Rotary Kiln Calcined Bauxite 86 Made in China for Refractory with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DESCRIPTION

QUIKE DETAILS

| Place of Origin: | Shanxi, China (Mainland) | Shape: | Block , Powder | Material: | Bauxite |

| SiO2 Content (%): | 8% Max | Al2O3 Content (%): | 86%Min | Fe2O3 Content (%): | 2%Max |

| CaO Content (%): | CaO+MgO<0.6 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | International standard |

| SiC Content (%): | International standard | Model Number: | Rotary Kiln Bauxite86 | Brand Name: | CNBM |

PACKAGING & DELIVERY

| Packaging Details: | JUMBO BAGS/WOVEN BAGS/ PAPER BAGS (pallets) or as per customers' request! |

| Delivery Detail: | 25 days after buyer's instruction. |

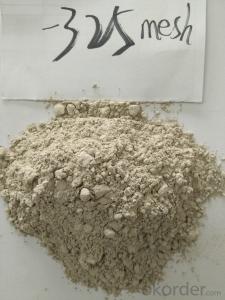

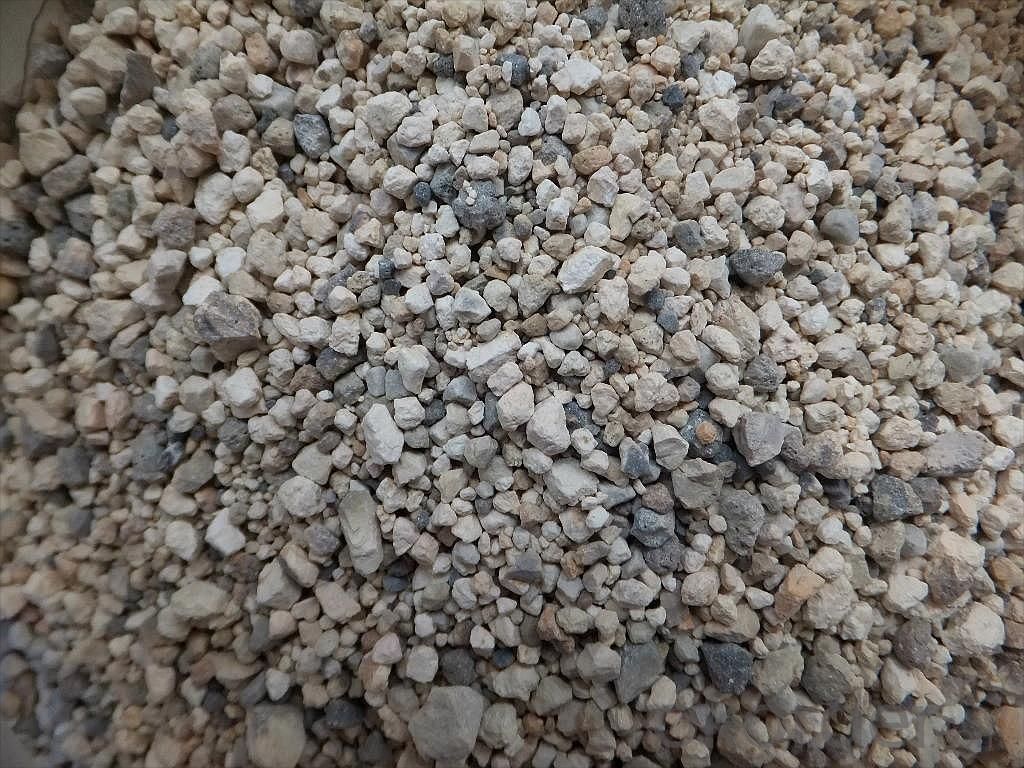

SIZES

| GRAIN | normaly 0-1/1-3/3-5mm,or as per customers' request |

| POWDER | -200/-220/-325mesh,or as per customers' request |

OTHER GRADES OF RKB

GRADE | CHEMICAL CONTENT,% | PHYCICAL PROPERTIES | |||||

Al2O3,% | Fe2O3,% | TiO2,% | CaO+MgO,% | R2O,% | DENSITY, g/cm3 | WATER ABSORPTION,% | |

GAL-70 | ≥70 | ≤2.0 | - | ≤0.6 | ≤0.6 | ≥2.75 | ≤5.0 |

GAL-80 | ≥80 | ≤2.0 | ≤4.0 | ≤0.5 | ≤0.5 | ≥2.90 | ≤5.0 |

GAL-85 | ≥85 | ≤1.8 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.10 | ≤4.0 |

GAL-88 | ≥88 | ≤1.5 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.15 | ≤4.0 |

GAL-88HG | ≥88 | ≤1.5 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.25 | - |

And we can accept other grades as customer's request.

PICTURES

COMPANY PROFILE

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

In line with the business, CNBM International launched E-business platform Okorder.com.

Our goal is to transform CNBM International into the global leading brand in building materials industry within 3 to 5 years through innovation and reform, by strengthening the overall management of supply chain, developing and cultivating both domestic and overseas market, improving the procedure and information system, enhancing the ability to organize resources and to provide value-added services under a professional team and a learning organization.

With the advantages in Cement, Composite Materials, New Building Materials and Engineering, we mainly concentrate on coal, steel and construction equipments and give priority to solar and wind energy development simultaneously utilizing our competitive position on traditional building materials to achieve sales revenue of RMB10 Billion in 2013.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

On July 7th, the US Fortune magazine published the 2014 Ranking List of World Top 500 Enterprises. China National Building Materials Group Corporation (CNBM Group in short) enters into the Fortune Global 500 for the fourth successive time with its operating revenue of 41.03 billion USD, ranking the 267th place, and rising 52 places over last year. Amongst the three building materials enterprises listed in the Fortune Global 500, CNBM ranks the second with promising momentum.

The rapid development of CNBM Group derives from the market-oriented reform of diversified ownership and a series of innovative actions carrying forward the industrial reorganization. Thanks to the exploration into the marketization mode of SOK enterprises (state-owned keyenterprises), CNBM Group reorganized almost a thousand enterprises with limited government capital and hence reactivated a greater amount of social capital, which exerted a positive influence on building material industrial transformation and achieved a win-win situation between China’s national assets appreciation and enterprises development. Now CNBM Group has become a remarkable example in SOK enterprises’ diversified ownership reformation

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: Who can tell me what is neutral refractory?

- Neutral refractories refer to the refractory materials which will not react greatly with both acidic and basic slag at high tempreratures. Such as carbon refractories and chromite refractories. The main components include carbon, silicon carbide, aluminum oxide, chromium oxide and other trivalent oxides, such as carbon refractories and chrome refractories, etc. Strictly speaking, neutral refractories refer only to the carbonaceous refractories, including carbon brick and graphite silicon carbide products, etc.

- Q: What is the strength of high strength refractory material?

- Hefei Jiule decoration is answering your question: Use corundum as aggregate, high alumina cement as binder, mixed with a number of additives prepared, with high strength, and a hydraulic refractory casting material used in hot furnace lining at high temperature.

- Q: How long is the fire endurance of Grade A fire resisting shutter

- The fire endurance of Grade A fire resisting shutter is not lower than 1.20h. Use fire resisting shutter as fire?compartment separation in places where it is difficult to set firewall. When fire resisting shutter whose unexposed surface temperature rise is used as judging condition of fire endurance is used, its fire endurance should not be lower than 3h. When fire resisting shutter whose unexposed surface temperature rise is used as judging condition of fire endurance is not used, individual protection of ?closed automatic water spray system shoule be set at two sides of the shutters and duration of water spray system should not be less than 3.0h.

- Q: What kind of material is refractory fiber?

- Refractory fiber is good infrared radiation material with good thermal capacity and infrared heating effect. The use of firefractory fiber products can effectively save energy. It is an ideal energy-saving material. Practice has proved that using refractory fiber in continuous industrial heating furnace can save energy of over 15%, and using it in interval industrial heating furnace, it can save energy of more than 30%, while increasing productivity and improving product quality. And make the furnace structure light, large-scale with good comprehensive performance. Refractory fiber is soft and flexible and it is also ideal sealing material. As it has good insulation, sound absorption, anti-oxidation, oil and water resistance and easy construction, it is widely used in metallurgy, building materials, petroleum, chemical, shipbuilding, electric power, aerospace and other fields.

- Q: What kind of refractory materials are used in metallurgy industry?

- Argon-blowing rod, siliceous dry vibrating materials, desulfurizer, slag-stopping ball, stainless steel thermal insulating agent with high efficiency, dry vibration material, sizing nozzle heat-insulating panel, chrome refractory , refractory carstables for ladles, magnesia carbon refractory, package castable, siliceous drainage agent, tundish block, iron trough, deoxidizer, compound deoxidizer,silicon manganese alloy , stemming, floating plug,slagging agent. The main materials are as follows: recarburizer, covering agent, intermediate frequency furnace burden, mould fluxes, insulation thin slag agent, skimmer repair material, joint sealant.

- Q: What are the technical requirements for refractories?

- How high the temperature is and what is this refractory?

- Q: What are the application of old refractory bricks?

- It can be used for refractory bricks again, as long as the quality is good. It is much more cost-effective than Bayerite.

- Q: Can anyone tell me which materials are fire-proof high temperature resistant material?

- Fireproof high temperature resistant materials such as: Quartz, tridymite, cristobalite, chalcedony, flint, opal, quartzite, White silica sand, diatomaceous earth, the silicon oxide (SiO2) contained in these siliceous materials is at least 90% . The silicon oxide in some pure raw material can be above 99 %. Siliceous materials are acidic in high-temperature chemokinesis. when existing metallic oxide or contact with metallic oxide, they will conduct chemical actions and conbine into fusible silicates. Therefore, if the siliceous raw material contains a small amount of metal oxide, its heat resistance will be seriously affected..

- Q: what materials can make external wall fireproofing paint have the fireproofing effect

- First, the width of fire barrier is greater than 30CM, and the thickness should be same to the thickness of insulation material. fire barrier zone insulation board must do the whole area sticking construction with the base wall during the construction. fire barrier zone insulation board is required to assistant binding by anchor bolt, anchor bolt must suppress the underlying mesh. fire barrier zone should be set at the upper position of door and window openings, the distance between the low edge of isolation belt and the upper edge of the window must be less than 50cm. When the fire barrier zone is set on the edge of the window, fire barrier zone at the upper part of the window should do flanging when sticking, flanging glass fiber mesh must exceed 10CM than firebreak insulation board. flanging network, underlying network and surface network can not be overlapped or butted at the top of the window. the thermal resistance of fire barrier zone must be half than EIFS thermal resistance in the cold northern areas, while the thermal resistance of fire barrier zone must be three times than EIFS thermal resistance in the hot summer and cold winter area. Cement foam insulation board is recommended to use as external insulation board materials, level A exterior wall cement foam insulation board is a new ultra-lightweight thermal insulation material, with the advantages of lightweight concrete and insulation performance, with characteristics of low production costs, simple process, easy to operate, small product density in 180250kg / m3, high strength, low water absorption and good insulation properties, thermal conductivity of 0.05 ~ 0.07W / m · K and level A non-combustible; it is suitable for external wall insulation and fire isolation belt, and can meet the urgent needs of the market of exterior thermal insulation. With the increase of the intensity of the building fireproofing, the products will become the leading products in building insulation market in the future.

Send your message to us

Rotary Kiln Calcined Bauxite 86 Made in China for Refractory with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords