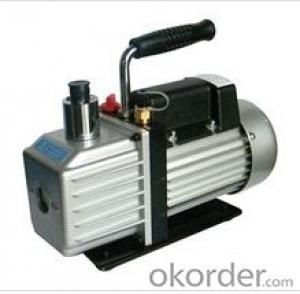

Rotary Vane Vacuum Pump 2X Bipolar Series Rotary Vane Vacuum Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction:

2X-type rotary vane vacuum pump for the two-stage structure, its performance from the high pressure stage and low pressure stage parts, it's connected to a vacuum suction device or vacuum vessel, the gas inside the container will be a lot of suction and discharge when running. When the equipment to obtain vacuum, high-level chip will be closed exhaust valve, high pressure level and the gas will be transferred to the second level, and by the second stage suction and discharge, vacuum equipment available certain vacuum. Technical parameters of the vacuum pump 6 × 10-2pa. According to user usage, can be equipped with vacuum booster, 2X rotary vane vacuum pump as before the pump, due to the booster pump suction force to strengthen, before the pump continuous extraction can make your device a higher vacuum.

Application:

The rotary vane vacuum pumps used in metallurgy, chemical industry, electric light vacuum, vacuum coating, food packaging, pharmaceuticals, plastic, electronics, and other fields dry use.

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is the recommended air pressure for different types of inflatables?

- Different types of inflatables have varying recommended air pressures depending on the specific item. Here are some suggestions for common inflatables: 1. Pool floats and inflatable toys: Generally, these should be inflated to a lower air pressure, typically around 1-2 PSI. It is important to avoid over-inflating them as it can strain the seams and cause damage. 2. Air mattresses: Most air mattresses suggest an air pressure of approximately 6-8 PSI. However, it is crucial to refer to the manufacturer's instructions for specific requirements, as certain models may have different recommendations. 3. Balloons: Regular latex balloons typically require an air pressure of about 0.5 PSI. To prevent bursting, it is crucial to adhere to the recommended guidelines and avoid over-inflation. 4. Inflatable boats and kayaks: The air pressure for these inflatables may vary based on size and material. Generally, it is advisable to maintain a range of 2-3 PSI. Nonetheless, accurate guidelines should be sought from the manufacturer's instructions. 5. Gym/exercise balls: The recommended air pressure for gym or exercise balls depends on their size and intended use. In general, most exercise balls require an air pressure of approximately 4-5 PSI. However, it is important to verify the specific instructions provided by the manufacturer. Remember to consult the manufacturer's instructions for precise and specific air pressure recommendations for your particular inflatable. Over-inflation or under-inflation can affect performance, durability, and safety, so following the recommended guidelines is crucial.

- Q: Can an air pump be used for inflatable beach balls?

- Yes, an air pump can be used to inflate beach balls.

- Q: Can an air pump be used for inflating air mattresses with flocked tops?

- Yes, an air pump can be used to inflate air mattresses with flocked tops. An air pump is a versatile device that can be used to inflate various inflatable objects, including air mattresses. The flocked tops on air mattresses provide a soft and comfortable surface, but they do not affect the ability of the air pump to effectively inflate the mattress. Simply attach the appropriate nozzle or adapter to the air pump, secure it onto the air valve of the mattress, and turn on the pump to start inflating. The flocked top will not interfere with the air pump's ability to fill the mattress with air.

- Q: How does an air pump handle different types of hoses?

- An air pump is designed to handle different types of hoses by utilizing various adapters and fittings. These adapters and fittings allow the air pump to connect to hoses of different sizes and types. The first step in handling different types of hoses is to identify the specific type and size of the hose. This can be done by referring to the manufacturer's specifications or by physically measuring the hose's diameter. Once the type and size of the hose are determined, the appropriate adapter or fitting is selected. These adapters and fittings come in different shapes and sizes to accommodate different hose types. For example, there could be adapters for connecting a pump to a standard garden hose, or fittings for connecting to a smaller air hose used in pneumatic tools. The selected adapter or fitting is then attached to the outlet of the air pump. This is usually a threaded connection that ensures a secure and airtight seal. The other end of the adapter or fitting is designed to fit the specific type of hose being used. It may have a threaded connection, a quick-release mechanism, or a barbed end that requires a hose clamp for a secure attachment. Once the adapter or fitting is properly attached to the air pump and the hose, the air pump can be operated to inflate or extract air from the connected system. The pump's pressure and airflow are transferred through the adapter or fitting into the hose, allowing it to perform its intended function. In summary, an air pump handles different types of hoses by using adapters and fittings that are specifically designed to connect to various hose sizes and types. These adapters and fittings ensure a secure and airtight connection, allowing the air pump to effectively inflate or extract air from the connected system.

- Q: Are there air pumps suitable for medical use?

- Yes, there are air pumps specifically designed and suitable for medical use. These air pumps are often used for medical devices such as compression stockings, inflatable splints, or air mattresses for patients with limited mobility or who require pressure relief.

- Q: The car is changing the oil, there is not clean flow, and finally take the pump blow down?

- Hello, usually in the last place, almost after pumping, so that relatively clean, do not recommend the use of air guns for blowing, general air guns will have moisture

- Q: Can an air pump be used for inflatable pool accessories?

- Yes, an air pump can be used for inflatable pool accessories. An air pump is a versatile tool that can be used to inflate various items, including inflatable pool toys, floats, and accessories. It provides a quick and efficient way to inflate these items, saving time and effort compared to manual inflation. However, it is important to ensure that the air pump is compatible with the valves of the specific pool accessories being inflated. Different accessories may have different valve types, so it is essential to check the compatibility before attempting to use an air pump.

- Q: What is the maximum temperature an air pump can withstand?

- The specific model and manufacturer determine the maximum temperature that an air pump can endure. Nevertheless, the majority of air pumps are engineered to function between -10°C to 40°C (14°F to 104°F). To guarantee optimal performance and avoid potential harm, it is vital to refer to the user manual or communicate with the manufacturer to ascertain the precise maximum temperature limit of a specific air pump. Going beyond the suggested temperature threshold can result in overheating, reduced efficiency, and potentially irreversible damage to the air pump.

- Q: How is an air pump powered?

- An air pump is typically powered by either electricity, such as by plugging it into an electrical outlet, or by a battery, which provides the necessary power to operate the pump and generate airflow.

- Q: Can an air pump be used for oxygen supply?

- No, an air pump cannot be used for oxygen supply as air pumps typically do not filter out impurities and do not provide a high enough concentration of oxygen for medical purposes.

Send your message to us

Rotary Vane Vacuum Pump 2X Bipolar Series Rotary Vane Vacuum Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords