Horizontal Double Suction Centrifugal Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

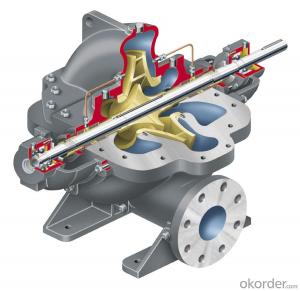

Horizontal Double Suction Centrifugal Water Pump

General Introduction of Horizontal Double Suction Centrifugal Water Pump

According to market needs, Split-case single-stage double suction centrifugal water pump is developed in the broad absorption of advanced technology. Its remarkable characters are as follows: perfect, excellent general model, novel structure, convenient repair. This pump currently produced by our company have fall into more than 40 categories, nearly 400 specification products. We had improved pump impeller and impeller diameter to lead to its impact framework and increasing efficiency. In the spectrum performance range, we can provide any water pump that meets users’ need for pump head and flow.

Sophisticated products and complete quality control, reach domestic advanced standard. We have IS09001 certificate so we can ensure its quality.

This series of water pumps are in accordance with lS02548C, GB321 6C, GB/T5657 standard.

Application of Horizontal Double Suction Centrifugal Water Pump

This pump is widely used in city water supply and drainage, urban water supply; water supply and drainage of central heating system; iron and steel metallurgy, petrochemical refineries, paper mills, oil fields, power plant, airport construction, chemical plants, textile mills, sugar refinery, chemical plant, power plant water supply and drainage, the factory, mine fire water supply system, air conditioning system of water supply, farmland irrigation and drainage, and all other kinds of water engineering.

FAQ

Q: Can your pumps mount Eff.1 motors

A: Currently, only on request though this will shortly be a CNBM standard.

Q: Are your pumps protected against dry running?

A: No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.

Q: How can I get trained on CNBM products?

A: Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

Q: Are your pumps cheaper than those of your competitors?

A: CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

- Q: Are there air pumps suitable for industrial applications?

- Yes, there are air pumps specifically designed for industrial applications. These air pumps are built to handle the demands of heavy-duty industrial use, where large volumes of air need to be pumped continuously. They are typically more powerful and durable compared to air pumps used for residential or commercial purposes. Industrial air pumps are capable of generating high-pressure air and can be used in various applications such as pneumatic tools, manufacturing processes, air compressors, HVAC systems, and wastewater treatment plants. They are engineered to withstand harsh environments, operate at high temperatures, and have longer service life. Additionally, they usually come with advanced features like variable-speed drives, energy efficiency, and remote monitoring to optimize performance and reduce operational costs.

- Q: How efficient are air pumps in terms of inflation speed?

- Air pumps are highly efficient in terms of inflation speed. They are designed to rapidly fill up various inflatable objects such as tires, balls, and air mattresses. With their powerful motors and well-engineered mechanisms, air pumps can quickly deliver a significant amount of air, making the inflation process fast and convenient.

- Q: Can an air pump be used for inflatable exercise equipment?

- Indeed, inflatable exercise equipment, such as stability balls, exercise mats, or yoga balls, can utilize an air pump for inflation. In fact, manufacturers often include their own dedicated air pumps with these items for convenient inflation. These specialized pumps are specifically crafted for use with inflatable exercise equipment and usually come with suitable attachments to ensure a secure and efficient inflation procedure. Nevertheless, it is crucial to consult the manufacturer's instructions or guidelines to confirm if your air pump is suitable for the particular type and size of inflatable exercise equipment you intend to use.

- Q: Can an air pump be used for inflating air loungers with built-in phone holders?

- Yes, an air pump can be used to inflate air loungers with built-in phone holders. Air loungers are typically designed to be inflated using an air pump, as they require a significant amount of air to be filled. The built-in phone holders do not affect the process of inflation, and the air pump can be used to fill the lounger with the necessary amount of air.

- Q: Can an air pump be used for inflatable promotional items?

- Indeed, inflatable promotional items can be easily inflated using an air pump. In fact, utilizing an air pump is considered one of the most effective and convenient techniques for inflating promotional items such as balloons, inflatable characters, or banners. By employing an air pump, a constant and controlled flow of air is provided, allowing for quick and effortless inflation. Moreover, the use of an air pump guarantees that the promotional items are inflated to their desired shape and size. Furthermore, relying on an air pump eliminates the need for manual blowing, which can be both exhausting and time-consuming, particularly when inflating multiple items. All in all, an air pump is an indispensable tool for effectively inflating and maintaining the appearance of inflatable promotional items.

- Q: Now use 80W's WDB air pump, exhaust volume 70L, and burn when carving acrylic. The 3P pump doesn't catch fire, but it is too heavy and reduces the laser heat

- Add an adjustable switch

- Q: How does an air pump prevent water contamination in fish tanks?

- An air pump prevents water contamination in fish tanks by promoting circulation and aeration of the water. It works by drawing in air from the atmosphere and pumping it into the aquarium through a series of tubes and diffusers. This creates bubbles and turbulent water movement, which helps to oxygenate the water and remove harmful gases such as carbon dioxide. The increased oxygen levels in the water are crucial for the well-being of the fish and other aquatic organisms living in the tank. It supports their respiration process, allowing them to extract oxygen from the water and release carbon dioxide. Without adequate oxygen supply, fish can suffocate and die. Furthermore, the air pump helps to break the water surface tension, which allows for the exchange of gases between the aquarium water and the surrounding atmosphere. This exchange helps to rid the water of pollutants and toxins, such as ammonia and nitrogenous waste produced by the fish. These waste products can accumulate in the tank and become harmful to the fish if not removed. By creating water movement and surface agitation, the air pump aids in the removal of these harmful substances by allowing them to escape into the air. In addition to preventing water contamination, the air pump also helps to distribute heat evenly throughout the tank. This is particularly important in larger aquariums where temperature variations can occur. By creating water movement, the air pump helps to mix warmer and cooler water, ensuring a more consistent temperature throughout the tank. This is essential for maintaining the overall health and well-being of the fish. Overall, an air pump plays a crucial role in maintaining a healthy and balanced aquatic environment by preventing water contamination, providing oxygenation, removing harmful gases, and promoting temperature regulation in fish tanks.

- Q: Can an air pump be used for powering air curtains?

- Yes, an air pump can be used for powering air curtains. Air curtains are typically used to create a barrier of air, which helps to separate two different environments while still allowing easy access between them. These curtains are often used in commercial settings, such as retail stores or restaurants, to keep outside air, insects, or dust from entering the interior space. An air pump, which is commonly used to inflate items like balloons or air mattresses, can be used to power the air curtains. The pump works by forcing air into the curtain, creating a continuous stream of air that forms a barrier. The air pump needs to have sufficient power and airflow capacity to generate the desired air curtain effect. It is important to note that the size of the air pump should be compatible with the size and length of the air curtain being used. The manufacturer's guidelines should be followed to ensure proper installation and operation. Additionally, regular maintenance and inspection of the air pump and air curtain system are necessary to ensure continuous and efficient performance. In conclusion, an air pump can be used effectively to power air curtains, providing an efficient and cost-effective solution for maintaining a separation between different environments.

- Q: What is the ideal air pressure for hydroponic systems?

- The air pressure needed for hydroponic systems can vary depending on the setup and the plants being grown. Most hydroponic systems typically require a pressure between 5 and 10 psi (pounds per square inch) to ensure proper oxygenation and nutrient delivery to the plant roots. However, it's important to consider that the specific air pressure requirements may differ based on factors like the type of hydroponic system and the plants being cultivated. For instance, certain plants, like lettuce, thrive in higher levels of oxygen and may benefit from higher air pressure. To determine the ideal air pressure for a hydroponic system, it's recommended to consult the manufacturer's guidelines or seek advice from experienced hydroponic growers. Regular monitoring of the system's oxygen levels and plant health can also help identify if any adjustments in air pressure are needed.

- Q: What are the power requirements for an air pump?

- The power needs of an air pump can differ depending on the particular model and its intended purpose. Generally, air pumps are run by electricity and necessitate either a direct current (DC) or alternating current (AC) power source. For small air pumps utilized in aquariums or small inflatable items, the power needs are typically minimal, varying from 1 to 10 watts. These pumps are designed to be energy-efficient and function on low voltage, usually 12 volts or below. They are frequently powered by batteries or low-voltage power adapters. On the flip side, larger air pumps employed in industrial applications or for inflating sizable inflatable structures may require substantially higher power. These pumps can have power requirements ranging from several hundred watts to several kilowatts. They are usually powered by standard AC power outlets and may necessitate a dedicated circuit to handle the high power demand. It is important to verify the specifications provided by the manufacturer for each specific air pump model to ascertain its power requirements. The power needs are typically stated in terms of voltage (V) and current (A) or wattage (W). Ensuring that the power supply used for the air pump aligns with the specified requirements is crucial to avoid damaging the pump or potential safety hazards.

Send your message to us

Horizontal Double Suction Centrifugal Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords