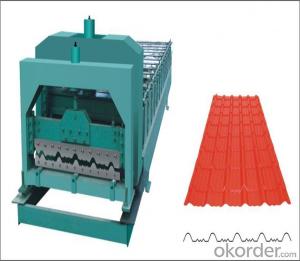

Roller Shutter Forming Machine with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: shutter door roll forming machine

Tile Type: Steel

Use: shutter door

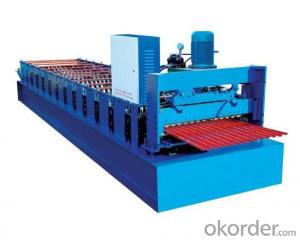

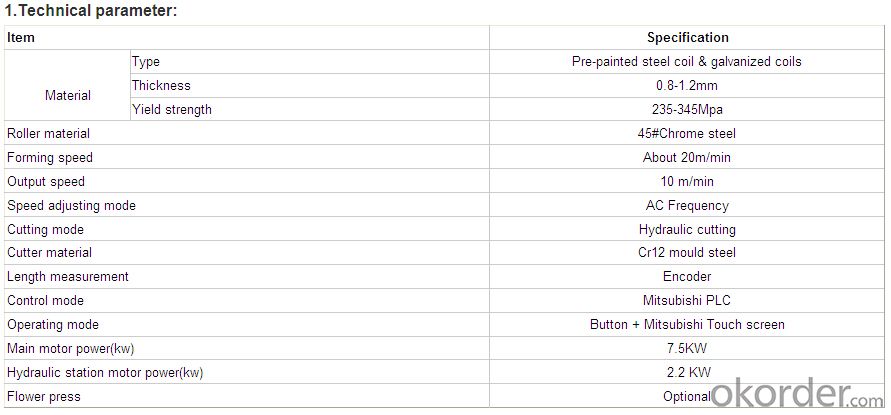

Production Capacity: 10m / min.

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Zhongyuan

Model Number: ZYYX series

Power(W): 7.5KW

Voltage: can be designed according to buyer's requirement

Dimension(L*W*H): 7000X1000x1400MM

Weight: 3500KG

Certification: CE, CE ISO SGS

Warranty: 12 months limited warranty starting from date of delivery

After-sales Service Provided: Engineers available to service machinery overseas

Quality system: ISO9001

Controller system: Mitsubishi PLC

Cutter material: CR12 mould steel, quenched treatment

Cutting style: Automatic hydraulic cutting

Roller material: No.45 steel, plated with chrome on suface.

Shaft for rollers: 55mm dia. solid steel pipe

Guarantee term: first year by free, lifetime services.

Operation language: English or as per client's requirement

Hydraulic power: 2.2KW

Packaging & Delivery

| Packaging Details: | 1. one 20ft container for loading one set of machine with mechanical decoiler; 2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film; 3. Spare parts and some small parts packed in plastic tooling box; 4. All Components Fixed by steel wire with Container. |

|---|---|

| Delivery Detail: | within 50 days |

Why choose this machine?

1.Certificate: ISO 9001, CE,

2. Lifetime services

3. Roller cover with 0.05mm chrome; 55mm diameter solid steel shaft. Lifetime>10years.

4. Introduced Mitsubishi PLC with touch screen to machine controll system.

5. One worker operation (minimum)

6. Heat treatment:Cutting blade. Quenched treatment: Cr12 mould steel cutter

7. Product cut-to-length.

8.Technician overseas installing and training available

- Q: What is the instrument lathe, how to use it?

- Processing the outer circle, the inner circle, cut off, the end face, cut groove, car taper, drilling, reaming, tapping, milling, grinding and other functions.

- Q: How many kinds of machine tools

- NC bending machine, CNC rotary head presses. CNC special machining machine; This machine includes CNC wire (electrode) cutting machine tools, CNC EDM machine tools, CNC flame cutting machine,

- Q: What is 16 lathes

- The main components are: spindle box, exchange gear box, feed box, slide box, knife, tailstock, light bar, screw, bed, bed feet and cooling devices.

- Q: What is the CNC machine?

- Through the arithmetic processing by the numerical control device issued a variety of control signals, control machine action, according to the drawings of the shape and size, automatically the parts processed out.

- Q: Machine operating procedures

- 1, carefully read the shift records, to understand the operation of the last machine and the existence of problems;

- Q: What is the role of a CNC machine lock switch?

- CNC machine tools are digital control machine (Computer numerical control machine tools) for short, is a program control system with automatic machine tools.

- Q: How is the system number defined in machine tool classification?

- Category Lathes Drilling Machines Boring Machines Grinding Machines Gear Machining Machines Thread Machining Machines Milling Machines Planers Punching Machines Broaching Machines Special Machining Machines Sawing Machines Other Lathes

- Q: Shenyang machine i5 machine only how?

- Are imported things, as if the servo motor is Japan, the turret stability should have no problem, this knife in the other models are used.

- Q: What is the advantage of other CNC machine tools compared to other equipment?

- If my answer is helpful to you, please take the best answer, thank you!

- Q: The lathe belongs to the machine? The machine? Other production equipment? The equipment related to the production activity? What kind of classification?

- To the machine equipment category, because the machine is not directly involved in the production, according to the classification of fixed assets, the machine tool process is an expense project, he does not create profits, on the contrary to spend the cost, because you are manufacturing, so this machine process belongs to the auxiliary work class,

Send your message to us

Roller Shutter Forming Machine with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords