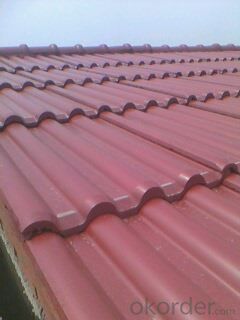

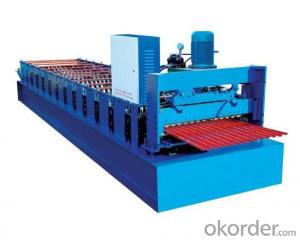

Roofing tile mould Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The first class full-automatic large-size CNC concrete tile moulding machine for roof or floor usage is the most advanced innovative, cost-effective and eco-friendly professional tile forming equipment by far.

Main technical parameters of the first class full-automatic large-size CNC concrete tile moulding machine for roof or floor usage:

| Main technical parameters | Details |

| Voltage | 380 V |

| Rated Power | 12 KW |

| Molding Cycle | 6-8 seconds / piece |

| Molding Pressure | 6500 Kilo Newton |

| Output Per Shift | 2400-3000 pieces |

| Product Specification | 940 x 640 x 15 mm |

| Weight of the Main Machine | 12 Ton |

| Dimension of the Main Machine | 4500 x 1680 x 2650 mm |

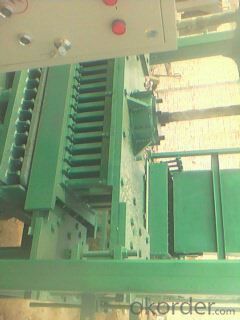

The first class full-automatic large-size CNC concrete tile moulding machine for roof or floor usage includes the following parts:

| Product Name | Model Number |

| one mixer | LK-350 |

| one elevator | LK-1 |

| one main machine | MYW-10 |

| one hydraulic forklift | LK-1 |

| one manual ridge/edge tile making machine | LK |

| 2000 pieces of steel tile moulds | LK |

5 pieces of plastic ridge tile moulds 5 pieces of plastic edge tile moulds | LK |

Working Principle

Mix water, raw material such as cement or coal ash and sand up in proportion and feed the mixture evenly to the main machine of the CNC concrete tile moulding machine, and then under the high pressure of a hydraulic cylinder and a mould, semifinished concrete tiles which become concrete tiles after maintenance and painting are produced. If different moulds such as terrazzo or brick moulds are applied, terrazzos or bricks can be obtained.

Advantages

Advantages of the tiles produced by the first class full-automatic large-size CNC concrete tile moulding machine for roof or floor usage:

1. Unique water-proof structure

2. Easy to construct

3. Strong wind resistance

4. Good heat insulation

5. Freezing-thawing resisting and weathering-resistant

6. Diversified shapes and various colors

Our Services

Customer Service

We have been adhering “honest first,quality for survival”,as the guideline since we founded company 30 years ago.

we always adhere to customer-centric,and concentrate on improving our product quality continually.

Our company built up with strict quality assurance system and constantly improve customer service system,which promote the

quality of pre-sales and after-sales service.

we will try our best to make maximize profits for customers,by perfect equipment & spare supply and timely after-sales service.

We hereby promise:

We always provide reliable products,perfect sales service and strong technical support for you.

1.Pre-sale services:

Act as a good adviser and assistant of customers;help them to get rich and generous returns on their investments.

(1)Introduce company product in details and select appropriate equipment model for customers,according to the scale of their’s

factory.

(2)Free site planning,Design and manufacture products depend on customers’ special requirement;

(3)Provide essential technical support, including project design,personnel training, relevant technical documents, etc

2.During the sales services:

Respect customers;devote ourselves to improving the total value of customers.

(1)The product is 100% full inspection before delivery and ensure the product is qualified.

(2)Help customer consultation determine to draft solving plans and other needed convenience help.

3.After-sales services:

Provide considerate service to minimize customers’ worries.

(1)Provide free installation, debugging and technical training, till ensure that customer can operate the equipment alone.

(2)One year warranty, free maintenance (except for man-made causes of failure)

(3)Provide spare parts and maintenance services lifelong (paid services) and continue to provide the necessary technical

support.

- Q: Can olive nets be used for olive tree frost protection?

- Yes, olive nets can be used for olive tree frost protection. These nets help create a protective barrier around the trees and act as a shield against frost, reducing the risk of damage to the olive trees during cold weather.

- Q: How do olive nets prevent olives from being damaged by windblown debris?

- Olive nets act as a protective barrier, preventing windblown debris from reaching the olives. The nets are tightly secured around the trees, creating a physical barrier that prevents debris from coming into direct contact with the olives. This helps to maintain the quality and integrity of the olives, ensuring they are not damaged by any potentially harmful debris that could affect their taste or appearance.

- Q: Can olive nets be used for table olive production?

- Yes, olive nets can be used for table olive production. These nets are commonly used to protect the olives from birds and other animals, as well as to collect the olives during harvesting. By using olive nets, the olives can be kept clean and free from damage, ensuring higher quality table olive production.

- Q: Are there any specific techniques for preventing olive net damage from hailstorms?

- Yes, there are specific techniques for preventing olive net damage from hailstorms. Some common techniques include installing anti-hail netting that has a smaller mesh size to effectively block hailstones, using overhead sprinklers to create a protective layer of ice on the netting, and employing hail cannons or other hail suppression methods to reduce the intensity of hailstorms. Additionally, timely pruning and maintenance of olive trees can help minimize potential damage to the nets.

- Q: How do olive nets prevent olives from falling prematurely?

- Olive nets prevent olives from falling prematurely by creating a physical barrier that catches the olives as they fall from the tree, ensuring they are not damaged or lost before they are ready to be harvested.

- Q: How do olive nets prevent hail damage to olives?

- Olive nets prevent hail damage to olives by acting as a protective barrier that shields the trees from hailstones. These nets are made from durable and tightly woven materials that can withstand the impact of hailstones. They are installed over the olive trees before hailstorms occur, effectively preventing the hailstones from directly hitting the fruits and causing damage. The nets create a buffer zone that absorbs the impact of the hailstones, reducing the force and minimizing the potential for physical harm to the olives.

- Q: Can plastic bottles drink hot water?

- Plastic of this kind of material is used mainly to pack mineral water, juice, carbonated beverage plastic bottle. Plastic 1, polyethylene terephthalate (PET). This material has poor heat resistance and the maximum use temperature is not more than 70 degrees celsius. Heating or holding water will deform and dissolve harmful substances.Don't use this kind of drink bottled hot water, and don't use it as a cup or storage for a long time. You'd better finish it and throw it away.

- Q: How does an olive net affect the overall fruit texture in the olive grove?

- An olive net plays a crucial role in maintaining the overall fruit texture in an olive grove. By carefully placing the net beneath the trees, it prevents the olives from falling onto the ground, thereby reducing the risk of physical damage and bruising. This ensures that the olives retain their natural firmness and texture, resulting in better quality fruits during the harvesting process.

- Q: Can olive nets be used in both commercial and residential settings?

- Yes, olive nets can be used in both commercial and residential settings. They are commonly used in commercial olive orchards for harvesting and protecting the fruit, but they can also be used in residential gardens or small-scale olive groves for the same purposes.

- Q: Can olive nets be used for olive tree protection against herbicides?

- Yes, olive nets can be used for olive tree protection against herbicides. Olive nets provide a physical barrier that helps prevent herbicides from reaching the olive trees and causing damage. They can effectively shield the trees from herbicide drift, ensuring their protection and health.

Send your message to us

Roofing tile mould Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords