective barriers.

- Q: What is the effect of melt extract stainless steel fiber on the cracking behavior of concrete?

- The effect of melt extract stainless steel fiber on the cracking behavior of concrete is generally positive. When added to concrete mixtures, stainless steel fibers can enhance the overall performance and durability of the concrete by reducing cracking. The incorporation of melt extract stainless steel fibers into concrete helps to improve the tensile strength and ductility of the material. As a result, it enhances the concrete's resistance to cracking under different types of loading, such as shrinkage, thermal expansion, and external forces. Stainless steel fibers act as reinforcement within the concrete matrix, effectively bridging any cracks that may occur. This bridging effect helps to prevent the propagation of cracks, limiting their size and minimizing the potential for further damage. It also increases the overall toughness and energy absorption capacity of the concrete. Furthermore, melt extract stainless steel fibers can also improve the overall durability of concrete by reducing the likelihood of corrosion. Stainless steel is highly resistant to corrosion, even in harsh environments, which helps to protect the concrete from degradation and prolong its service life. Overall, the addition of melt extract stainless steel fibers to concrete can significantly improve its cracking behavior. By enhancing tensile strength, ductility, and durability, these fibers contribute to a more robust and long-lasting concrete structure.

- Q: Can melt extract stainless steel fiber improve the resistance of concrete to sulfate attack?

- Yes, melt extract stainless steel fiber can improve the resistance of concrete to sulfate attack. Stainless steel fibers have high corrosion resistance and can enhance the durability and strength of concrete by reducing cracking and improving its resistance to chemical attacks such as sulfate attack.

Send your message to us

Melt Extract Stainless Steel Fiber RPC Dedicated Copper Military Engineering Use Steel Fiber

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords