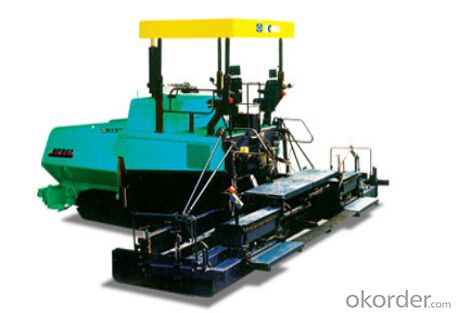

RP602/RP802 multi-functional paver,Power transmission technique: high-efficient and powerful

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Item | Unit | RP802 |

|---|---|---|

| Basic paving width | m | 3 |

| Max. paving width | m | 8 |

| Max. paving thickness | mm | 380 |

| Paving speed | m/min | 0~14 |

| Travel speed | km/h | 0~3.0 |

| Theoretical productivity | t/h | 600 |

| Hopper capacity | t | 13 |

| Gradeability | % | 20 |

| Pavement evenness | mm/3m | 3 |

| Cross slope error | % | ±0.03 |

| Crown adjustment range | % | 0~3 |

| Diesel engine model | BF4M1013C | |

| Diesel engine power | kw | 118 |

| Diesel engine speed | r/min | 2300 |

| Diesel oil tank capacity | L | 230 |

| Overall weight | t | 16.5~23.5 |

| Dimension | mm | 6230×3000×3855 |

| Vibration frequency | Hz | 68~71 |

| Screed heating mode | ||

| Material level control mode | ||

| Automatic Leveling Control |

| Item | Unit |

|---|---|

| Screed model | 575(RP802) |

| Type | Vibrating tamper, vibration, electrical heating |

| Stretch mode | Hydraulic stretch |

| Width range | 3.0-8.0m |

| Vibrating tamper rotate speed | 0-1500r/min |

| Vibration frequency | 4mm |

RP602/RP802 multi-functional paver can be applied to the paving of basic stabilized material and surface material. The machine adopts independent right drive and left drive, micro-computer control, and the telescopic screed with single vibrating tamper (RP802 is equipped with pulse vibration). The material level is controlled by ultrasonic sensing technique, featuring good stability in low-speed paving, even material feeding, high preloading compactness, good pavement evenness, and easy operation. It can absolutely meet the construction requirements.

Technique features

Power transmission technique: high-efficient and powerful

Deutz water-cooled diesel engine with strong power adopts high-pressure pump structure, featuring good diesel oil atomization and economical efficiency, long service life, and extensive application range.

The hydraulic pump and motor of Linde and Rexroth adopted have long service life, featuring big driving torque, low load rate, and reliable performance.

Control technique: stable and precise

Material feeding adopts synchronous drive, and the rotate speed is controlled by full proportional control. The material level adopts ultrasonic control technique which can control the height of the material level stably. The manual gearshift adopts infinitely variable control.

Speed control of material distribution: the manual gearshift and automatic gearshift can be switched freely.

Electronic automatic leveling ensures higher evenness. Many sensing modes and high automaticity can meet the construction requirements of high-grade roads.

Digital micro-computer control can pre-select the speed. Adopt the constant speed automatic control technique, ensuring the paving speed not impacted by the load. During moving, the paving speed and travel speed can be switched freely.

Material feeding and distribution technique: reliable and durable

Strong material distribution capacity: It adopts 360mm coarse pitch, Φ420 large diameter blade, and 28BH reinforced drive chain, the drive capacity is higher 25% than the similar products.

The material distribution box and chain adopt high-intensity design, which can supply strong transmission power. The maximum power transmission capacity of the material distribution shaft is 5000Nm, which can achieve full buried distribution, greatly reducing the segregation.

There are two reverse blades in the middle of the material distribution box, reducing the middle segregation zone.

Screed technique: mature and reliable

Mature and reliable hydraulic telescopic screed: the reasonable dimension match of the telescopic cylinder and sleeve features the excellent glide accuracy and good reliability, ensuring the paving quality.

3-point suspension mechanism ensures stable stretch and retraction

The infinitely adjustable vibration frequency (575 screed) meets the requirements of different working conditions.

Adopt the electrical heating, featuring safety, environment protection, and convenience.

Performance advantages

Excellent configuration

The key parts such as diesel engine, hydraulic pump, hydraulic motor, hydraulic valve, travel reducer, micro-computer controller, bearings, hydraulic pipe joints, hydraulic tube and hose, and filters are imported from European countries, ensuring the durability and reliability of the machine.

Simple maintenance

Central controlled operation features simplicity and reliability. All the operating components are installed on the instrument box, the instrument box is moveable.

There are numbers on all the electrical circuits, which is convenient to check and maintain.

The side cover and engine hood is easy to open, and the components that need to be maintain usually are easy to access to.

The travel drive device adopts outboard cover, which is convenient to maintain.

Excellent performance

The maintenance-free crawler travel device composed of track rollers and rubber track shoes is durable, and doesn’t damage the roads.

The imported automatic centralized lubricating system prolongs the service life of the bearings in high-temperature positions, greatly reducing the amount of maintenance and improving the working efficiency.

- Q: A piece of machinery valued at $20,000 depreciates at a rate of 9% yearly. How long will it take until it has a value of $10,000? (Express your answer to the nearest tenth.) its not 7.4

- 20000 / (1.09)^x = 10000 x = 8.043 years Remember 100 * 1.09 * 0.91 = 99.19 ... NOT 100

- Q: tell me!

- There are lots of things tha fall under that category. The guillotine, the electric chair... Take your pick. Or be more specific.

- Q: What does the food machine contain? [mechanical equipment problems]

- Two, food machinery for fruit and vegetable machinery to dairy equipment to oil equipment to tobacco equipment to slaughter machinery to cooking equipment to 1.0 food brewing equipment equipment to rice machinery to 1.0 1.0 candy beverage machinery mechanical baking equipment to meat processing equipment to 1.0 mechanical biscuits leisure food equipment 1.0 1.0 1.0 condiment condiment equipment equipment meat processing equipment to other machinery 1.0 1.0 1.0 mechanical rice bean equipment, baking equipment 1.0 1.0 brewing equipment

- Q: could anyone provide me with a diagram please .

- This is entirely product dependent. Some products must be harvested quickly and then processed in some way or the quality will start to deteriorate as soon as it is disconnected from its life support system. This would include things like green beans or other vegetables that are to be frozen or canned as close to the harvest location as possible. Other items have an inverse relationship to the speed as far as final quality is concerned, and in some cases within the limits of the harvesting machine, it makes no difference. You need to be more specific to get a good answer to this question. I would also have to make an assumption that this is a harvesting machine, not a soil prep or planting machine.

- Q: but has a heavy ball on the hook and is used to knock buildings or other structures down? My little boy wants to know its name.... thank you!10 points for the fastest and true answer.thanks

- Well you pick up the phone and dial the phone number for a crane with a wrecking ball on the end of it seriouslly I don't think they have a name other than the wrecking crane and that's nothing more than a crane with a wrecking ball hope this helps your little one

- Q: Are democrats the oilers of the machinery that the terrorist intend to pilot to our destruction?

- W/O a doubt, the problem is that they themselves dont see it, they feel the currnent situation is all Bush's fault. Where would we be now without him in office? In Iran they are counting on the demorcratic leader ship to withdraw and not confront Iran on their ambitions to dominate with terror the region. We will rue the day we turned soft on this issue, we will then see the similarities between now and 1933. But it will be too late. Then you had moths to gear up for war, now with technology it is a different story.

- Q: I ve been going to school for HVAC for about a month now. And I was just wondering if anyone had any tips on reading schematics or wiring the machinery up. ( besides make sure the power is off) Each day I get it a little more but I was just wondering if any experts had some tips. Also how is the pay when you get out of school? Please don't tell me to go to salarey I just wanted to know for someone with 1st hand experience. I live in Ma. Thanks in advance

- When working with schematics just remember that all electrical circuits have to have 5 components 1) a source ( ac or dc) 2) a load (maybe a lightbulb) 3) protection ( fuse or circuit breaker) 4) conductors (wires) 5) a switch. Once you know what all of your components are you shouldn't have any trouble following the lines on the schematic. As far as pay is concerned, it all depends on salaries in your state. I don't know what they are in MA. Try calling some electrical contractor in your area and do a salary survey with the. Hope this helps.

- Q: to start a brewery plant , where can i get machinery(complete plant setup) and what is the economical way to go, second hand, new or other options? please give details abt Suppliers, Plant contracters etc

- good luck with that. sasly probably asking here is wrong place to find out. Those that would know unlikely to be answering here. Best of luck in your new business tho.

- Q: And what does taking flu medicine have to do with perfoming operations?

- Medicine knocks u out during ur surgery and u dont feel a thing and and they put flu medicine because you have big cuts and after surgery you in a hospital and u could get anything in that hospital

- Q: a. mRNAb. tRNAc. ribosomesd. amino acidse. RNA polymerase

- except Vitamin A and olive oil! I think I read it somewhere! you see I am smart! :)

Send your message to us

RP602/RP802 multi-functional paver,Power transmission technique: high-efficient and powerful

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords