Round Steel 5115 Steel Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Round Steel 5115 Steel Bars

Products Details

1. good mechanical property

2. high temper resistance

3. hardened and tempered steel

4. 12-250mm/200~650mm

| Material standardized according to | 5115 round steel round bar |

| Unfinished products manufactured | Pipes - profiles - squares |

| Properties | Excellent mechanical features - good workability on high-speed automatic machines with easy fragmentation of the shavings made by the tool |

| Typical applications | used for making heavy loading and sectional gear shaft,gear,connecting rod,eccentric shaft,rear axle shaft of car,parts of steam turbine,etc |

Chemical composition (%)

| C | Cr | Si | p | Mn | Ni |

| 0.37~0.45 | 0.90~1.20 | 0.17~0.37 | ≤0.035 | 0.90~1.20 | ≤0.030 |

Specifications: (approximate values)

| Quenching Temp | 860 ±15 °C |

| Cool Media | Oil |

| Tempering Temp | 600 ±15 °C |

| Cooling Media | air |

Mechanical features

| Tensile Strength (MPA) | Yield Strength(MPA) | Elongation(%) | Reduction In Area(%) | Impact Energy(J) | Hardness(HB) |

| ≥1080 | ≥ 930 | ≥ 12 | ≥ 45 | ≥ 63 | ≥217 |

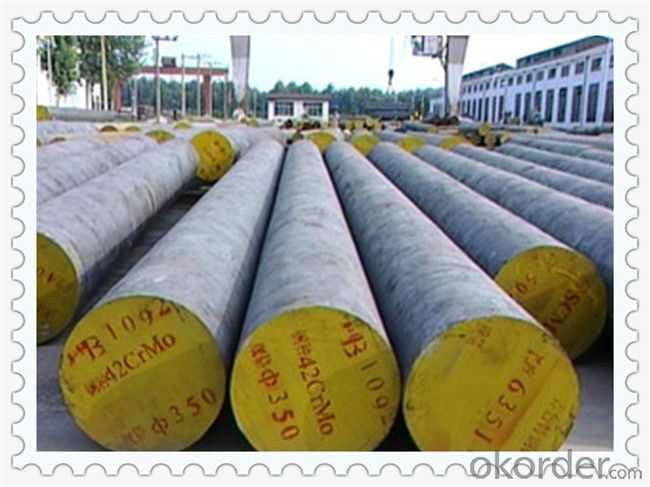

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

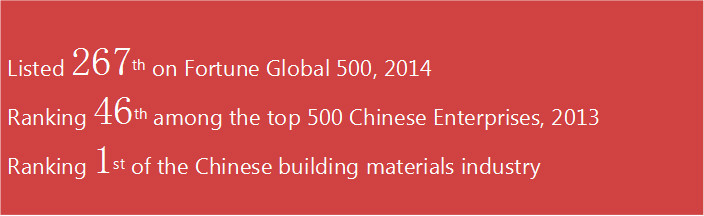

Company Information

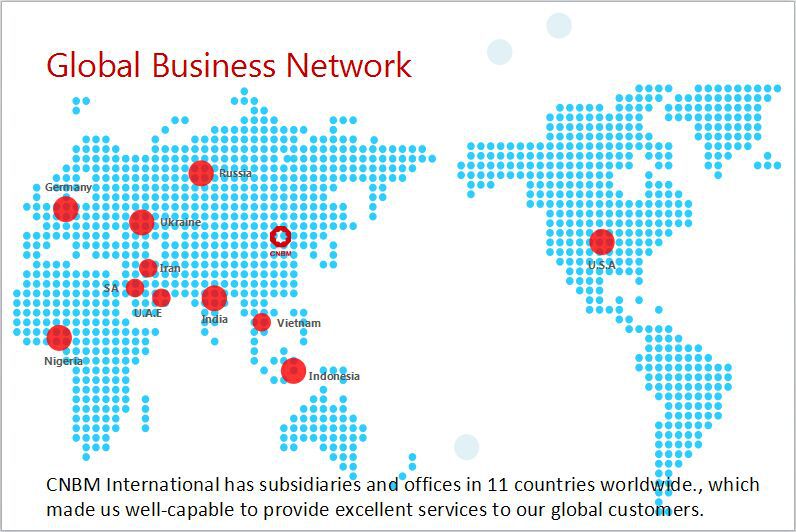

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What are the different grades of alloy steel round bars for automotive applications?

- Automotive applications commonly utilize alloy steel round bars due to their exceptional strength, durability, and resistance to wear and corrosion. The grading of these bars is typically based on their chemical composition, mechanical properties, and appropriateness for specific automotive uses. Here are several distinct grades of alloy steel round bars frequently employed in automotive applications: 1. 4140/42CrMo4: Renowned for its high tensile strength, good toughness, and excellent fatigue strength, this grade of alloy steel round bars is extensively employed in gears, crankshafts, axles, and suspension components. 2. 8620: Offering exceptional hardenability, this grade of alloy steel round bars can be subjected to heat treatment to attain high strength and toughness. It is commonly utilized in shafts, gears, and camshafts. 3. 4340: Known for its impressive strength and toughness, this grade of alloy steel round bars provides good wear resistance and can be heat treated to achieve even greater hardness and strength. It is often used in connecting rods, crankshafts, and high-stress components. 4. 52100: This high carbon, chromium alloy steel is renowned for its outstanding hardness and wear resistance. It is commonly employed in applications such as bearings and races that require high strength and durability. 5. 316L: Recognized for its exceptional corrosion resistance, particularly in harsh environments, this grade of alloy steel round bars is frequently utilized in automotive applications like exhaust systems, where resistance to corrosion is crucial. 6. 4340M: Specifically designed for high-performance automotive applications, this modified version of the 4340 grade offers improved fatigue strength and toughness. It is suitable for demanding applications, including high-performance engine components. These examples represent only a few of the various grades of alloy steel round bars employed in automotive applications. The selection of a specific grade depends on the requirements of the application, including desired strength, toughness, wear resistance, and corrosion resistance.

- Q: Round bar, flat steel, not reinforced

- Round steel: 5.5-25 mm small round bars are mostly supplied by straight strips. They are commonly used as reinforcing bars, bolts and various mechanical parts. They are more than 25 millimeters of round steel. They are mainly used in the manufacture of mechanical parts or as seamless steel tube billets.

- Q: What is the maximum silicon content allowed for steel round bars?

- The maximum silicon content permitted in steel round bars may differ based on the particular grade and application of the steel. Nonetheless, in general, the majority of standard carbon and alloy steels utilized in round bars usually have a maximum silicon content ranging from 0.35% to 0.45%. Going beyond this threshold can result in adverse consequences for the mechanical properties of the steel, including diminished toughness and heightened brittleness. To ascertain the precise maximum silicon content permitted for a specific steel grade and intended use, it is crucial to refer to the applicable industry standards and specifications.

- Q: Can steel round bars be anodized?

- No, steel round bars cannot be anodized. Anodizing is a process that is specific to aluminum and its alloys.

- Q: What are the different machining processes used for steel round bars?

- There are several machining processes commonly used for steel round bars, depending on the desired outcome and specifications of the project. Some of the most common machining processes for steel round bars include: 1. Turning: Turning is a machining process where the round bar is rotated and a cutting tool is used to remove material, creating a desired shape or size. This process is commonly used to reduce the diameter of the round bar or to create precision cylindrical shapes. 2. Drilling: Drilling involves creating holes in the steel round bar using a rotating cutting tool called a drill bit. This process is often used to create holes for bolts, screws, or other fasteners. 3. Milling: Milling is a machining process that involves removing material from the surface of the steel round bar using a rotating cutting tool with multiple teeth. This process is used to create flat surfaces, grooves, or complex shapes on the round bar. 4. Grinding: Grinding is a process where abrasive particles are used to remove material from the steel round bar, creating a smooth surface finish or achieving specific tolerances. It is commonly used to refine the surface finish or to remove any imperfections. 5. Thread rolling: Thread rolling is a process used to create external threads on the steel round bar. A hardened steel die is pressed against the rotating round bar, causing the material to flow and form the desired threads. 6. Cold drawing: Cold drawing is a process where the steel round bar is pulled through a die to reduce its diameter and improve its surface finish. This process is used to create precise dimensions and improve the mechanical properties of the steel round bar. 7. Heat treatment: Heat treatment is not a machining process itself, but it is often used in conjunction with machining to enhance the properties of the steel round bar. Heat treatment processes such as annealing, quenching, and tempering can be used to improve hardness, strength, and toughness. These are just a few of the many machining processes that can be used for steel round bars. The specific process chosen will depend on factors such as the desired shape, size, surface finish, and mechanical properties required for the application.

- Q: Can steel round bars be used in the manufacturing of household appliances?

- Household appliances can indeed make use of steel round bars. Steel, being a versatile and durable material, is widely employed in a variety of industries, including the manufacturing of appliances for homes. The construction of appliance frames, support structures, and even internal components can all benefit from the utilization of steel round bars. Its high strength and resistance to corrosion make steel an excellent choice for ensuring the longevity and durability of household appliances. Moreover, steel can be easily molded and shaped to precise dimensions, allowing for the creation of appliances with intricate designs. In summary, incorporating steel round bars into the manufacturing process of household appliances helps to produce products that are of superior quality, reliability, and longevity.

- Q: What are the main differences between wrought round steel, hot rolled round steel and cold drawn round steel? Where are they used separately?

- Round steel three processing methods are more common, should be very wide surface. Hot rolled round steel, used in construction and general hardware parts processing is very common.

- Q: Can steel round bars be used in the food processing industry?

- Yes, steel round bars can be used in the food processing industry. Steel is a common material used in various industries due to its strength, durability, and resistance to corrosion. In the food processing industry, steel round bars are often used for equipment such as food mixers, conveyors, and cutting tools. These bars are typically made from stainless steel, which is a specific type of steel that contains chromium and other elements to enhance its resistance to corrosion and staining. Stainless steel is non-reactive and does not impart any flavors or odors to the food being processed. Furthermore, it is easy to clean and maintain, making it suitable for use in food processing facilities where hygiene is of utmost importance. However, it is important to ensure that the steel round bars used in the food processing industry meet the necessary standards and regulations to ensure the safety of the food being processed.

- Q: How are steel round bars made?

- Steel round bars are made through a process called hot rolling. It involves heating a large rectangular steel billet until it reaches a malleable temperature. The heated billet is then passed through a series of rolling stands, which progressively reduce its thickness and shape it into a round bar. The first step in the hot rolling process is heating the billet in a furnace at extremely high temperatures, typically around 1200 to 1300 degrees Celsius. This heat makes the steel more pliable and easier to shape. Once the billet is heated, it is fed into a rolling mill. The mill consists of a series of rollers that gradually reduce the thickness and elongate the billet. As the billet passes through each set of rollers, it is squeezed and stretched, gradually forming a round shape. The number of passes through the rolling mill depends on the desired final size and shape of the round bar. During the rolling process, the steel bar is also cooled to prevent overheating and ensure proper metallurgical properties. This can be done through a water spray or air cooling system. After the bar has been shaped and cooled, it is cut into desired lengths. The cut bars are then subjected to further processes such as straightening, surface treatment, and quality testing. These additional steps ensure that the steel round bars meet the required specifications and standards. Overall, the process of making steel round bars involves heating a steel billet, passing it through a series of rolling stands to shape it into a round bar, cooling it, and then cutting it into desired lengths. This process allows for the production of strong and durable round bars that find various applications in industries such as construction, manufacturing, and engineering.

- Q: What are the different types of steel round bars used in the automotive engine components?

- There are several different types of steel round bars used in automotive engine components, each with their own specific properties and applications. 1. Carbon Steel Round Bars: These are the most common type of steel round bars used in automotive engine components. They are known for their high strength and durability, making them suitable for various applications such as crankshafts, connecting rods, and camshafts. Carbon steel round bars can withstand high levels of stress and are capable of withstanding extreme temperatures. 2. Alloy Steel Round Bars: Alloy steel round bars are made by adding different alloying elements such as chromium, nickel, and molybdenum to carbon steel. This enhances their strength, toughness, and wear resistance. Alloy steel round bars are commonly used in automotive engine components like gears, shafts, and bearings where high strength and resistance to wear and fatigue are required. 3. Stainless Steel Round Bars: Stainless steel round bars are highly corrosion-resistant and are often used in automotive engine components that come into contact with corrosive fluids or environments. They are commonly used in applications such as valves, pistons, and exhaust systems. 4. Tool Steel Round Bars: Tool steel round bars are characterized by their high hardness, resistance to abrasion, and excellent toughness. They are commonly used in automotive engine components that require cutting or shaping, such as cutting tools, dies, and punches. 5. High-Speed Steel Round Bars: High-speed steel round bars are designed to withstand high temperatures and maintain their hardness and cutting ability at high speeds. They are frequently used in automotive engine components like drills, milling cutters, and reamers. It's important to note that the specific type of steel round bar used in automotive engine components will depend on the specific application, performance requirements, and cost considerations. Automotive manufacturers carefully select the appropriate steel grade to ensure optimal performance and durability of engine components.

Send your message to us

Round Steel 5115 Steel Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords