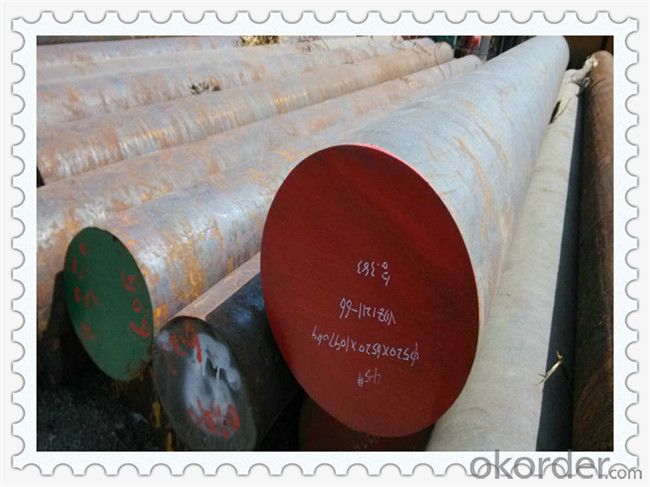

UNS S31050 Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

UNS S31050 Steel Round Bars

| Size | Plate/Sheet:0.3-60mm(THK)*1220mm(WIDTH)*6000mm(LENGTH) |

| Bar:Round:Φ5.5-350mm | |

| Wire:Φ0.1mm-18mm | |

| Seamless Pipe:6mm-219mm(OD)*0.5mm-18mm(WT) | |

| Flange:1/2"-56" | |

| Fitting:According to the drawing. | |

| Material | Austenite Stainless Steel:Rs-2,317L,904L,253Ma(S30815),254SMo(F44/S31254) |

| Biphase stainless steel F51(S31803),F53(S32750),F55(S32760),329(S32900),A4 | |

| Hastelloy C276,Hastelloy C4, Hastelloy C22. Hastelloy B,Hastelloy B-2 | |

| Nitronic50(S20910/XM-19), Nitronic60(S21800/Alloy218), Alloy20Cb-3, Alloy31(N08031/1.4562) | |

| Incoloy825, 309S, Inconel601,A286, Alloy59, 316Ti, SUS347, 17-4PH Nickle201... Ect. | |

| Monel400, Monel k500, Ninckel200, Nickel201(N02201) | |

| Inconel600(N06600),Inconel601(N06601),Inconel625(N06625/NS336),Inconel718(N07718/GH4169),Inconelx-750(N07750/GH4145) | |

| Incoloy800H(NS112/N08810),Incoloy800HT(N08811),Incoloy800(NS111/N08800),Incoloy825(N08825/NS142), Incoloy901,Incoloy925(N09925),Incoloy926 | |

| 1J50,1J79,3J53,4J29(F15),4J36(Invar36) | |

| GH2132(incoloyA-286/S66286),GH3030,GH3128,BH4145(inconelx-750/N07750),GH4180(N07080/Nimonic80A) | |

| Product range | Bolt,nut,screw,washer, thread rod ,flange, fitting, seamless tubes, round bar, plate, wire |

| Standard | GB, JIS, DIN, UNS, ASTM, AISI |

| Logo | JYSS, also according to client’s requirements |

| MOQ | 1pcs at least, also according to size and material |

| One stop purchase | we help you with one stop purchasing, we could manufacture fasteners, flanges and also pipe fittings on these exotic materials. |

| OEM Accepted | Yes |

| Mill test certificate | Yes |

| Inspection report | Yes |

| Payment term | L/C T/T |

| Packing details | wodden case or as per customer requirement |

| Exported countries | United States, Germany, Saudi Arabia, South Korea, etc |

| Production Flow | Raw materials → Inspection of raw materials → Cutting → Heating → Forging stamping- |

| Drilling → Machining → Heating → Treatment → Washing → Non-destructive examination | |

| → Finished product Inspection |

What are the characteristics of UNS N08926/ 1.4529/ 2.4361/ Incoloy 926 ?

1. Super austenitic stainless steel is superior to ordinary stainless steel, it can be used for containing high concentrations of chloride media occasions.It has excellent corrosion resistance to stress corrosion caused by Chlorine ion, also has perfect pitting and crevice corrosion resistance.

2.Application: seawater Super austenitic stainless steel is better than ordinary stainless steel.

3.It can be used in some circustances that contain high concentrations of chloride ions in the medium, stress caused by the chloride ion corrosion, pitting corrosion and crevice corrosion has excellent corrosion resistance.

- Q: Are steel round bars susceptible to cracking?

- Cracking in steel round bars can occur under certain circumstances. Factors that contribute to cracking include high stress levels, improper heat treatment, and the presence of impurities or defects in the material. Cracking is also more likely with sudden temperature changes or excessive loading. It is worth noting that the susceptibility to cracking varies depending on the grade and composition of the steel. Low carbon or mild steel is generally less prone to cracking compared to higher carbon or alloy steels. To prevent cracking, it is crucial to handle and store steel round bars properly. This includes avoiding dropping or mishandling the bars and storing them in a dry, controlled environment to prevent corrosion. Proper heat treatment processes, such as annealing or tempering, can improve the structural integrity of steel round bars and reduce the risk of cracking. Regular inspections and testing for defects or impurities can help identify and address issues before they lead to cracking. In conclusion, while steel round bars can be susceptible to cracking, taking appropriate precautions and using proper manufacturing and handling techniques can minimize the risk and ensure the bars' integrity.

- Q: What are the different types of steel round bar sizes?

- Steel round bars come in a variety of sizes, each serving different purposes and applications. The most common sizes for steel round bars range from 1/8 inch to 24 inches in diameter. These sizes are typically measured in inches, with each increment representing a larger diameter. For smaller projects or more intricate designs, steel round bars ranging from 1/8 inch to 1 inch are often used. These smaller sizes are commonly found in jewelry making, crafting, and smaller construction projects. On the other hand, steel round bars ranging from 1 inch to 24 inches are utilized for larger-scale applications such as structural support, manufacturing, or industrial projects. These larger sizes provide enhanced strength and durability, making them suitable for heavy-duty use. It should be noted that steel round bars are also available in metric sizes, which are measured in millimeters. Metric sizes are commonly used in regions that follow the metric system, such as many countries in Europe and Asia. Choosing the appropriate size of steel round bar depends on the specific requirements of the project, including load-bearing capacity, structural integrity, and overall design. It is advisable to seek advice from an engineer or industry professional to determine the most suitable size for your particular application.

- Q: Can steel round bars be used for making steering linkages?

- Yes, steel round bars can be used for making steering linkages. Steel round bars are commonly used in various mechanical applications due to their strength and durability. They offer the necessary stability and rigidity required for steering linkages, making them a suitable choice for this purpose.

- Q: Can steel round bars be used for drive shaft applications?

- Yes, steel round bars can be used for drive shaft applications. Steel round bars are often used for their high strength and durability, making them suitable for transmitting torque and rotational power in drive shafts. However, the specific type of steel and its characteristics should be considered to ensure it meets the required mechanical properties and performance standards for the intended application.

- Q: How do you prevent scaling of steel round bars during heat treatment?

- To prevent scaling of steel round bars during heat treatment, there are several measures that can be taken: 1. Use a protective atmosphere: Heat treatment can be carried out in a controlled atmosphere, such as in a furnace with a controlled gas environment. This prevents the exposure of the steel bars to oxygen, which is the primary cause of scaling. 2. Apply a protective coating: Coating the steel round bars with a protective substance, such as a refractory material or a thin layer of paint, can help prevent scaling. This coating acts as a barrier between the steel and the oxygen in the atmosphere, reducing the chances of scaling. 3. Use a reducing atmosphere: Instead of using a normal atmospheric environment, heat treatment can be conducted in a reducing atmosphere. This involves introducing gases like hydrogen or nitrogen into the furnace, which react with the oxygen to create a more controlled environment and prevent scaling. 4. Control the heating rate: Rapid heating can lead to increased scaling due to the sudden exposure of the steel to high temperatures. By controlling the heating rate, such as using a gradual ramp-up in temperature, scaling can be minimized. 5. Limit the exposure time: Minimizing the time that the steel round bars are exposed to high temperatures can help prevent scaling. This can be achieved by optimizing the heat treatment process and ensuring that the bars are not held at elevated temperatures for longer than necessary. 6. Clean the surface before heat treatment: Prior to heat treatment, it is crucial to remove any contaminants or residues from the surface of the steel round bars. This can be done through mechanical cleaning methods like wire brushing or chemical cleaning techniques, ensuring a clean surface that is less prone to scaling. By implementing these preventative measures, the scaling of steel round bars during heat treatment can be effectively minimized, leading to improved quality and performance of the treated bars.

- Q: Can steel round bars be used in the aerospace manufacturing industry?

- Yes, steel round bars can be used in the aerospace manufacturing industry. Steel round bars are commonly used in various aerospace applications such as structural components, landing gear, engine components, and fasteners. The high strength and durability of steel make it suitable for these critical aerospace applications. Additionally, steel round bars can be easily machined and formed into complex shapes, allowing for customization and precise engineering requirements in the aerospace industry. Furthermore, steel's resistance to corrosion and its ability to withstand extreme temperatures make it a reliable choice for aerospace manufacturing. Overall, steel round bars are a versatile and widely used material in the aerospace industry due to their strength, durability, machinability, and resistance to corrosion.

- Q: 1, three, two, steel, wire rod, round steel what is the difference?

- Steel is commonly known as hot rolled ribbed bar, belonging to the small steel steel, mainly used for steel reinforced concrete structure frame. In use, some mechanical strength, bending deformation property and welding performance are required. The raw steel billet for the production of threaded steel is carbon structural steel or low alloy structural steel which is treated by calm melting, and the finished steel bar is delivered in hot rolling forming, normalizing or hot rolling state.

- Q: Can steel round bars be used for making staircases?

- Yes, steel round bars can be used for making staircases. They provide durability, strength, and a modern aesthetic appeal to the staircase design.

- Q: How do steel round bars perform under impact or shock loading?

- Steel round bars generally perform well under impact or shock loading due to their high strength and toughness. The inherent properties of steel, such as its ability to absorb and distribute energy, make it highly resistant to deformation or failure when subjected to sudden forces or impacts. Additionally, the uniformity and reliability of steel's microstructure contribute to its consistent performance and durability in such loading conditions.

- Q: What are the different types of connections used with steel round bars?

- There are several types of connections commonly used with steel round bars, including threaded connections, welded connections, and mechanical connections such as couplers or splice sleeves. These connections are used to join steel round bars together in various applications, providing strength and stability to the overall structure.

Send your message to us

UNS S31050 Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords