Raw Materials for Refractory:Rotary Kiln Calcined Bauxite 86 Made in China Supplied by CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DESCRIPTION

QUIKE DETAILS

| Place of Origin: | Henan, China (Mainland) | Shape: | Block , Powder | Material: | Bauxite |

| SiO2 Content (%): | 8% Max | Al2O3 Content (%): | 86%Min | Fe2O3 Content (%): | 2%Max |

| CaO Content (%): | CaO+MgO<0.6< span=""> | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | International standard |

| SiC Content (%): | International standard | Model Number: | 80# 85# 86# 87# | Brand Name: | CNBM |

PACKAGING & DELIVERY

| Packaging Details: | JUMBO BAGS/WOVEN BAGS/ PAPER BAGS (pallets) or as per customers' request! |

| Delivery Detail: | 25 days after buyer's instruction. |

SIZES

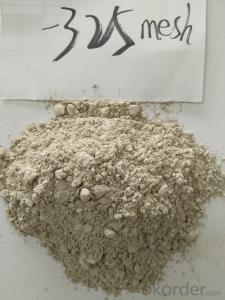

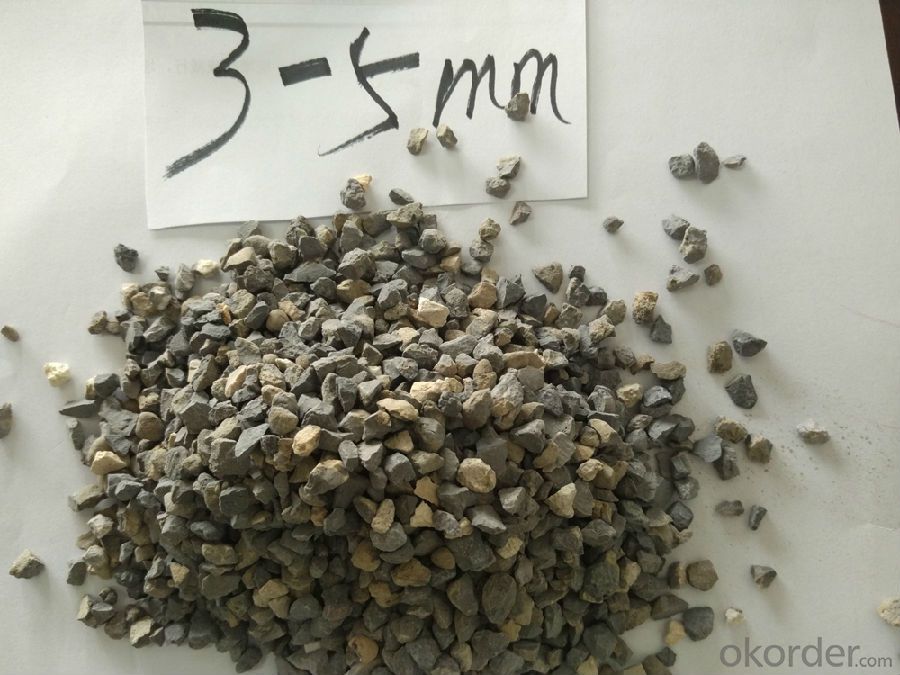

| GRAIN | normaly 0-1/1-3/3-5mm,or as per customers' request |

| POWDER | -200/-220/-325mesh,or as per customers' request |

OTHER GRADES OF RKB

GRADE | CHEMICAL CONTENT,% | PHYCICAL PROPERTIES | |||||

Al2O3,% | Fe2O3,% | TiO2,% | CaO+MgO,% | R2O,% | DENSITY, g/cm3 | WATER ABSORPTION,% | |

GAL-70 | ≥70 | ≤2.0 | - | ≤0.6 | ≤0.6 | ≥2.75 | ≤5.0 |

GAL-80 | ≥80 | ≤2.0 | ≤4.0 | ≤0.5 | ≤0.5 | ≥2.90 | ≤5.0 |

GAL-85 | ≥85 | ≤1.8 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.10 | ≤4.0 |

GAL-88 | ≥88 | ≤1.5 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.15 | ≤4.0 |

GAL-88HG | ≥88 | ≤1.5 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.25 | - |

We can also supply ROUND KINN BAUXITE, SHAFT KILN BAUXITE with many grades.

PICTURES

COMPANY PROFILE

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: Do you know what the main indicators are for the inspection of refractory materials? Thank you very much for your requests and reports

- Porosity, volume density, water absorption, true density, thermal expansion, thermal conductivity and heat capacity.

- Q: How is the division of the fire resistant level of the rock wool board?

- It's like this: China's national standard GB8624-97 divides the combustion performance of building materials into the following grades. Level A: non-flammable building materials. Level B1: flame-retardant building materials. Level B2: combustible?building?materials. Level B3 flammable building materials. section II Combustion performance and fire endurance of building components. First, The combustion performance of buildings of building components. The building is composed of components, such as foundation, walls, lubrication columns, beams, plates, roofs and stairs, ect. Building components are constituted by the building materials, whose combustion performance depends on the combustion properties of the used construction materials. Section One Combustion performance of building components. The building components are divided into three categories according to their combustion properties. First, non-combustible component: the component made by incombustible?materials. The incombustible?material refers to that when meeting the Oxygen in the air, it will not burn.

- Q: What are the materials for refractory materials? What are their names?

- High temperature oxide materials in refractory special applications, such as aluminum oxide, lanthanum oxide, beryllium oxide, calcium oxide, zirconium oxide, refractory compounds, such as carbides, nitrides, borides, silicides and sulfides; high temperature composite materials, including metal ceramics, high temperature inorganic coatings and fiber reinforced ceramics.

- Q: What is the function of refractory material?

- Refractory is a basic material in the field of high temperature technology. Generally, the refractory is used as structural material or lining to resist high temperature in various thermal equipment and high temperature container. In the iron and steel industry and metallurgy industry, coke ovens are mainly composed of refractory materials. Various refractories that meet the requirements are essential in blast furnace for ironmaking, hot stove, all kinds of steel-making furnaces, soaking furnace and heating furnace. Not only the die casting for molten steel needs lots of refractory materials, but also the continuous casting needs some high-quality refractory materials. Without high-quality refractory materials, external refining is also not impossible to achieve. Statistics show that the steel industry is the sector that needs the most refractory. Pyrometallurgy and thermal processing of ferrous metal also needs refractories. All high-temperature furnaces or lining in construction materials industry or other high temperature industries that produce silicate products such as glass industry, cement industry, and ceramics industry must be constructed with refractory materials. All kinds of roasting funaces, sintering funaces, heating furnaces, boilers, flues, chimneys and protective layers in chemical, power and machinery manufacturing industry need refractories. In short, when some kind of structures, devices, equipments or vessels are used under high temperature, they all should utilize refractory to resist the high temperature because those materials will deform, soften and fuse or will be eroded, scoured or broken due to the physical, chemical, mechanical effects, which may stop the operation, affect the production, contaminate processed objects and impact the quality of products.

- Q: How to divide the fire rating standards of insulation materials?

- The fire rating classification standards of insulation materials, 1. Insulation materials with A-level combustion performance: inorganic fiber spraying, rock wool, glass wool, foam glass, ceramic foam, foam cement, close-celled perlite, etc. 2. Insulation materials with B1-level combustion performance: specially-treated extruded polystyrene boards(XPS)/ specially-treated Polyurethane(PU), Phenolics, Polystyrene rubber powder particles,etc. 3. Insulation materials with B2-level combustion performance: Expanded polystyrene sheets(EPS), Extruded polystyrene board(XPS), Polyurethane(PU), Polyethylene(PE), etc.

- Q: I wanna ask what are the acidic refractories?

- Usually, acidic refractory refers to a kind of refractory which contains a amount of silicon?dioxide. There are the following: (1) silica?brick with stronge acidity, unshaped silicious refractory, quartz glass and fused silica combined products; (2) semi-silica refractory with moderate acidity and pyrophyllite refractory; (3) clay-based refractory with weak acidity. The main features of the acidic refractories is resistant to the erosion of acidic substances (acidic residue) in high temperature, but is easy to react with alkaline material (basic slag). zirconite fireproofing material and silicon carbide as the special acidic refractories refractories are also in this category.

- Q: which kind of refractory is commonly used in the industry

- Therefore it is known as special fire-resistant materials, such as yttria, high alumina raw material (sometimes neutral), olivine,which is used for alkalinity furnace, dolomite, and we roughly divided into several categories, beryllia, cerium oxide, these materials have a strong alkaline slag resistance, thorium oxide, lime, serpentine, which is picked from these refractory raw materials. the raw materials of basic refractory materials are mainly magnesia clay and titanium oxide, but because not many sources of raw materials, it can not be widely applied in the refractory industry, and we can analyze which kind of materal is processed by the pulverizer. There are many kinds of refractory materials, rotary?kiln can only be used in particular circumstances. These materials have a variety of slag resistance at different degrees. the main material of special refractories is zirconium oxide. the refractory clay is the most basic and most widely used raw material in the refractory industry.

- Q: Which region use more refractory?

- Tangshan of Hebei province, Jincheng of Shanxi province, Wuxi of Jiangsu province, Wuhan of Hubei province

- Q: What kind of refractory material should be used for common boiler?

- Build by using clay refractory mortar. Common clay brick is used as combustion layer. Xindeyuan Refractory Material, red?brick is used as external wall. Light clay brick is used as thermal insulation layer, thank you.

- Q: Is there a worker in (Jigang refractory plant)?

- Ha ha, base should be rest, you won't give you money, Hugh or those money, endlessly is your dedication. Should be double cease, ah, how do you say four days?. In theory, it's five days off now, and the three day of that is from the chairman to every employee.

Send your message to us

Raw Materials for Refractory:Rotary Kiln Calcined Bauxite 86 Made in China Supplied by CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords